Servo connection rod spraying machine

A sprayer and connecting rod technology, which is applied in the field of sprayers, can solve the problems of affecting the effect of spraying release agent, difficulty in ensuring product quality, poor working stability, etc., and achieves easy installation and daily maintenance, which is conducive to widespread application and lightens the load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

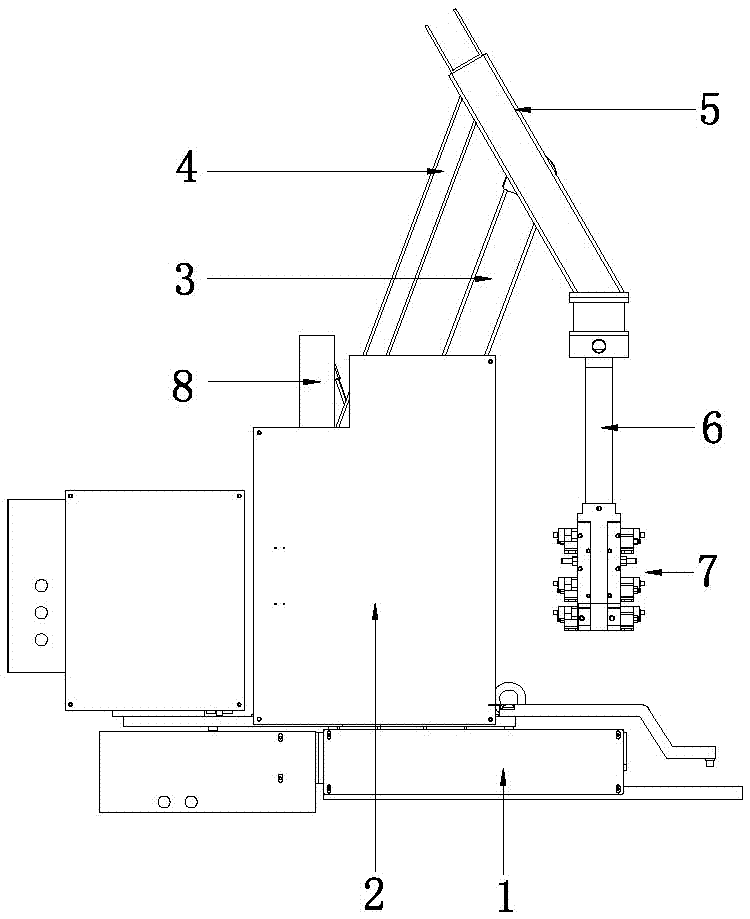

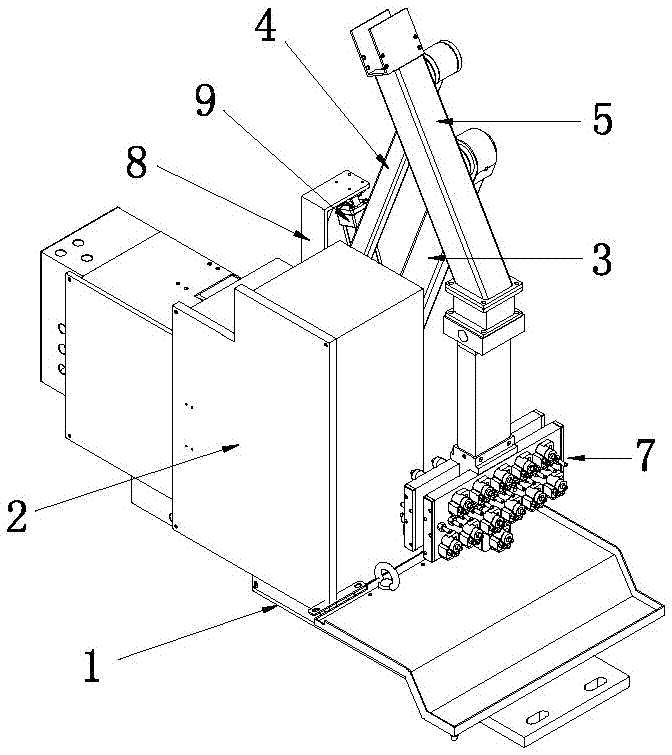

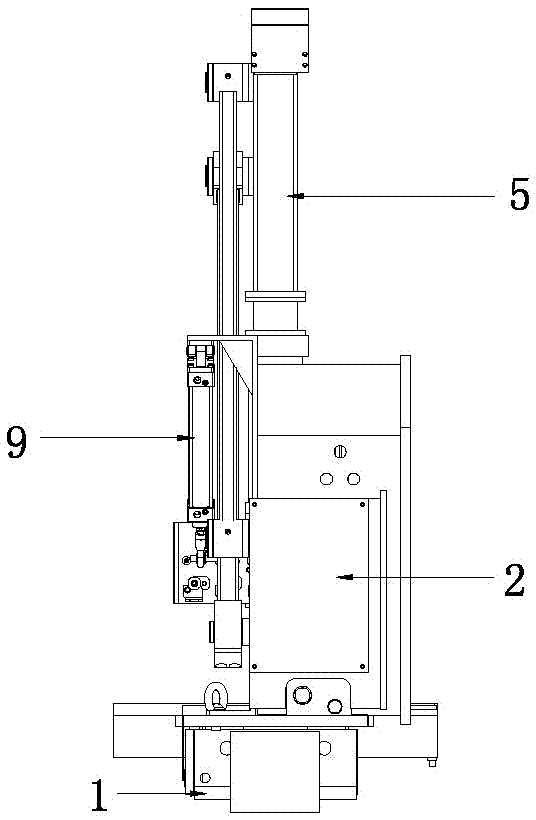

[0021] Examples, see Figure 1 to Figure 6 , a servo connecting rod sprayer provided in this embodiment, which includes a driving slide 1, a worm and gear rotating mechanism 2, a driving connecting rod 3, a driven connecting rod 4, a spray arm 5, a connecting pipe 6 and a spraying module 7 , the worm gear rotating mechanism 2 is arranged on the driving slide 1, one end of the active connecting rod 3 is arranged on the output shaft of the worm gear rotating mechanism 2, and the other end is hinged at the middle part of the spray arm 5, and the slave One end of the moving link 4 is hinged on one end of the spray arm 5, and the other end is hinged on the drive slide 1 corresponding to the position of the active link 3, and the upper end of the connecting pipe 6 is connected with the other end of the spray arm 5, so The spray module 7 is arranged at the lower end of the connecting pipe 6. The spray module 7 includes a connecting head seat 71 and two nozzle fixing plates 72. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com