Rotary wheel bracket clamp holder device and spinning machining method for large thin-wall curved face product

A processing method and wheel bracket technology, applied in the field of spinning processing, can solve the problems of long production cycle, high cost, large structure, etc., and achieve the effect of improving quality, improving production efficiency, and maintaining smooth surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

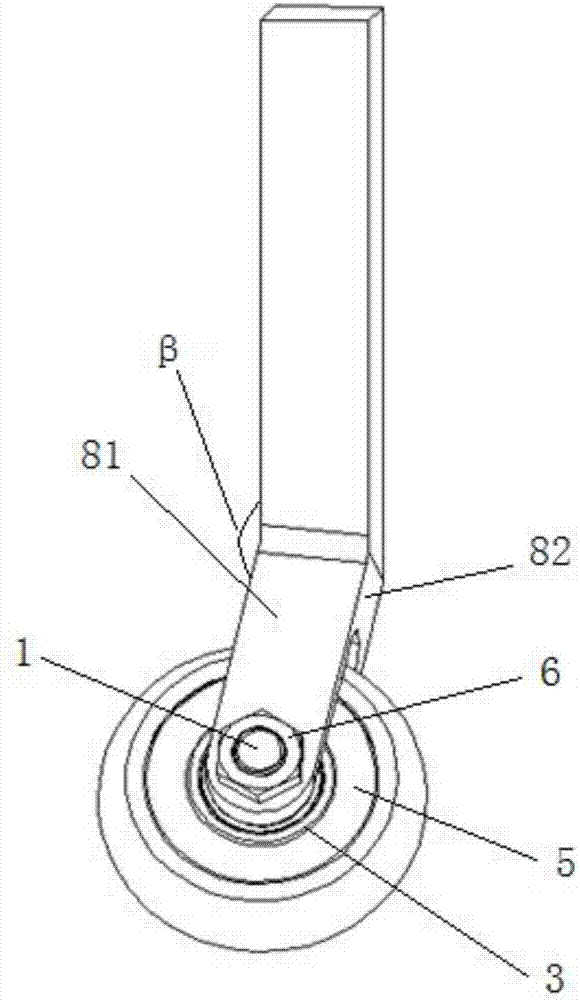

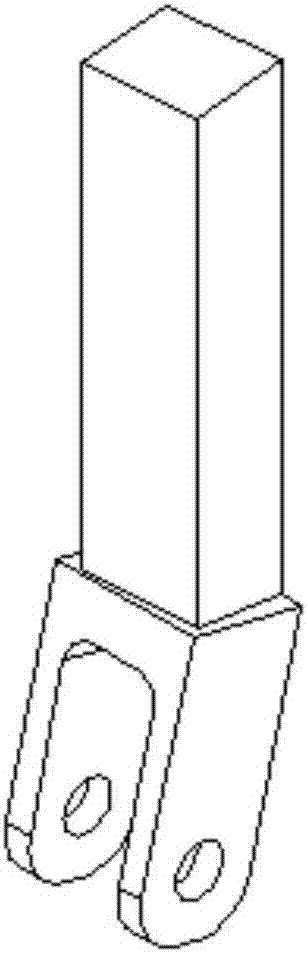

[0037] like figure 1 , 2 As shown, a wheel bracket clamping device includes a knife bar 4, a wheel seat 8 and a spinning roller 7, the knife bar 4 and the wheel seat 8 are integrally formed, and the wheel seat 8 is obliquely fixed on the side of the knife bar 4 At the end, the included angle β between the cutter bar 4 and the wheel seat 8 is an obtuse angle, and the two sides of the spinning roller 7 are clamped with a bearing seat 5, and a bearing 3 is installed in the bearing seat 5, and the spinning roller 7, bearing 3 The bearing seat 5 is arranged in the wheel seat 8, and is connected through the mandrel 1, and the mandrel 1 is locked to the wheel seat 8 by the nut 6.

[0038] A retaining ring 2 is provided between the mandrel 1 and the bearing 3 and between the nut 6 and the bearing 3 .

