Structural steel-steel car combined structure, manufacturing method and structural steel concrete structure

A technology of concrete structure and composite structure, which is applied in the direction of building structure and construction, and can solve the problems of difficult construction, more holes in the web of section steel, and affecting the overall strength of section steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

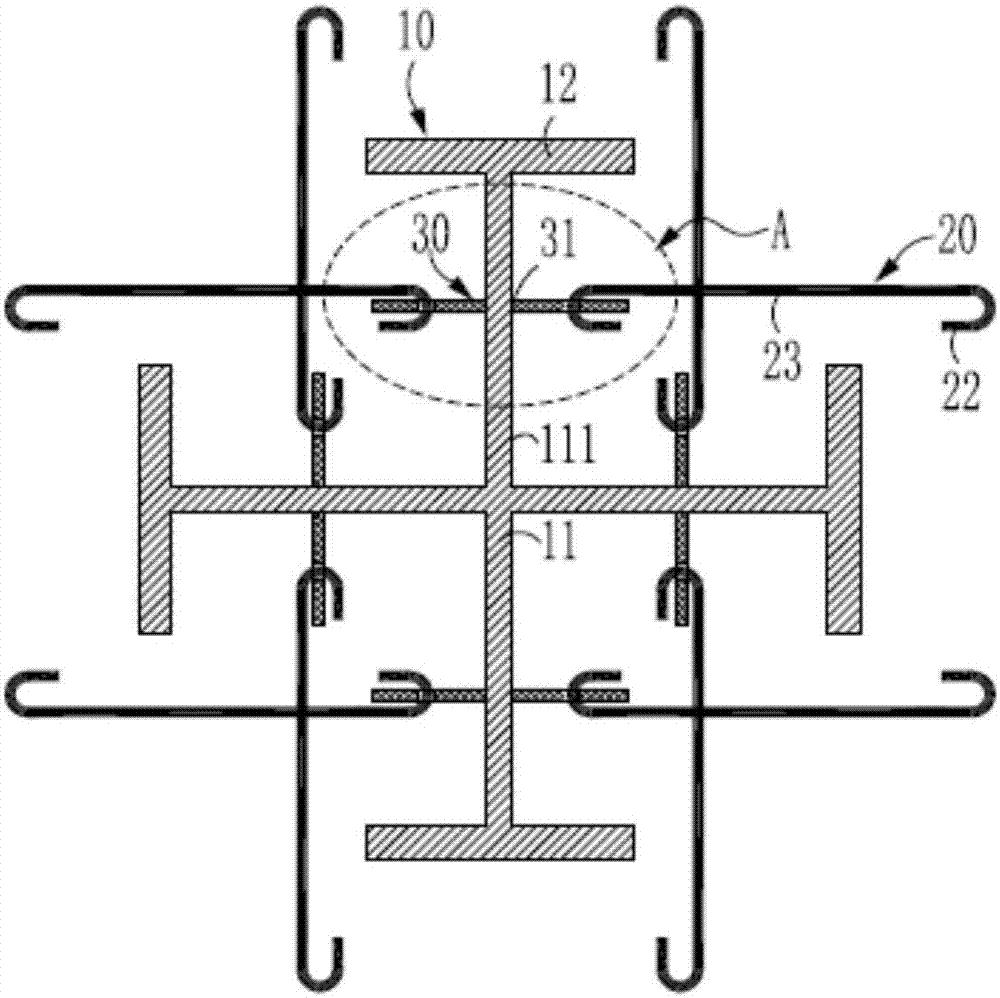

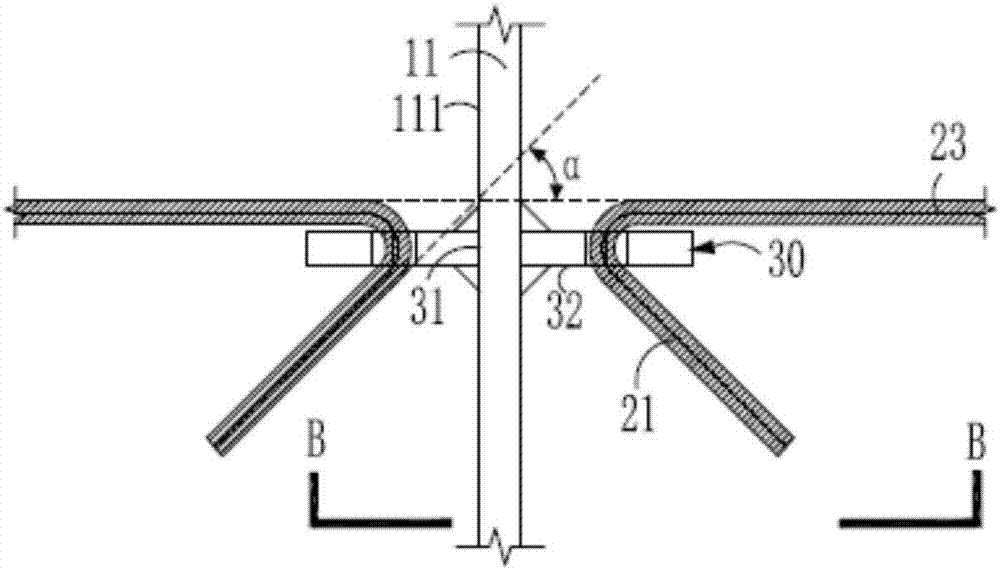

[0101] This embodiment provides a composite structure of section steel-reinforcing bar, such as figure 2 , image 3 As shown, it includes section steel 10, several tie bars 20 and several connecting pieces. Wherein, the shaped steel 10 includes a web 11 , and flange plates 12 located at both ends of the web 11 and perpendicular to the web 11 . One side of the connector is fixedly connected to the web 11 , the first end 21 of the tie bar 20 is fixedly connected to the connector, and the second end 22 opposite to the first end 21 is a free end. In this embodiment, the connecting piece is fixed on the web of the shaped steel 10, so that the tie bars can be directly connected with the connecting piece, instead of passing through the web after perforating the web. This can avoid opening holes on the web plate due to the setting of tie bars, avoid reducing the overall strength of the section steel, and secondly make the opening operation easier for construction, improve construct...

