Laser cladding device with adjustable cladding track and method for adjusting width of cladding track

A laser cladding and cladding technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unstable cladding track height and cross-sectional shape, unfavorable cladding head layout heat dissipation device, etc., to solve the problem of laser cladding The power is limited, the effect of ensuring the cladding effect, and the effect of improving the cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

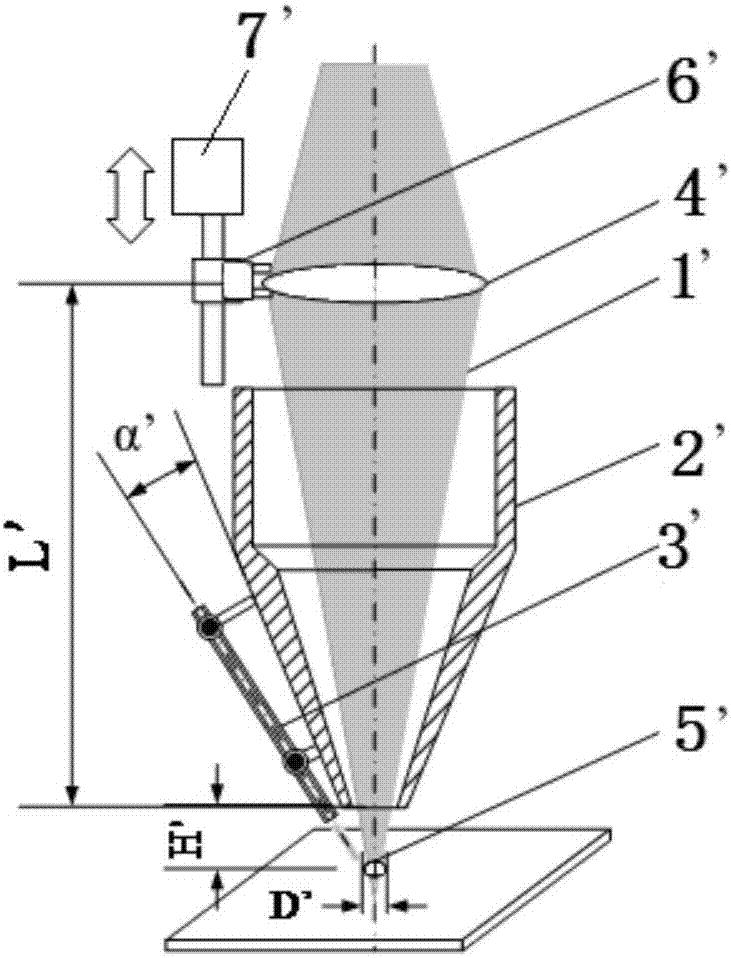

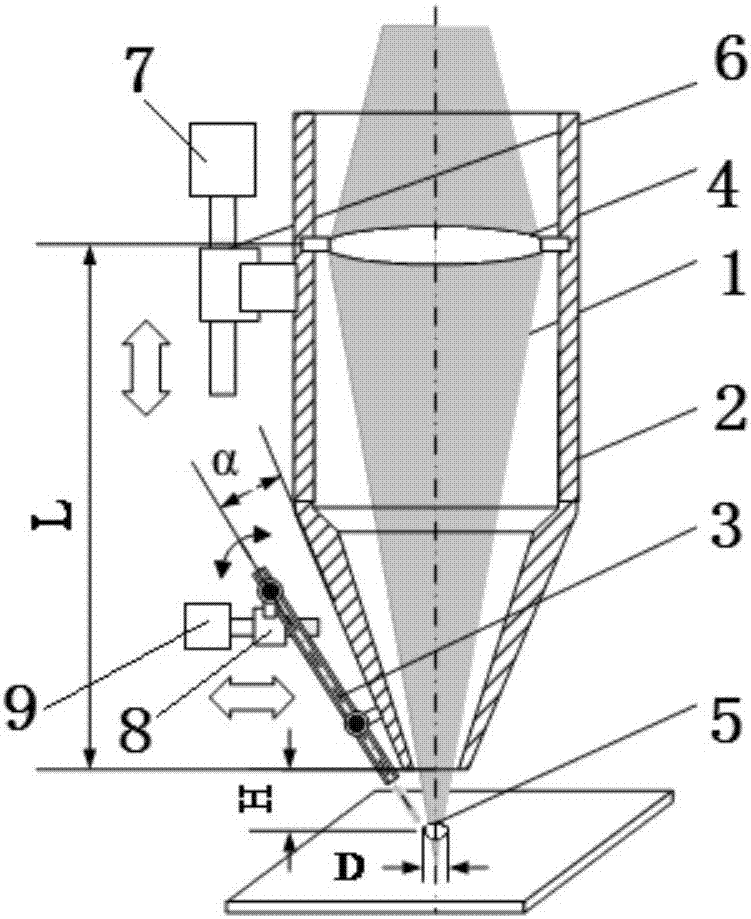

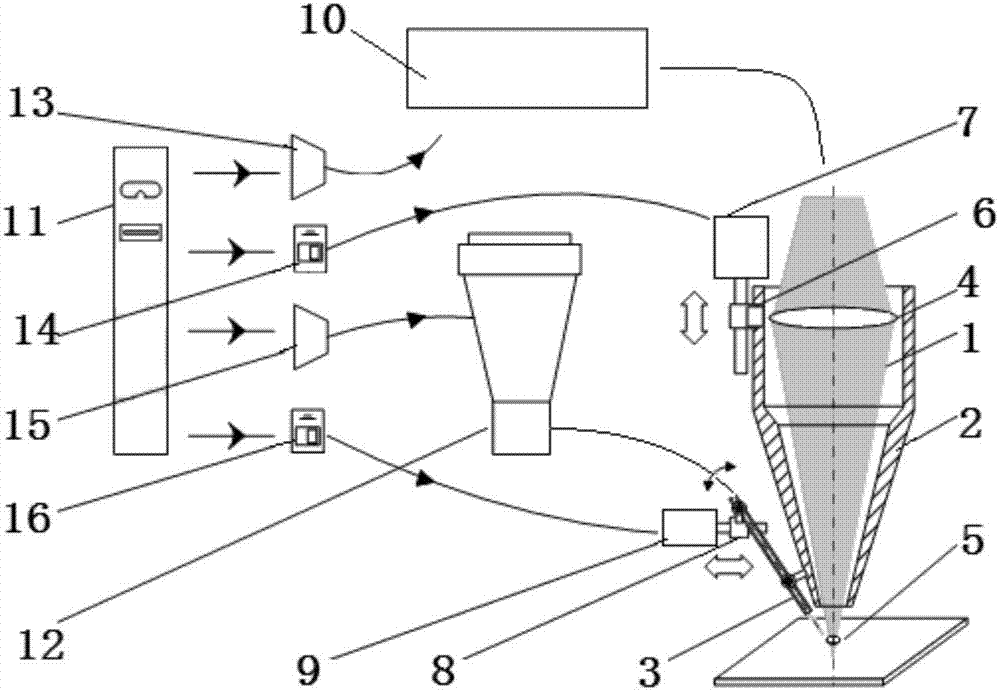

[0030] Referring to the accompanying drawings, the laser cladding device with adjustable cladding trajectory includes a laser cladding head component, a laser 10, a powder feeder 12 and a central controller 11, and both the laser 10 and the powder feeder 12 are connected to the laser cladding head component , the laser cladding head component, the laser 10 and the powder feeder 12 are all connected to the central controller 11;

[0031] The laser cladding head component includes a cladding head 2, the cladding head 2 is installed on a vertical adjustment device that can drive the cladding head 2 to move up and down in the vertical direction, and the cladding head 2 moves vertically A laser inlet is provided above the cladding head, and a laser outlet is provided below the cladding head 2 along the vertical direction; a lens 4 is provided in the cladding head 2, and the lens 4 is coaxially arranged with the cladding head 2;

[0032] The cladding head 2 is provided with a powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com