A high-damping rubber cylinder segmented damper with shape-memory alloy wire wrapped around it

A memory alloy wire and cylinder technology, which is used in protective buildings/shelters, bridge parts, bridges, etc., can solve the problems of low rigidity and insignificant energy consumption effect of high-damping rubber shock absorbers, and can achieve stable rigidity. Adjustment, easy real-time monitoring, improve the effect of poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment describe the present invention in detail:

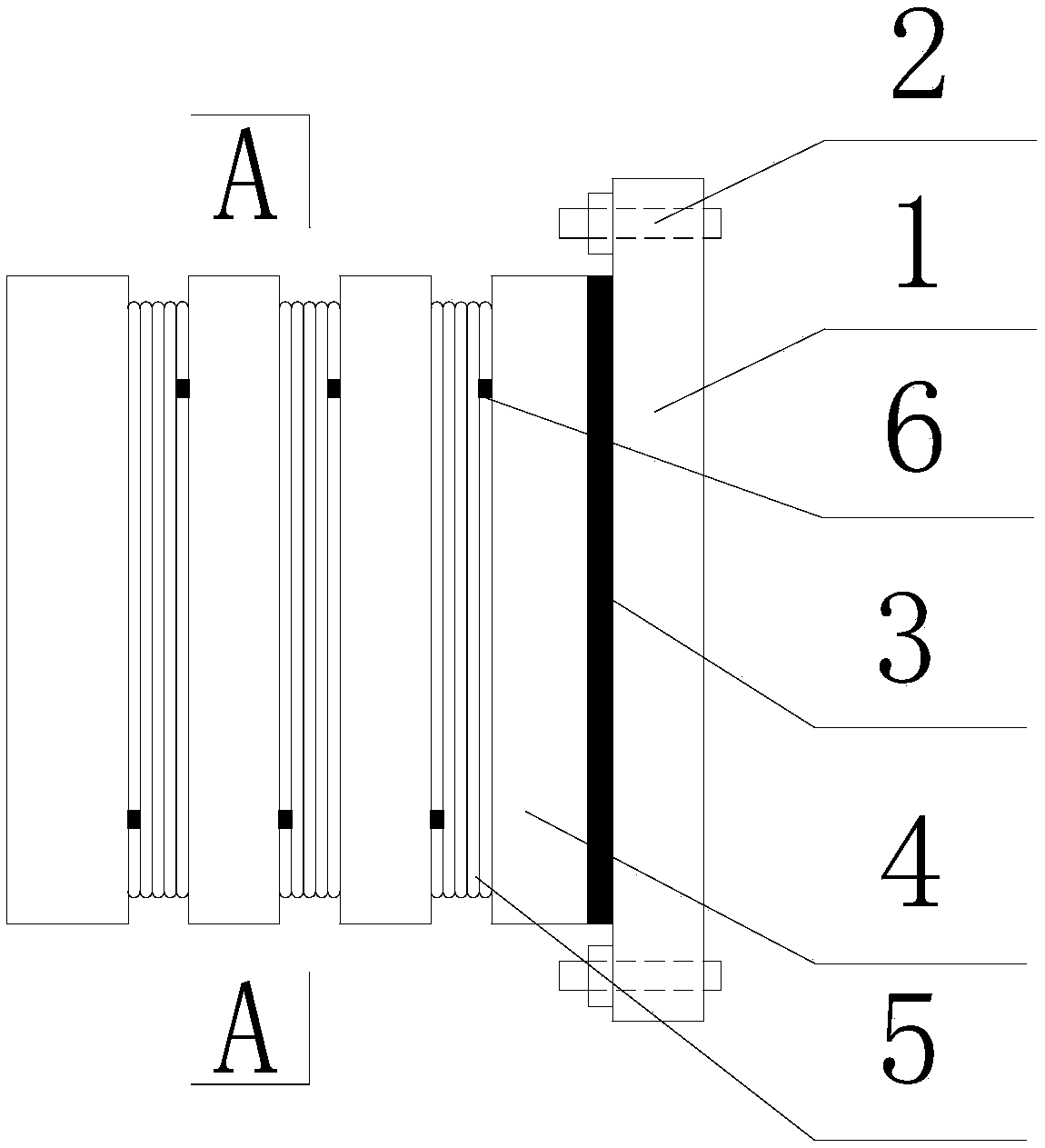

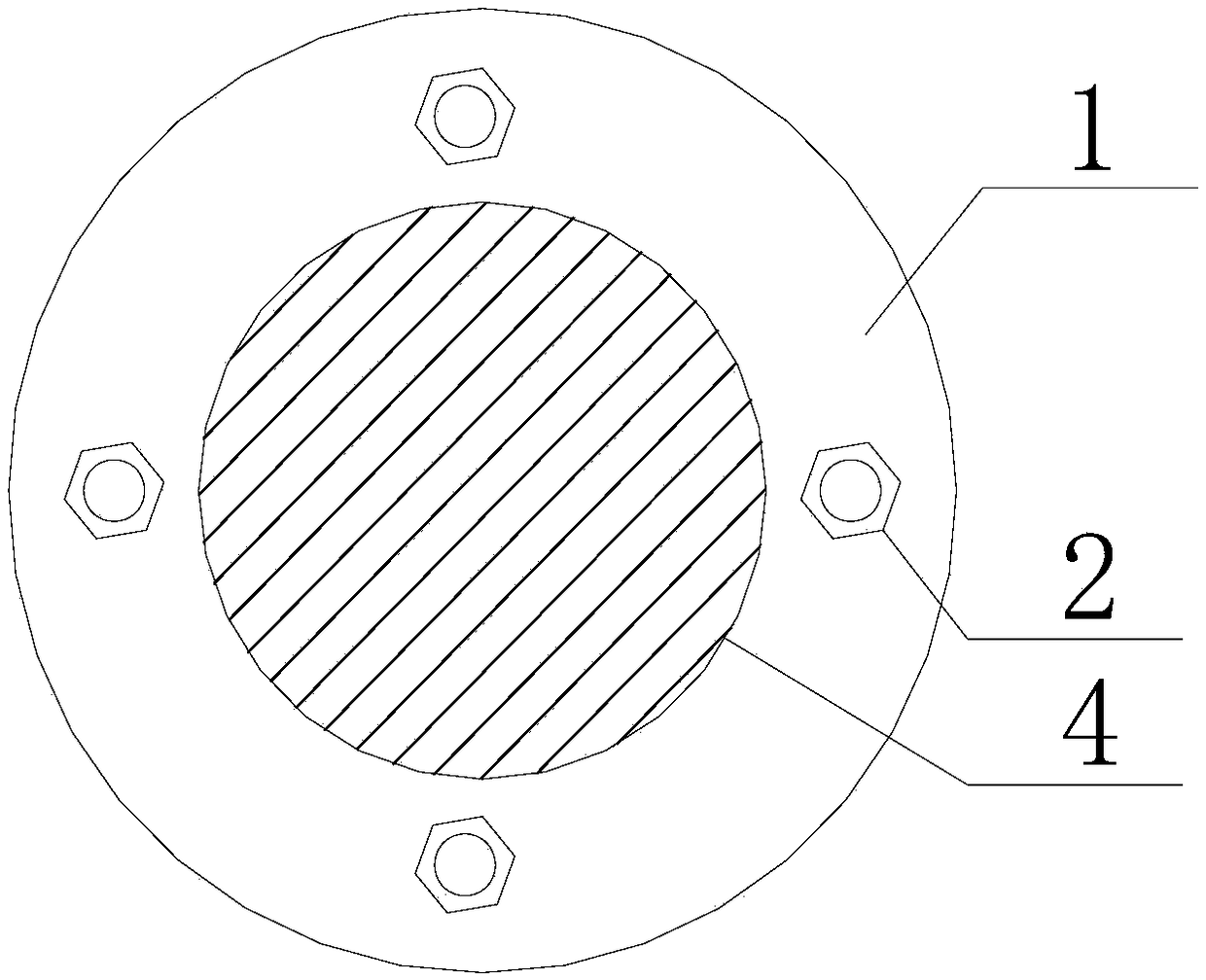

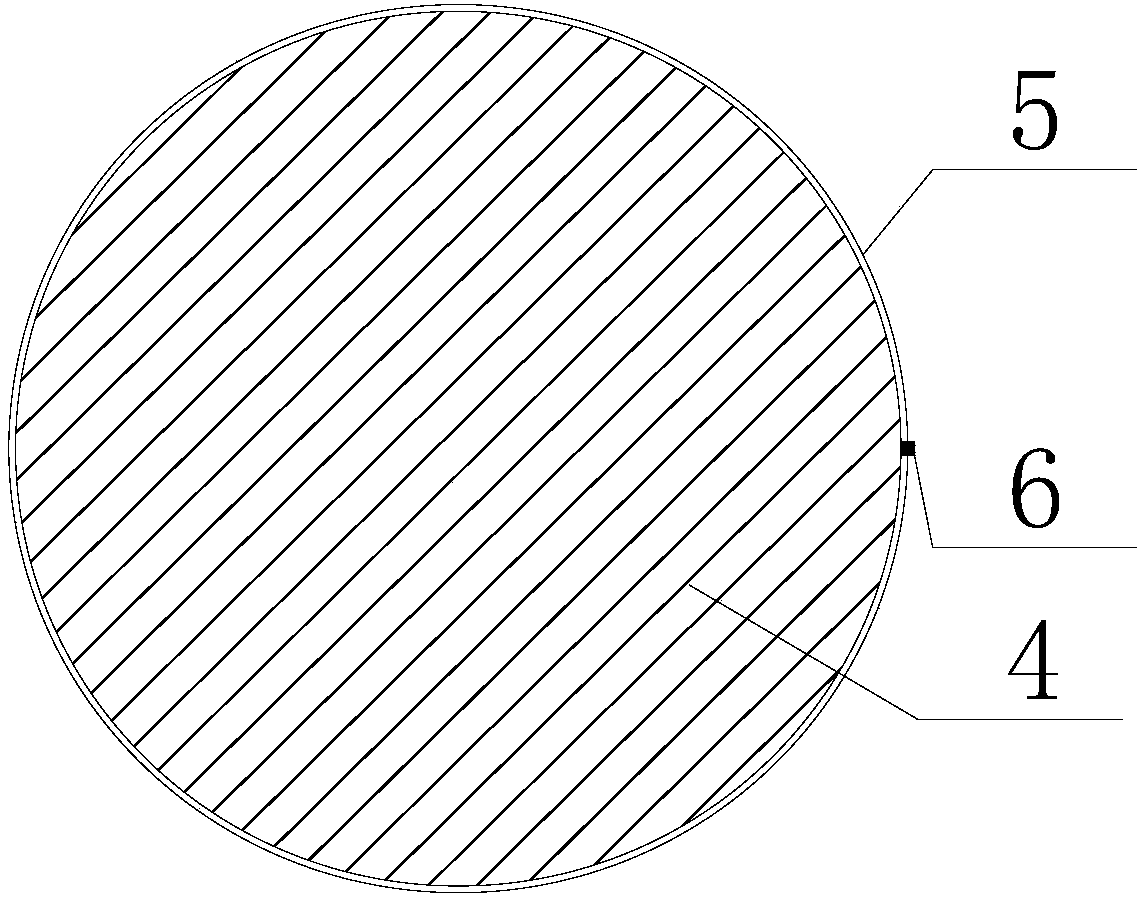

[0032] A high-damping rubber cylinder segmented damper wrapped with shape-memory alloy wires, such as figure 1 As shown, it includes a connecting steel plate 1, a connecting bolt 2, a cementation layer 3, a high damping rubber cylinder 4, a shape memory alloy wire 5, and an anchoring device 6;

[0033] Such as Figure 1-4 As shown, the connecting steel plate 1 is circular, and bolt holes 7 are reserved, one side is consolidated with the high damping rubber cylinder 4 through the cement layer 3, and the other side is installed on the On one of the structures, such as bridge piers or blocks;

[0034] Such as Figure 1-3 with Figure 5 As shown, the side of the high damping rubber cylinder 4 has grooves at a certain distance, one end is consolidated with the connecting steel plate 1 through the cement layer 3, and the other end is free; the shape is wound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com