Hangar door body structure with icing prevention function and manufacturing process thereof

A manufacturing process and anti-icing technology, applied in building structures, doors, windows/doors, etc., can solve the problems of time-consuming, labor-intensive, heavy weight, etc., and achieve the effects of high operability, low cost, and small thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

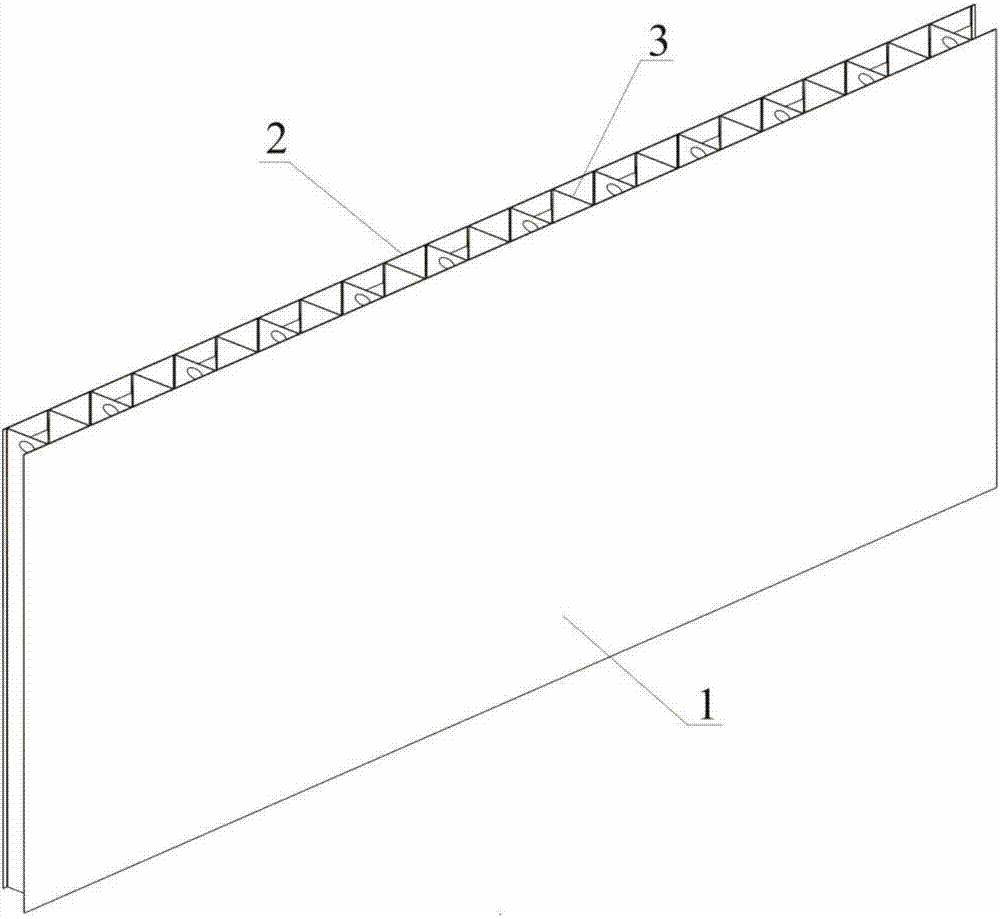

[0060] 1) The flattened 921A special steel plate is cut into outer panel 1 and inner panel 2 of equal thickness by laser cutting technology, and the thickness of the plate is 7.5-9mm;

