Extrusion layered crushing grinding type superfine smashing device

A technology of ultra-fine crushing and grinding devices, applied in cocoa, grain processing, food science, etc., can solve the problems of reducing work efficiency and long action time, and achieve the effect of improving production efficiency, improving crushing efficiency, and conveniently adjusting the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

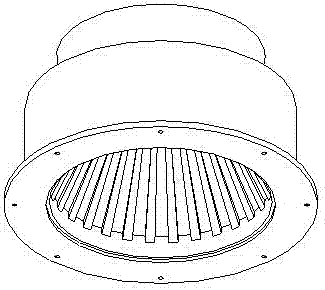

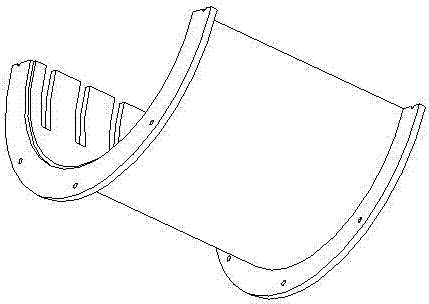

[0027] An extrusion layer crushing grinding type ultra-fine crushing device, comprising a frame 9, a main shaft 1, the main shaft 1 is located on the center line of the frame 9, an extrusion layer crushing device is fixed above the frame 9, and the extrusion layer The crushing device is fixed on the main shaft 1 through the key Ⅰ13, and the grinding device and the discharge device are arranged under the extrusion layer crushing device in turn; the extrusion layer crushing device and the grinding device are fixed on the main shaft 1, and run synchronously under the action of an external motor ;

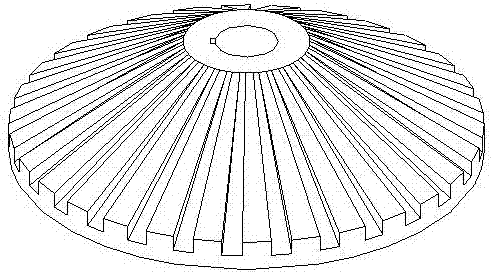

[0028] The extruding layer crushing device includes a feed inlet, and the extrusion layer crushing cylinder 10 is below the feed inlet, and the extrusion layer crushing cylinder 10 is connected to the frame 9 by bolts, and the bottom of the extrusion layer crushing cylinder 10 is provided with There is a layer broken disk 12, which is a hollow conical disk. The layer broken disk 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com