Torque self-balancing nested double drill bits

A double-bit, nested technology, which is applied in the field of drilling and drilling, can solve the problems of drill bit cutting tooth avalanche, wellbore expansion, low drilling cost, etc., and achieve the effect of torque balance and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

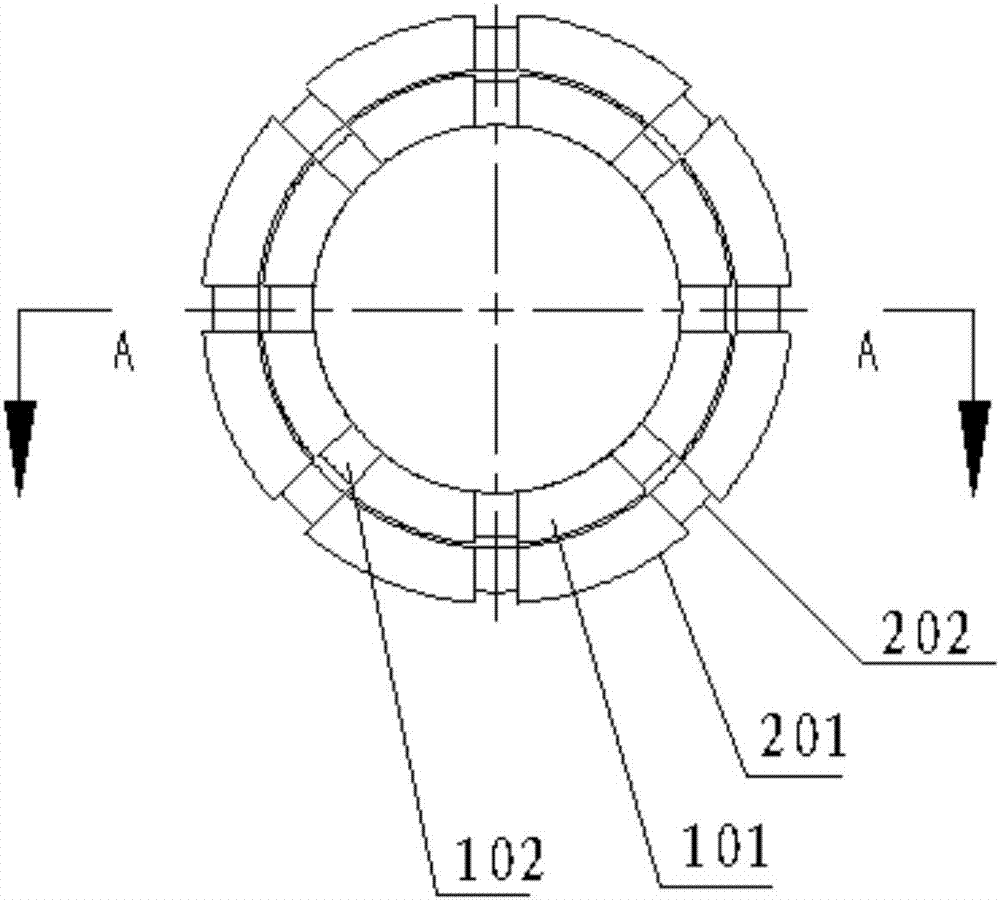

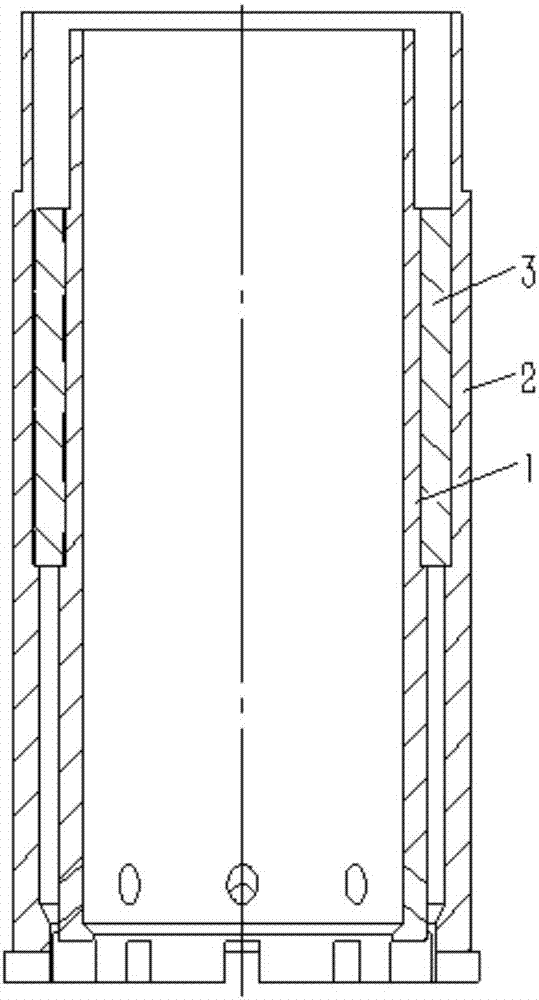

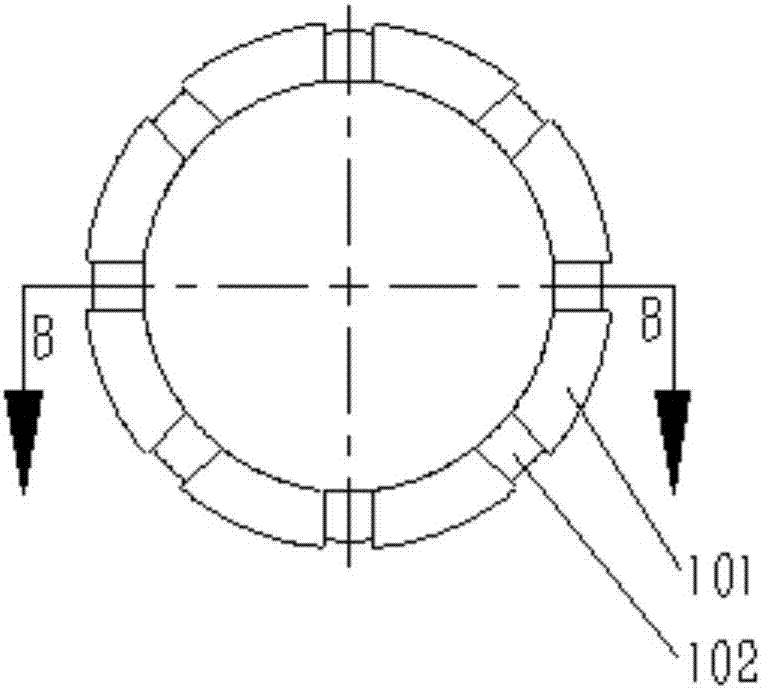

[0029]The present invention proposes a torque self-balancing nested double drill bit, which is composed of an inner drill bit 1, an outer drill bit 2 and a straightening and wear-resistant sleeve 3 for the inner and outer drill bits. The inner drill bit 1 and the outer drill bit 2 act together to break the rock in a relatively balanced state, and are composed of the inner drill bit cutting teeth 101, the inner drill bit nozzle 102, the inner drill bit outer step 103, the inner drill bit rigid body 104 and the jet hole 105. The cutting teeth 101 of the inner bit are diamond-impregnated, mainly crushing formation rocks in the form of grinding; the nozzle 102 of the inner bit is provided with an inner water tank, and no outer water tank is provided; the outer steps 103 of the inner bit are used to limit the downward movement of the inner and outer drill bit straightening wear-resistant sleeves 3; The jet hole 105 is used to prevent and clean up cuttings or rock powder entering bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com