Balance control circuit for heavy-duty dual-function press beam balance with both return and loading functions

A balanced control and dual-function technology, applied to the driving device of forging presses, etc., can solve problems such as low utilization rate, inability to meet the high-speed requirements of moving beams, and single function, so as to reduce design and manufacturing costs, save costs, and simplify hydraulic systems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

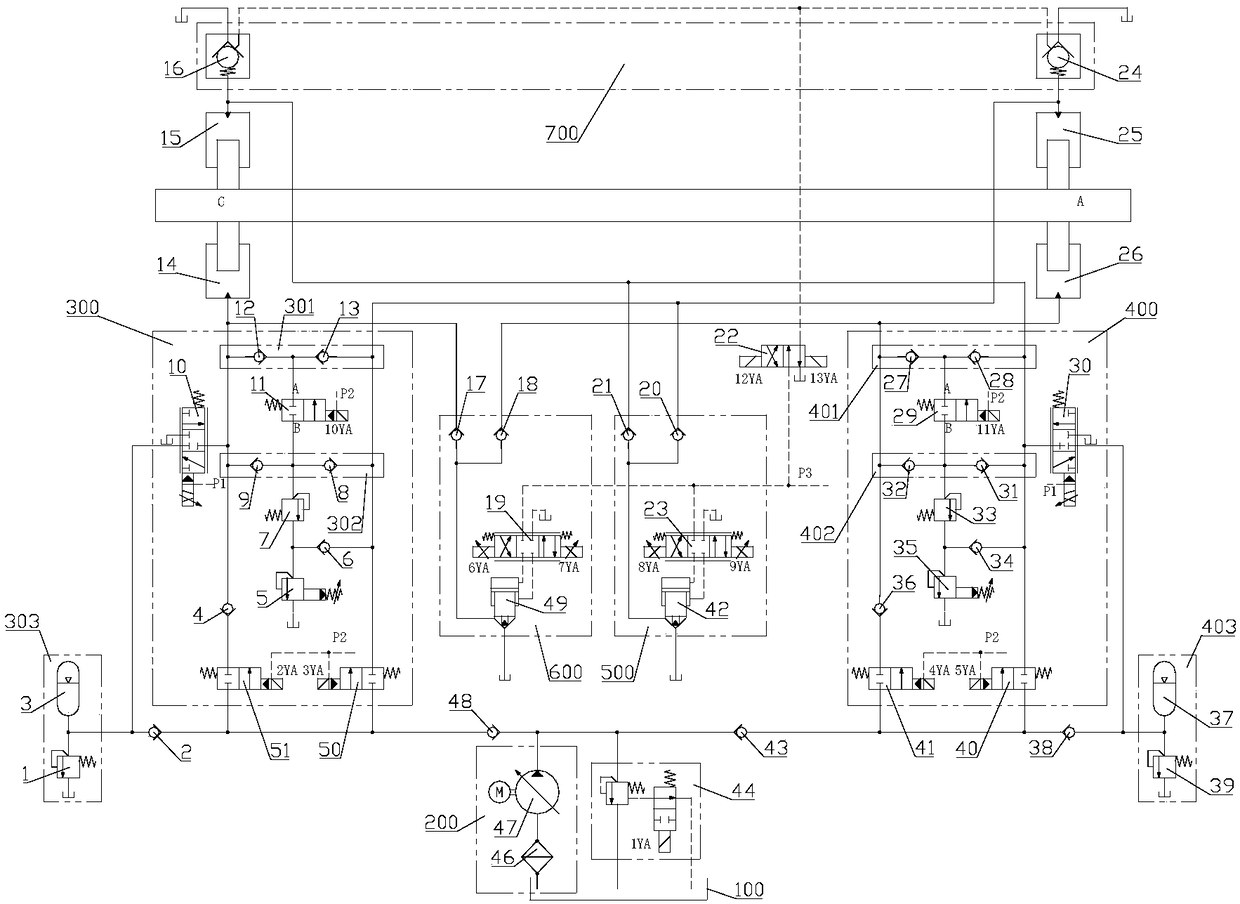

[0020] see figure 1 As shown, the present invention provides a heavy-duty dual-function compressor beam balance control