A muffler pneumatic valve assembly

A technology of pneumatic valves and mufflers, which is applied in the direction of machines/engines, mufflers, engine components, etc., can solve problems such as single means of control mode, increased reliability risk, and loss of engine performance in some departments, so as to improve reliability and avoid The effect of spring decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

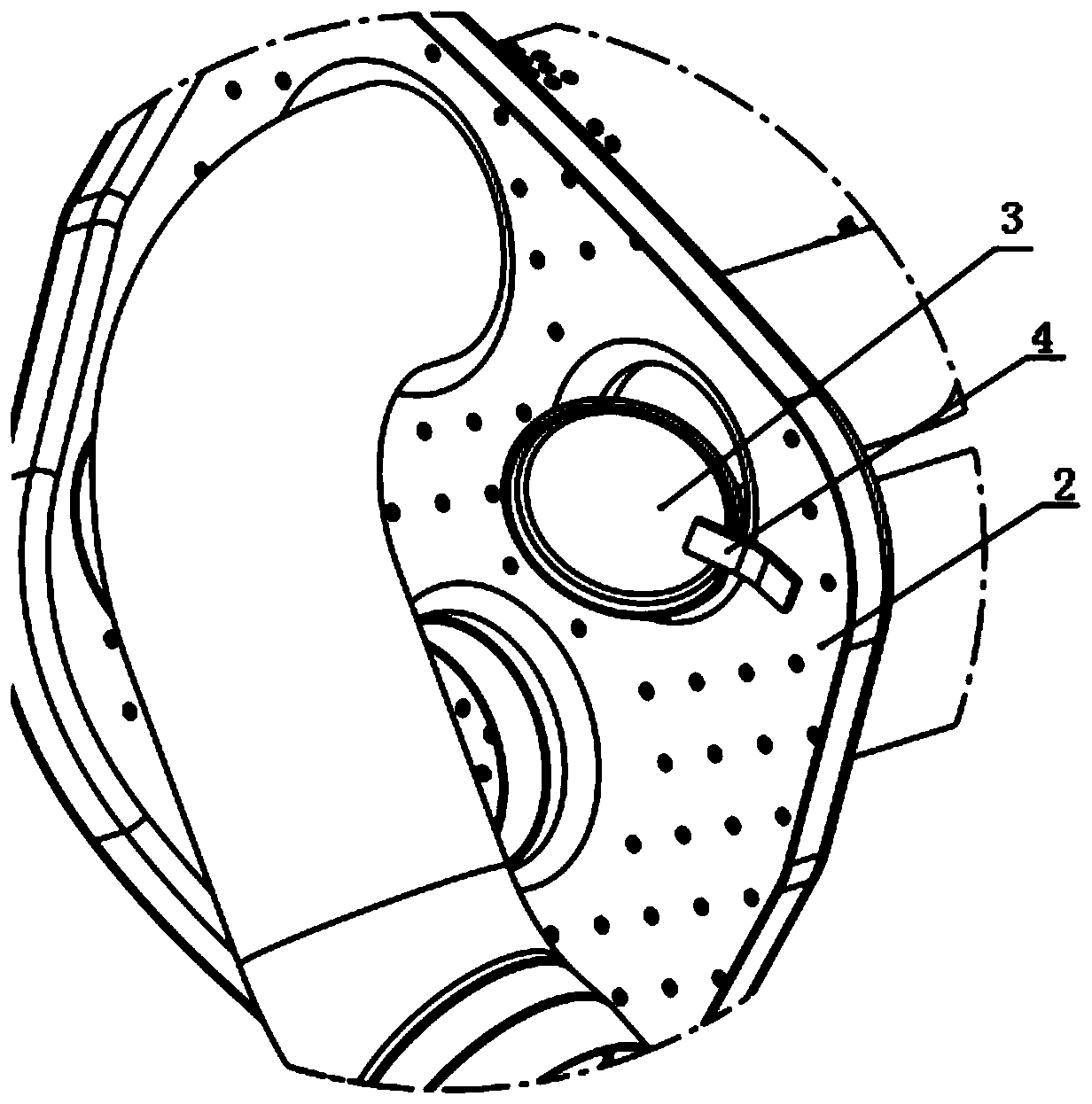

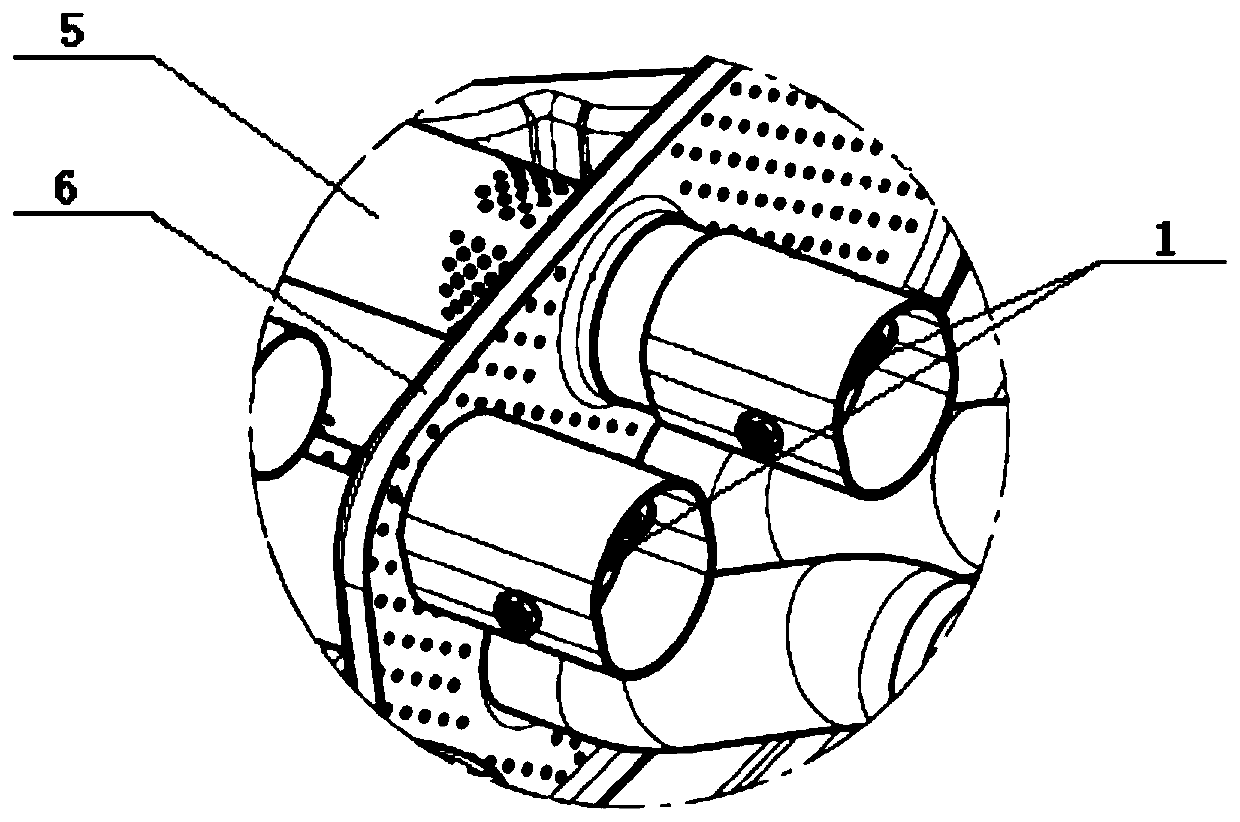

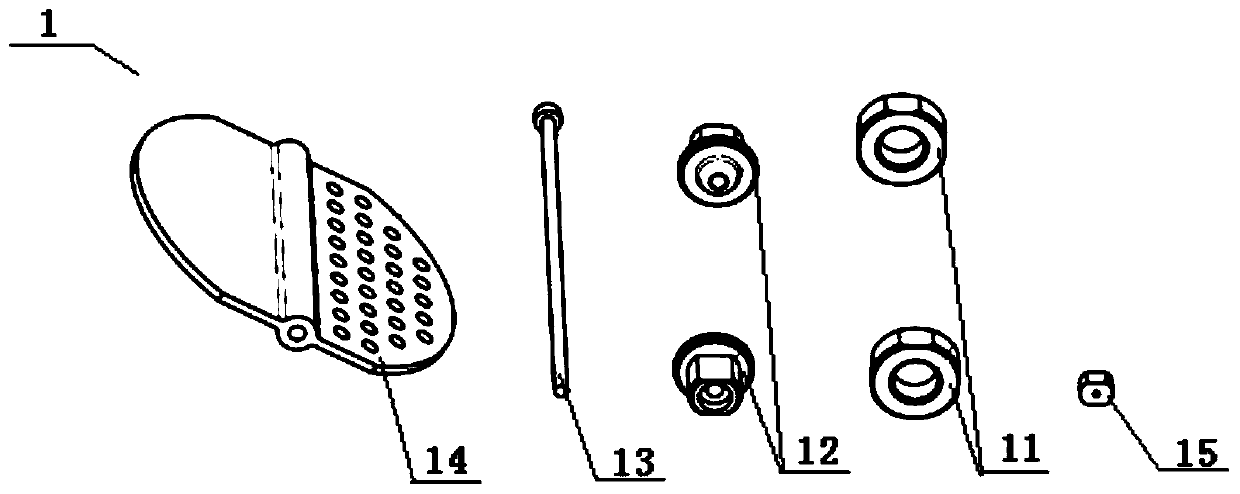

[0028] Such as Figure 2-5 The pneumatic valve assembly of a muffler shown includes a pneumatic valve plate 14, and the middle part of the pneumatic valve plate 14 is provided with a shaft sleeve 141 radially penetrating and integral with it, and the sleeve separates the pneumatic valve plate 14 into left and right Two parts, characterized in that: it also includes a support shaft 13 passing through the sleeve 141 on the pneumatic valve plate 14, a thrust bearing 12 and a limit nut 11 respectively arranged at both ends of the support shaft 13, and a support for fixing the support shaft 13 Shaft fastening nut 15. After the pneumatic valve plate 14 is impacted by the airflow, it will convert part of the kinetic energy of the airflow into the rotational kinetic energy of the pneumatic valve plate 14, so as to achieve the purpose of retarding the airflow fluctuation and reducing noise.

[0029] Such as Figure 6 As shown, both ends of the sleeve 141 extend outward to form sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com