Special-shaped section metal hollow component six-axis free bending forming device and technology analysis method

A technology for hollow components and special-shaped cross-sections, which is applied in the field of six-axis free bending forming equipment for hollow components with special-shaped cross-sections, and can solve the problems of flat cross-sections, limited degrees of freedom, and labor and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

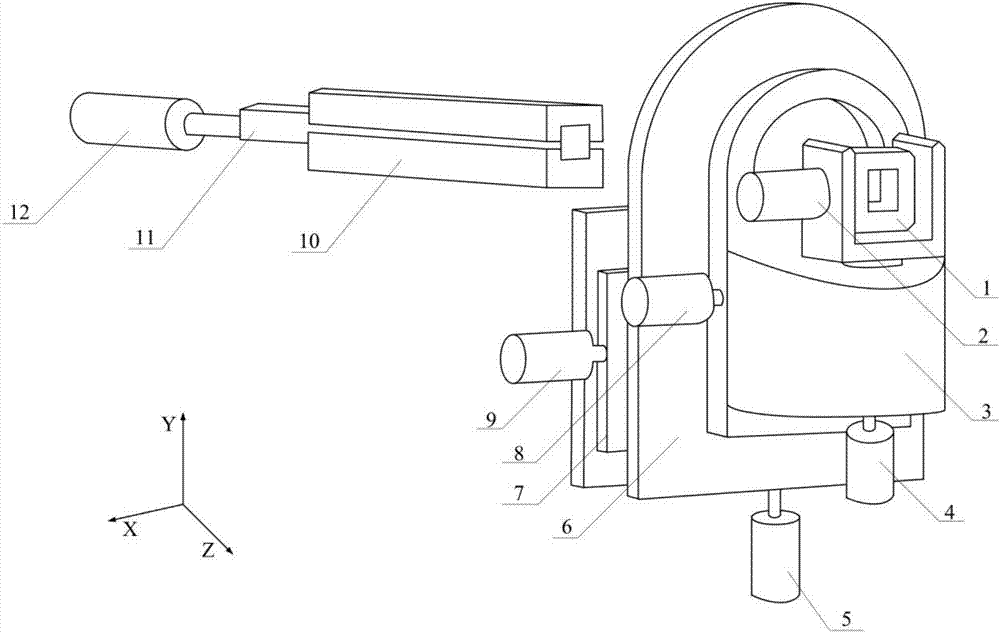

[0097] Step 1), reference figure 2 , for the square tube to be bent, feed the material horizontally at a speed of 10mm / s, start the equipment X-axis motor (9), and make the bending die (1) produce an eccentricity of 1mm in the X-axis direction. Continue to feed the material to obtain the bending radius of the square tube when the eccentricity is 1 mm. Repeat the test to obtain the bending radius of the square tube when the eccentricity is 2mm, 3mm, 4mm, 5mm, 6mm..., and then obtain a series of relationship points between the eccentricity and the bending radius for the square tube;

[0098] In step 2), a series of points obtained in step 1) are fitted to obtain a relationship curve between eccentricity and bending radius for the specific square tube.

[0099] Step 3), will be as figure 2 The three-dimensional geometric model of the square pipe shown is segmented, including straight and curved segments;

[0100] Step 4), obtain the first straight section of the square tube ...

Embodiment 2

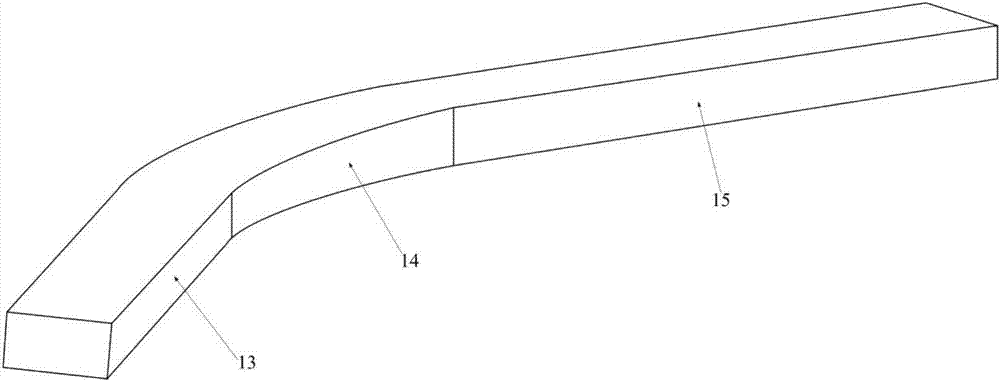

[0127] Step 1), reference image 3 , for the I-shaped cross-section profile to be bent, feed the material horizontally at a speed of 10mm / s, start the X-axis movement motor of the equipment, and make the bending die produce an eccentricity of 1mm in the X-axis direction. Continue to feed the material to obtain the bending radius of the I-shaped cross-section profile when the eccentricity is 1 mm. Repeat the test to obtain the bending radius of the I-shaped section profile when the eccentricity is 2mm, 3mm, 4mm, 5mm, 6mm..., and then obtain a series of relationship points between the eccentricity and the bending radius for the I-shaped section ;

[0128] In step 2), a series of points obtained in step 1) are fitted to obtain a relationship curve between the eccentricity and the bending radius of the specific I-shaped cross-section profile.

[0129] Step 3), will be as image 3 The three-dimensional geometric model of the shown I-shaped section bar is segmented, including the...

Embodiment 3

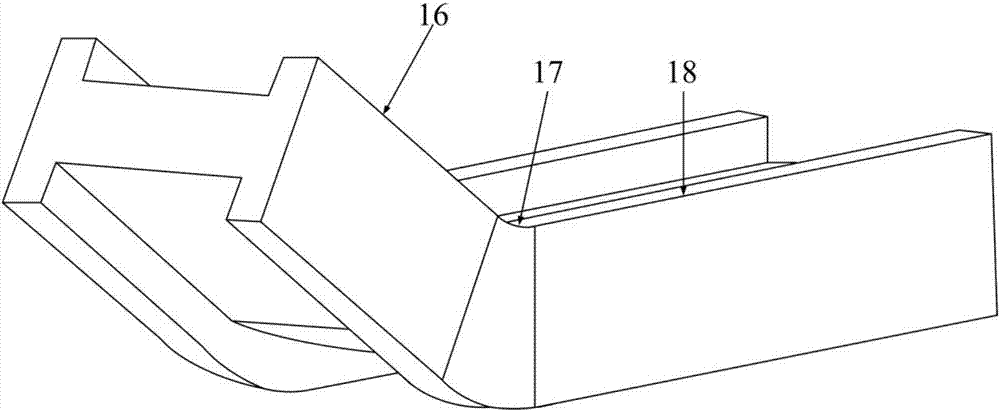

[0157] Step 1), for the to be bent such as Figure 4 The special-shaped cross-section pipe shown is fed horizontally at a speed of 10mm / s, and the X-axis movement motor of the equipment is started to make the bending die produce an eccentricity of 1mm in the X-axis direction. Continuously feed the material to obtain the bending radius of the special-shaped cross-section pipe when the eccentricity is 1 mm. Repeat the test to obtain the bending radius of the special-shaped cross-section pipe when the eccentricity is 2mm, 3mm, 4mm..., and then obtain a series of relationship points between the eccentricity and the bending radius for the special-shaped cross-section pipe;

[0158] Step 2): Fitting a series of points obtained in step 1) to obtain a relationship curve between the eccentricity and the bending radius for the pipe with special-shaped cross-section.

[0159] Step 3), will be as Figure 4 The three-dimensional geometric model of the special-shaped cross-section pipe sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com