Assembling and disassembling mechanism and method for character block for steel rail printer

A character block technology for printers, applied in printing, stamping and other directions, can solve the problems of inaccurate positioning of character blocks, waste of time, high labor intensity, etc., to improve work reliability and work efficiency, high promotion value, labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment and accompanying drawing, the present invention is described in further detail. It should be understood that this embodiment is only used to illustrate the present invention, but not to limit the protection scope of the present invention.

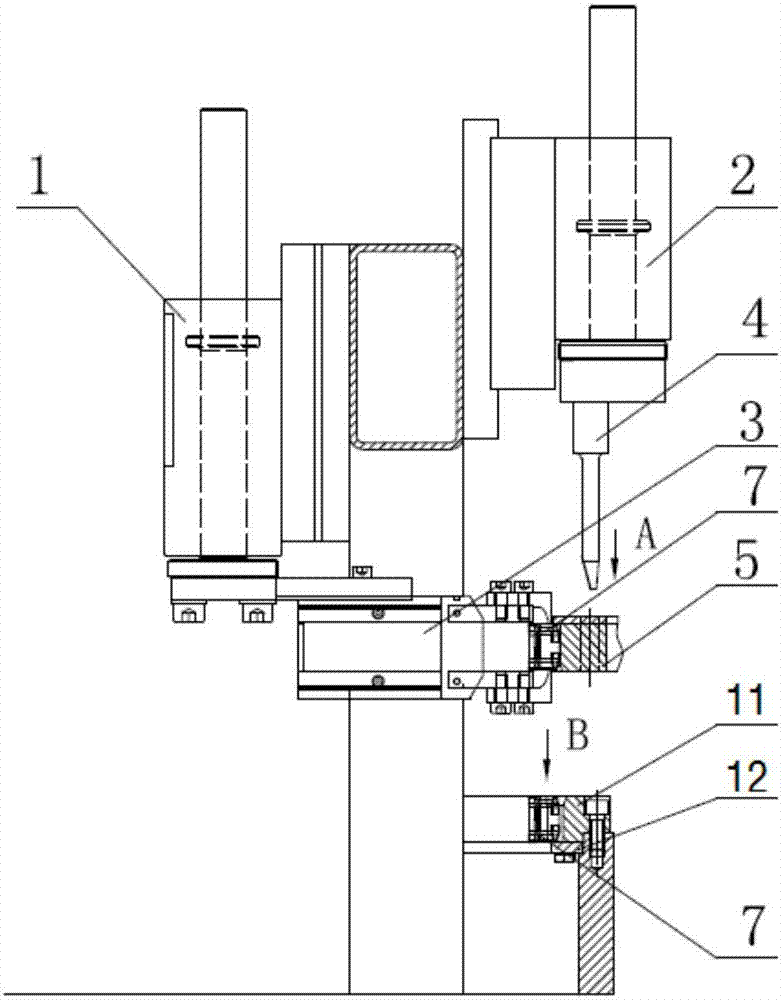

[0027] A character block assembly and disassembly mechanism for a rail printer, wherein:

