Uniform speed symmetrical uniaxial tension cell mechanical device for real-time in-situ observation

A uniaxial stretching and symmetric technology, applied in the fields of mechanobiology and biomechanics, can solve the problems of narrow adjustable range, dependence on stretching length, and non-uniform stretching speed, achieving wide adjustable range and simple mechanism structure. Compact, smooth transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

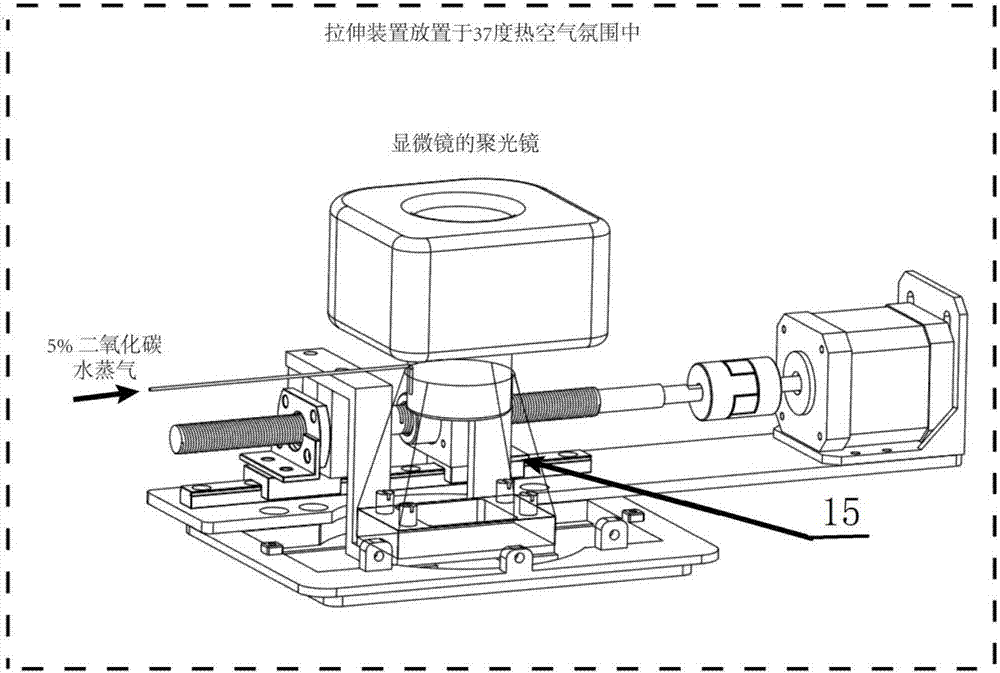

[0018] This embodiment provides a uniform-velocity symmetrical uniaxial substrate stretching cell mechanical loading device that can be installed on a microscope stage for real-time on-site long-term observation.

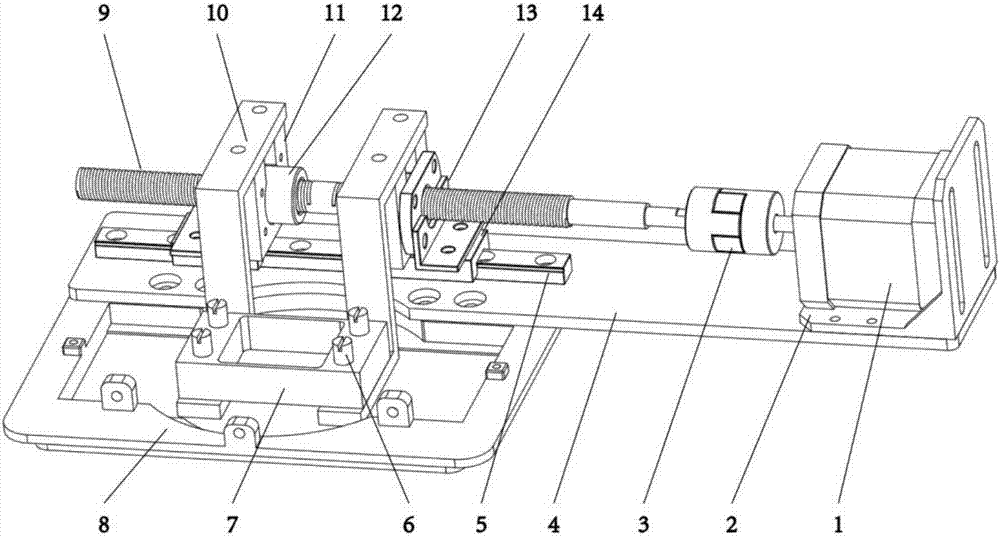

[0019] Such as figure 1 As shown, the mechanical loading device includes: a power unit, a motion execution unit, a transparent stretching vessel 7, a clamping platform 8 and a flexible and expandable airbag. The power unit includes a stepper motor 1 and its controller, driver, motor coupling 3 and motor bracket 2; the motion execution unit includes: two sliders 14, linear slide rails 5, two-way lead screw 9, nut seat 12 , the stretching arm 10, the stretching arm fixing seat 11 and the nut slider connector 13.

[0020] The connection relationship is as follows: the stepping motor 1 is installed on the motor support 2, and the motor support 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com