circuit with functions of both return and loading, including a fuel tank 100, a variable pump oil supply sub-circuit 200, a left oil-inlet control sub-circuit 300, a right-input oil control The sub-circuit 400 , the upper balancing cylinder unloading sub-circuit 500 , the lower balancing cylinder unloading sub-circuit 600 , the upper balancing cylinder 15 and the lower balancing cylinder 14 .

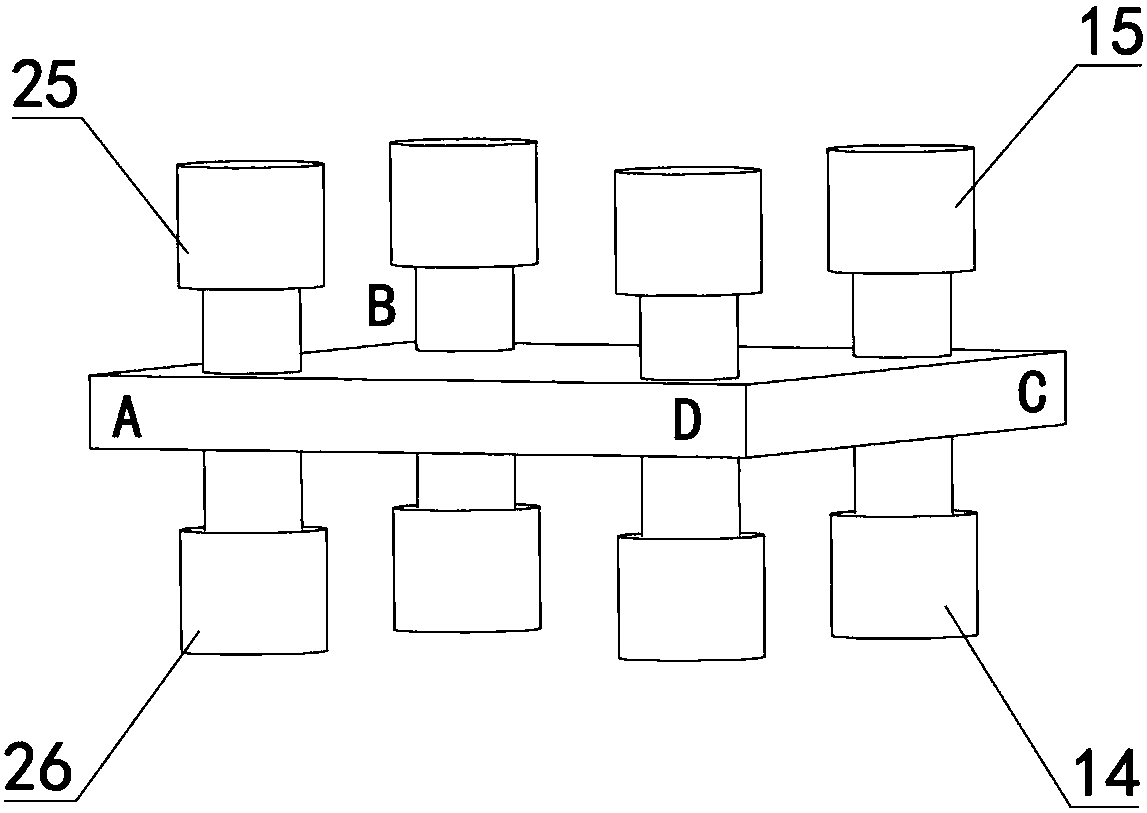

[0021] Wherein, the upper balancing cylinder 15 is installed on the upper surface of the moving beam, and the lower balancing cylinder 14 is installed on the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com