Embodiment 2

[0115] This embodiment provides a composite structure of section steel-reinforcing bar, such as Image 6 , Figure 7 As shown, it includes section steel 10, several tie bars 20 and several connecting pieces. Wherein, the shaped steel 10 includes a web 11 , and flange plates 12 located at both ends of the web 11 and perpendicular to the web 11 . One side of the connector is fixedly connected to the web 11 , the first end 21 of the tie bar 20 is fixedly connected to the connector, and the second end 22 opposite to the first end 21 is a free end. In this embodiment, the connecting piece is fixed on the web of the shaped steel 10, so that the tie bars can be directly connected with the connecting piece, instead of passing through the web after perforating the web. This can avoid opening holes on the web plate due to the setting of tie bars, avoid reducing the overall strength of the section steel, and secondly make the opening operation easier for construction, improve construct...

Embodiment 3

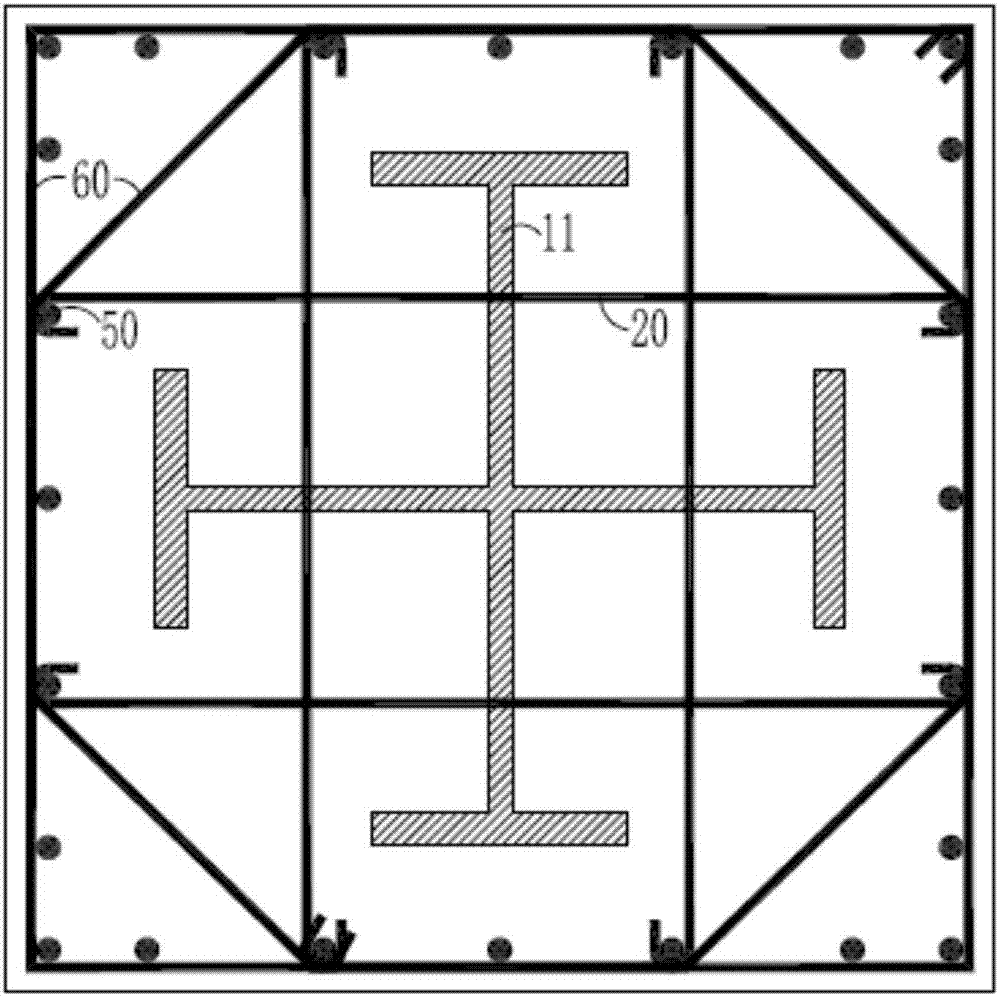

[0127] This embodiment provides a steel concrete structure, such as Figure 11 to Figure 13 As shown, it includes section steel 10, some tie bars 20, some connectors, some longitudinal bars 50, some stirrups 60 and concrete 70, wherein:

[0128] Shaped steel 10 is a cross-shaped steel, including web 11 and flange plate 12, and this flange plate 12 is positioned at the two ends of web 11 and intersects perpendicularly with web 11; Figure 11 The direction perpendicular to the paper surface) is arranged around the section steel, and the longitudinal bars 50 are arranged at intervals; the stirrups 60 are closed and enclosed outside the longitudinal bars 50 along the direction perpendicular to the length of the longitudinal bars 50, and are fixed to the longitudinal bars 50 Form the outer boundary of the above-mentioned shaped steel concrete structure; one side of the connector is fixedly connected to the plane 111 of the web 11, the first end 21 of the tie bar 20 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com