A Method of Reducing the Width of Stopped Coal Pillars in Extra-thick Coal Seams by Combining Masonry and Filling

A technology of ultra-thick coal seam and width, which is applied in the field of masonry and filling combined with reducing the width of coal pillars for stopping mining in extra-thick coal seams, which can solve the problems of very little involvement of extra-thick coal seams, achieve improved coal recovery rate, easy construction, and simple procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

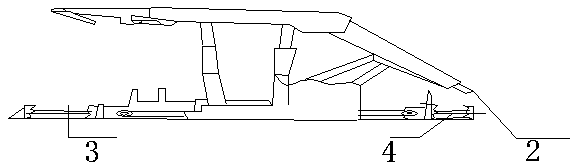

[0034] Schematic diagram of the structure of the low-level coal-loading plate-type double-conveyor is shown in figure 1 , including shovel 2, front scraper conveyor 3, and rear scraper conveyor 4. The working status of the double conveyors in the coal discharge process and the non-coal discharge process is the same, the difference is whether the rear coal discharge shovel is retracted, so as to control whether to collect the top coal.

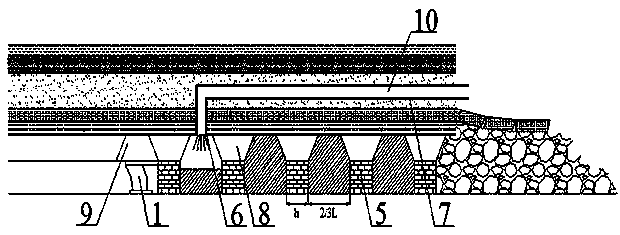

[0035] Taking the Anjialing Coal Mine as an example below, the width of the coal pillars that stop mining in extra-thick coal seams can be reduced through the combination method of laying and filling provided by the present invention, which specifically includes the following steps:

[0036] (1) A working face in Anjialing mines extra-thick coal up to about 14m. First, a roadway parallel to the direction of the working face is opened in the relatively soft siltstone layer about 10m above the extra-thick coal seam, that is, the grouting pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com