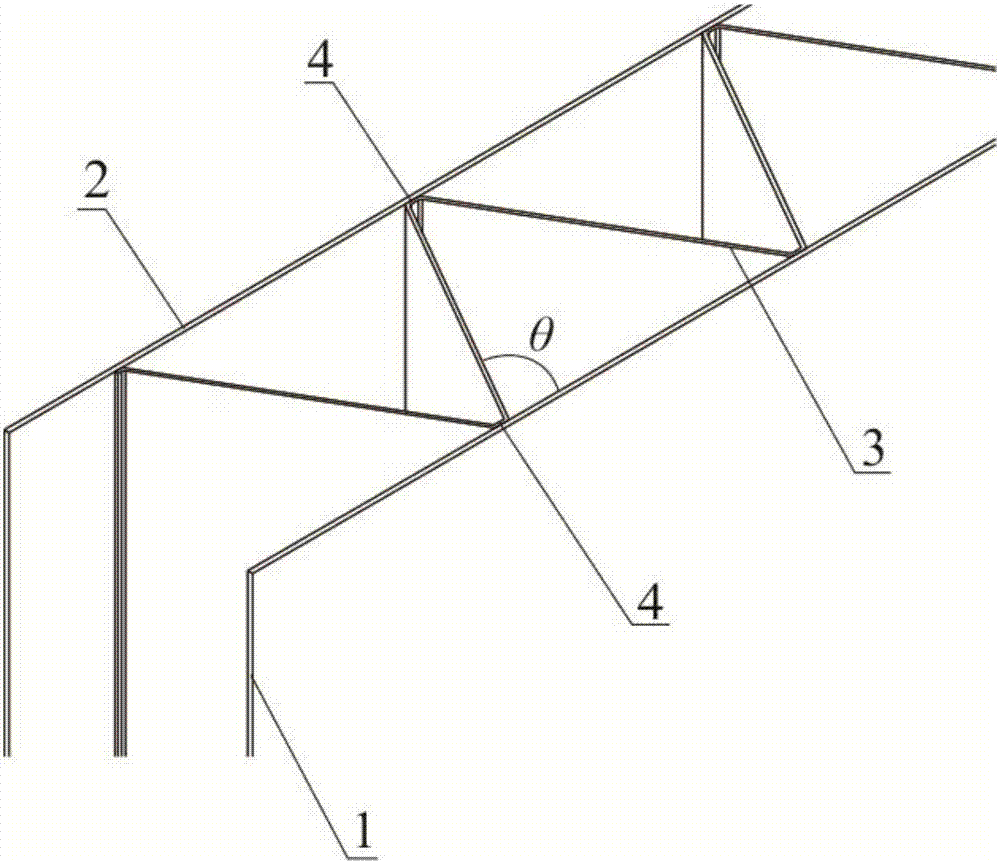

[0061] 2) The flattened 921A special steel sheet is processed by bending technology into figure 1 In the shown corrugated core 3, the inclination angle of the corrugated core is 50°, the width of the corrugated core platform 4 is 20mm, the thickness of the plate is 5-5.5mm, and the centerline height of the corrugated core is 375-385mm;

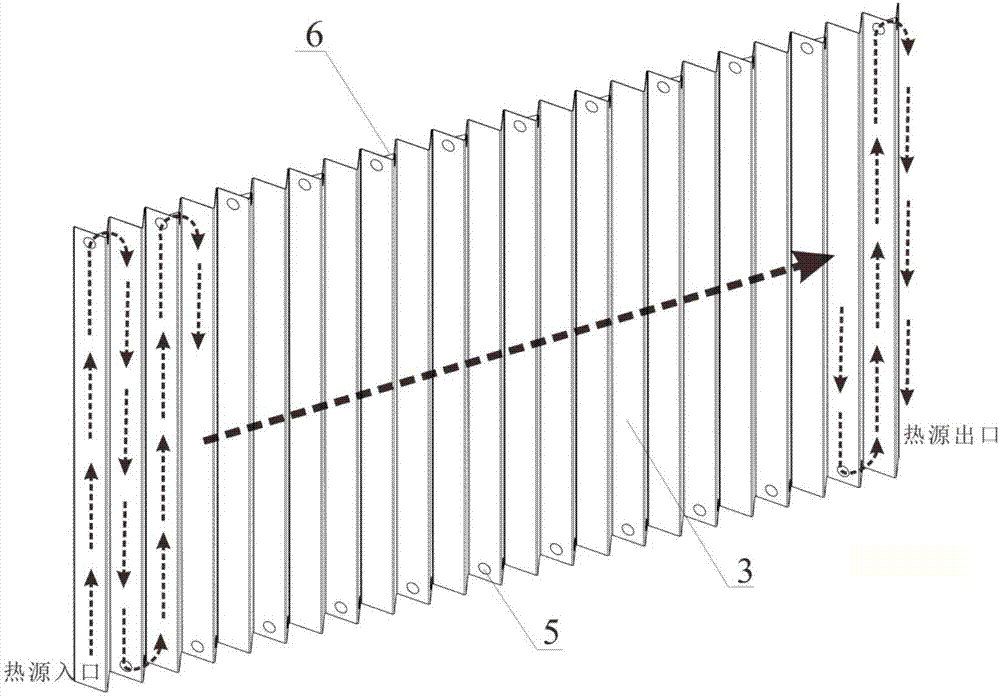

[0062] 3) The air flow hole 5 is processed in the corrugated core 3 according to the designed position by laser cutting technology, and the diameter of the hole is φ140-155mm;

[0063] 4) Assemble the inner panel 2 and the corrugated core 3 according to the designed position, fix them with a fixture, and connect them with a 10,000-watt-level large-scale laser welder. The connection positions are 4 places on the corrugated core platform, and the laser welding se...

Embodiment 2

[0069] 1) The flattened 921A special steel plate is cut into outer panel 1 and inner panel 2 of equal thickness by CNC water jet cutting technology, and the thickness of the plate is 7.5-9mm;

[0070] 2) Laser cutting technology is used to process the hot air flow holes 5 in the corrugated core at equal intervals according to the design position, and the diameter of the holes is φ140-155mm;

[0071] 3) The 921A special steel sheet processed with hot air flow holes 5 is processed by bending technology into figure 1 For the corrugated core 3 shown, the inclination angle of the corrugated core is 60°, the width of the corrugated core platform 4 is 25 mm, the thickness of the plate is 5-5.5 mm, and the centerline height of the corrugated core is 375-385 mm;

[0072] 4) Assemble the inner panel 2 and the corrugated core 3 according to the designed position, fix them with a fixture, and connect them with a 10,000-watt-level large-scale laser welder. The connection positions are 4 pl...

Embodiment 3

[0078] 1) The flattened titanium alloy sheet is cut into outer panel 1 and inner panel 2 of equal thickness by CNC water jet cutting technology, and the thickness of the sheet is 7.5-9mm;

[0079] 2) The flattened titanium alloy plate is processed into figure 1 In the shown corrugated core 3, the inclination angle of the corrugated core is 50°, the width of the corrugated core platform 4 is 20mm, the thickness of the plate is 5-5.5mm, and the centerline height of the corrugated core is 375-385mm;

[0080] 3) Laser cutting technology is used to process the hot air flow hole 5 in the corrugated core body 3 according to the designed position, and the diameter of the hole is φ140-155mm;

[0081] 4) Assemble the inner panel 2 and the corrugated core 3 according to the designed position, fix them with a fixture, and connect them with a 10,000-watt-level large-scale laser welder. The connection positions are 4 places on the corrugated core platform, and the laser welding seams are tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com