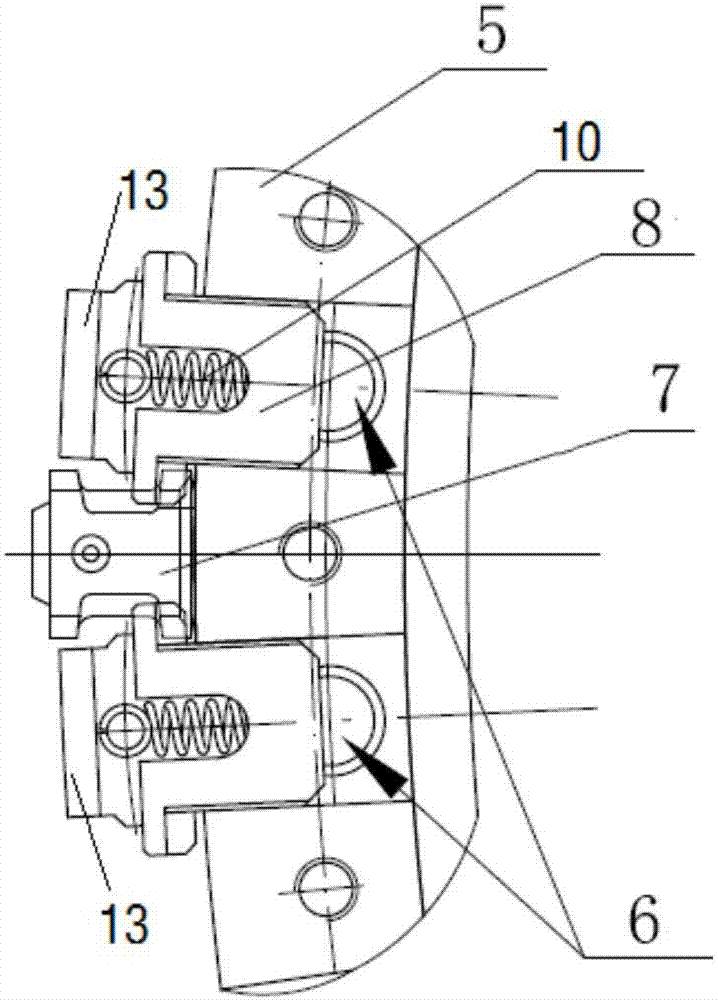

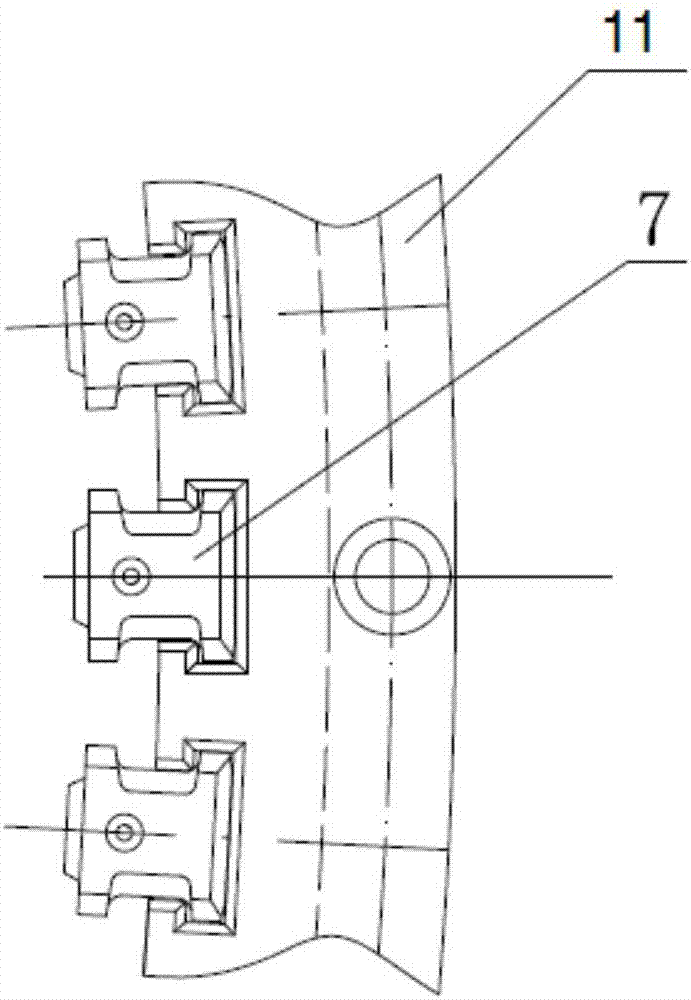

[0028] A character block 7 is installed in the middle of the printing disk 5, and a T-shaped positioning block 8 is clamped on both sides of the character block 7, and a positioning groove 71 is provided on both sides of the character block 7, and the two sides of the positioning groove 71 are pressed. The convex edge 72, the two sides of the T-shaped positioning block 8 are provided with a limiting boss 81 matching the positioning groove 71, and the two sides of the limiting boss 81 are pressing surfaces 82;

[0029] The printing disc 5 is also provided with a fixed cover 13, one end of the reset compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com