Automatic assembling production line of electromagnetic door lock

An automatic assembly and production line technology, applied to assembly machines, metal processing equipment, manufacturing tools, etc., to achieve high assembly efficiency, good quality consistency, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

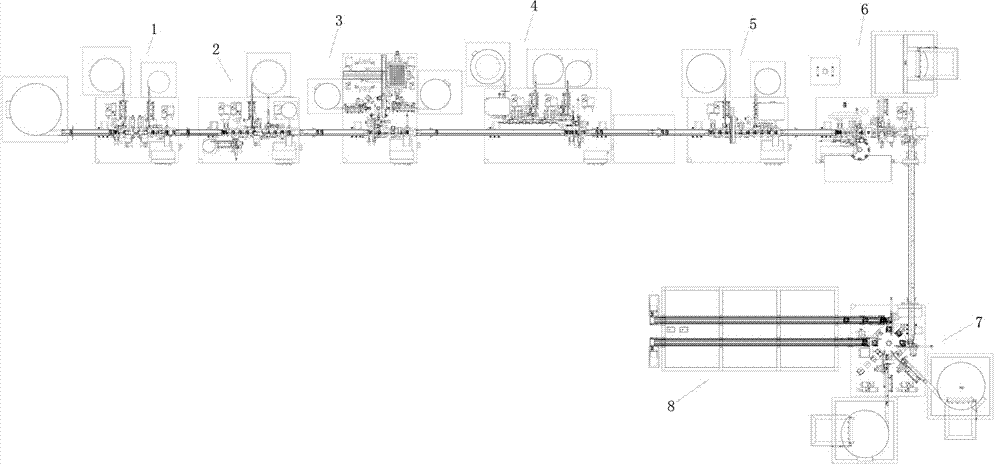

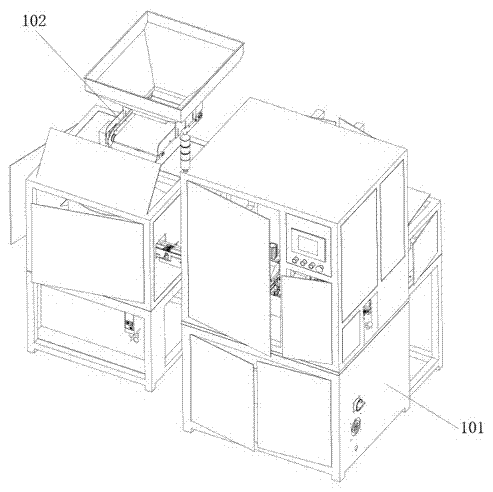

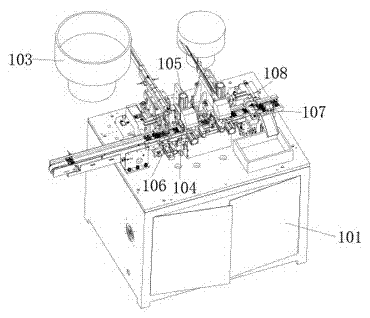

[0044] Such as Figure 1-23 As shown, the present invention includes a terminal assembly mechanism 1, a PTC assembly mechanism 2, an electromagnetic component assembly mechanism 3, a pop-up component assembly mechanism 4, a sliding door frame latch assembly mechanism 5, a shrapnel cover plate assembly mechanism 6, a combined assembly mechanism 7, and manual assembly workbench8.

[0045] The output end of the feeding guide rail 104 of the terminal assembly mechanism 1 is aligned with the feeding end of the feeding guide rail 203 of the PTC assembly mechanism 2, and the two are connected and matched by a feeding belt; the discharge end of the feeding guide rail 203 of the PTC assembly mechanism 2 One end is in alignment with the feeding end of the feeding guide rail 302 of the electromagnetic component assembly mechanism 3, and the two are connected and matched by a feeding belt; The feeding end of the feeding guide rail 402 is aligned and connected, and the two are connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com