[0039] The side portion 81 of the wheel seat 8 and the tool bar 4 form an obtuse angle β, and the angle λ formed between the axis of the mandrel 1 and the longer side of the tool bar ...

Embodiment 2

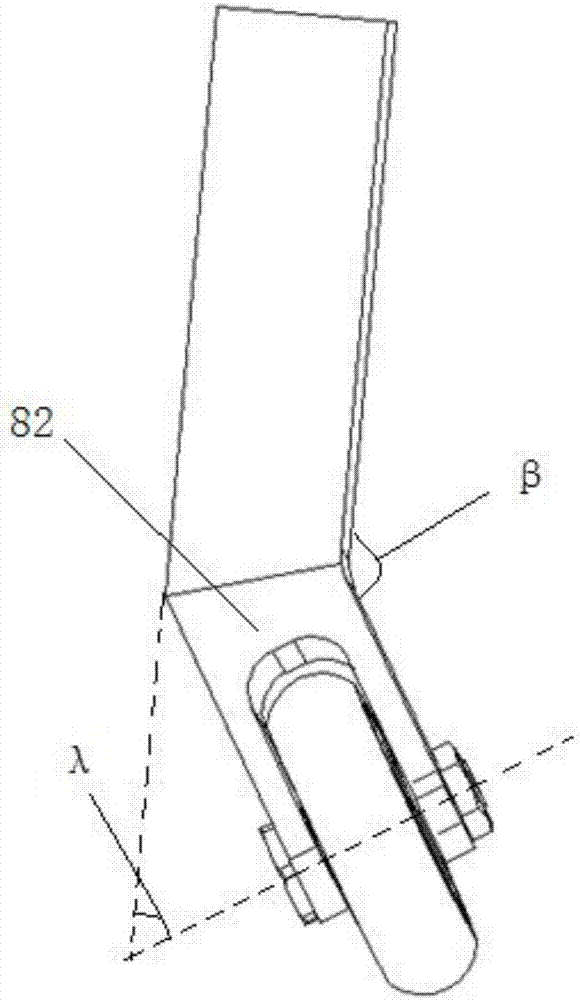

[0043] like image 3 , 4 As shown, a wheel bracket clamping device includes a knife bar 4, a wheel seat 8 and a spinning roller 7, the knife bar 4 and the wheel seat 8 are integrally formed, and the wheel seat 8 is obliquely fixed on the side of the knife bar 4 At the end, the included angle β between the cutter bar 4 and the wheel seat 8 is an obtuse angle, and the two sides of the spinning roller 7 are clamped with a bearing seat 5, and a bearing 3 is installed in the bearing seat 5, and the spinning roller 7, bearing 3 The bearing seat 5 is arranged in the wheel seat 8, and is connected through the mandrel 1, and the mandrel 1 is locked to the wheel seat 8 by the nut 6.

[0044] A retaining ring 2 is provided between the mandrel 1 and the bearing 3 and between the nut 6 and the bearing 3 .

[0045] The front part 82 of the wheel seat 8 and the cutter bar 4 form an angle β, and the axis of the mandrel 1 is perpendicular to the longer side of the cutter bar 4 .

[0046] Th...

Embodiment 3

[0053] The product to be produced is the top of a cylindrical container, which is a super-large thin-walled spherical surface with a diameter of more than 5 meters and a wall thickness of 3mm. Do. After analysis, the large thin-walled curved surface is realized by spinning on a lathe.

[0054] The rough aluminum plate needs to be fixed on the equal-diameter ring flange tooling with a certain strength. The tooling plays the role of fixing and supporting, which is convenient for downward spinning. The support tooling is designed in the shape of a ring, the material is Q235, the diameter is 5 meters, the width of the ring is 135mm, and the height is 100mm. The threaded holes are evenly distributed on the circle, so as to fasten and compress the blank aluminum plate evenly and evenly, and avoid spinning and stretching the edge. Stretch deformation and wrinkles occur.

[0055] In order to ensure good performance, 45 quenched and tempered steel is used to make the clamping handle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com