Oil filter capable of controlling pressure fluctuation

A technology of pressure pulsation and oil filtration, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as reduction of natural frequency of pipelines, fretting wear on the surface of supporting structures, fluid-solid coupling vibration, etc. , to suppress pressure pulsation, maintain cleanliness, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

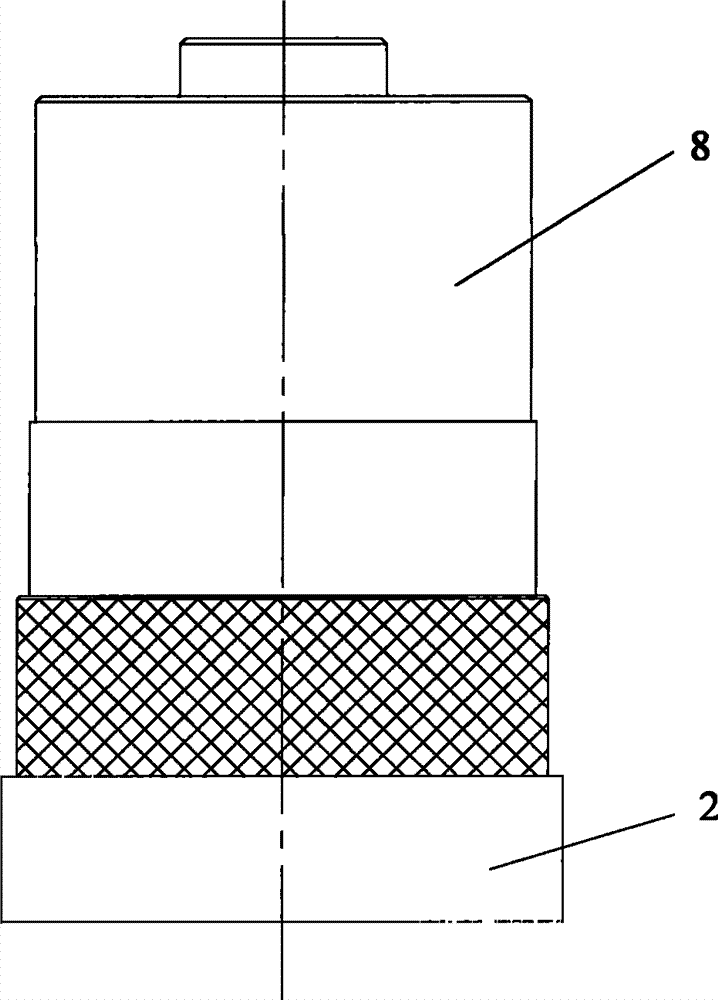

[0020] Such as figure 1 As shown, the oil filter for suppressing pressure pulsation is formed by fitting the filter cartridge 8 on the base 2 .

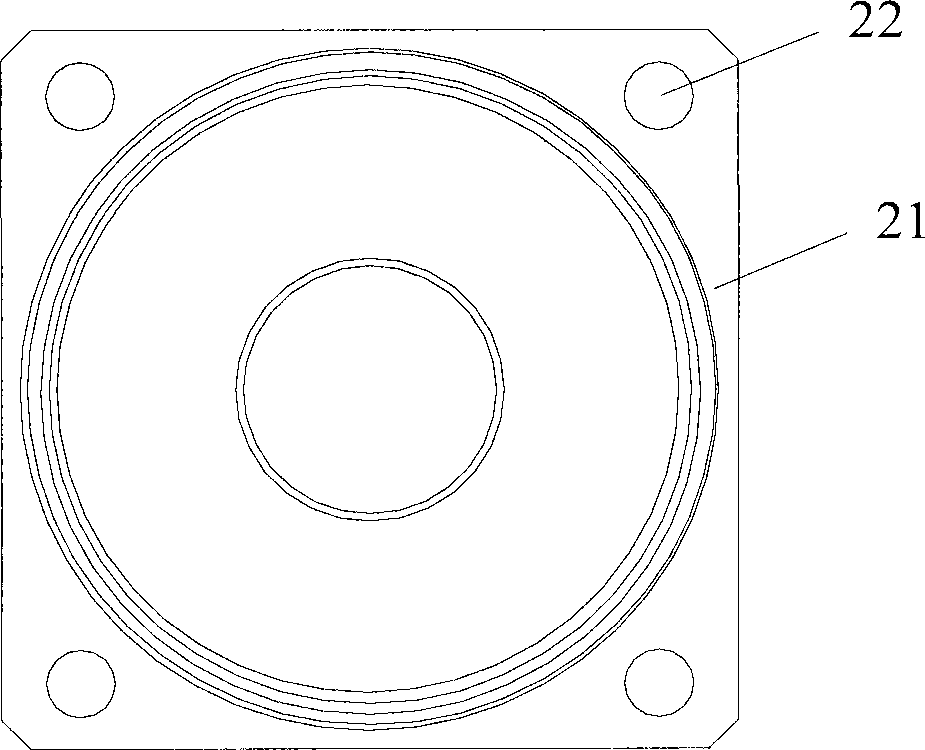

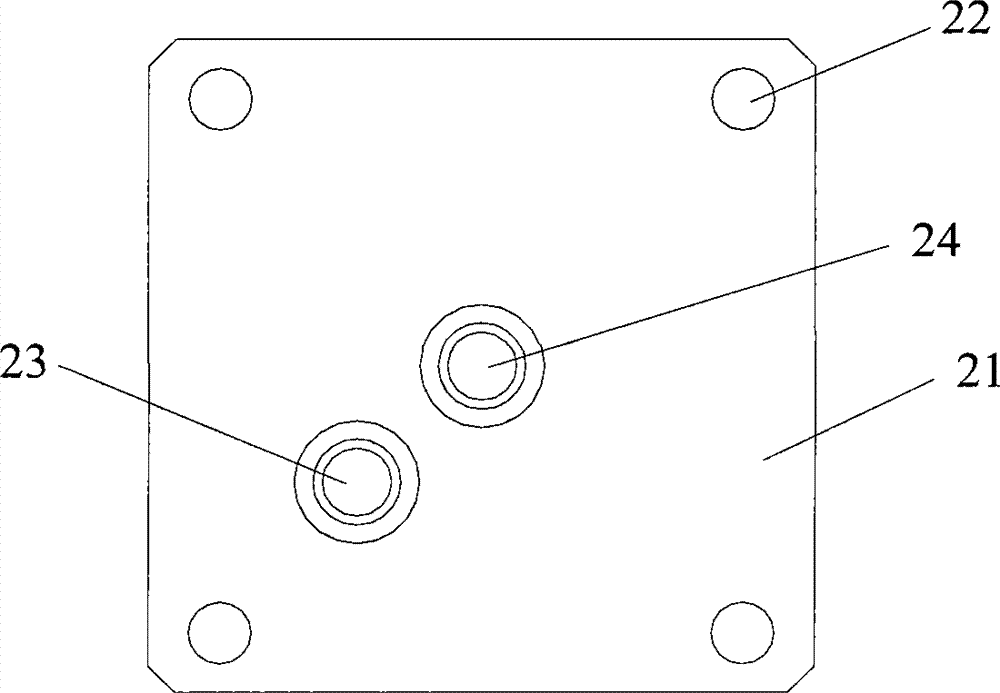

[0021] Such as Figure 2-4 As shown, the lower part of the base 2 is a square plate 21 with a ring-shaped boss and an internal thread on the upper side of the boss. Such as image 3 As shown, a through hole 22 is respectively opened at the four corners of the square support plate 21, and there are threads on the top of the through hole 22, so that the oil filter of the present invention can be installed on other components to facilitate the use of the oil filter of the present invention.

[0022] Such as image 3 As shown, an oil filter inlet 23 is opened outside the center gradient of the square support plate 21 , and an oil filter outlet 24 is opened at the center of the square support plate 21 . Such as Figure 4 As shown, a first sealing ring 3 is installed on the lower inner side of the outlet 24, and the upper side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com