Cylinder cooling structure for low-temperature start of engine

A cylinder cooling and engine technology, which is applied to engine cooling, engine starting, engine components, etc., can solve problems such as labor consumption and complexity, and achieve the effect of saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

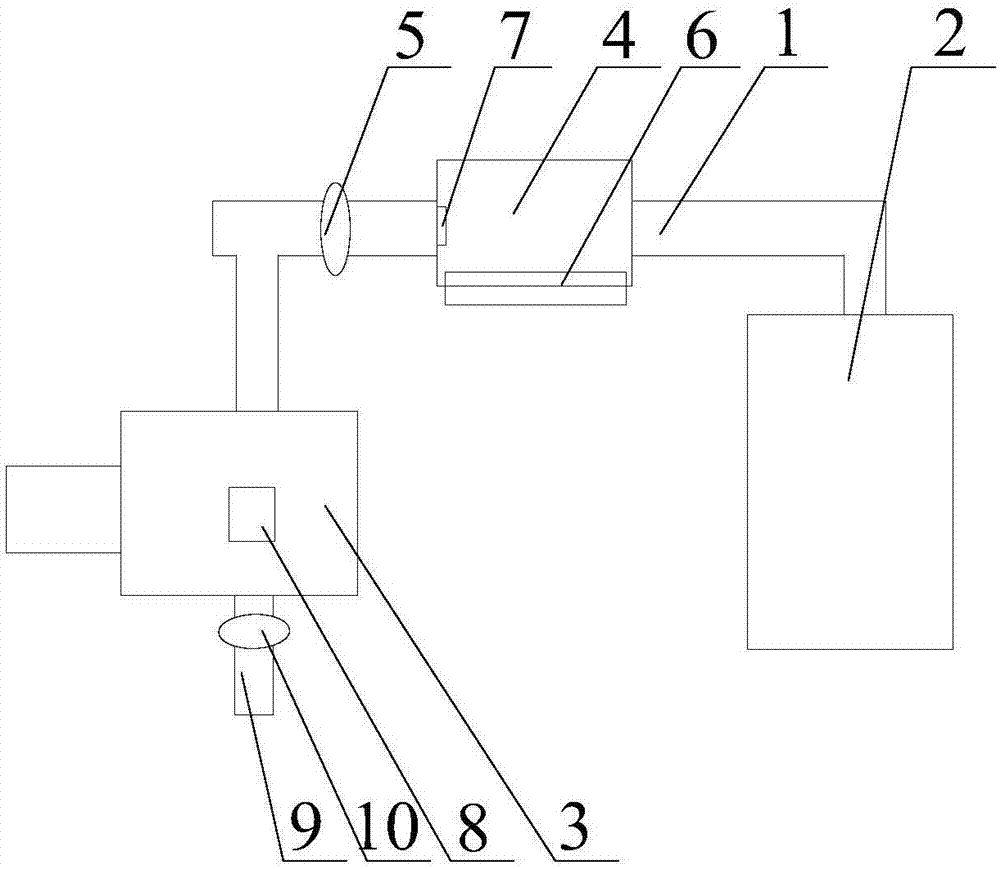

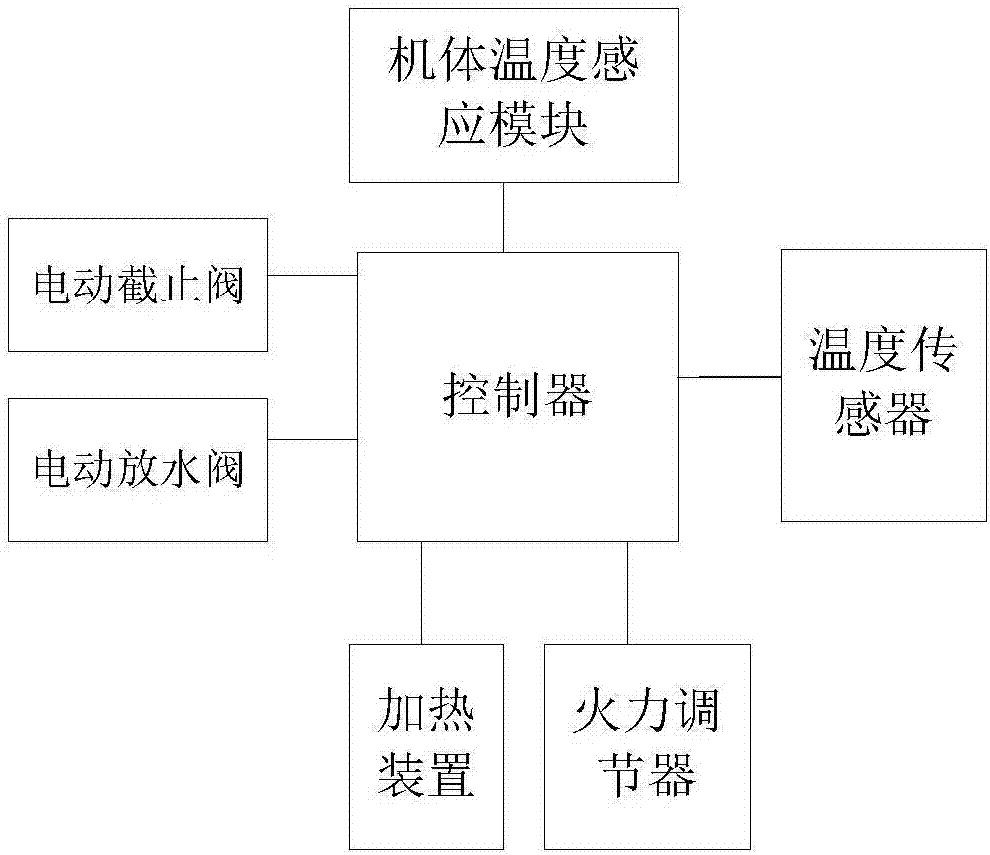

[0028] like Figure 1~2 As shown, the engine cylinder cooling structure for low-temperature starting of the present invention includes a water tank 2 and a cylinder head body 3 connected through a guide tube 1, and a heating cavity 4 and an electric shut-off valve 5 are arranged on the guide tube 1, and the electric shut-off valve The valve 5 is located between the heating cavity 4 and the cylinder head body 3, a heating device 6 and a temperature sensor 7 are also arranged in the heating cavity 4, an organic temperature sensing module 8 is arranged on the surface of the cylinder head body 3, and a controller is also included, The heating device 6, the electric stop valve 5, the temperature sensor 7, and the body temperature sensing module 8 are respectively connected to the controller, wherein:

[0029] Temperature sensor 7: collect the water temperature information in the heating cavity 4, and transmit the water temperature information to the controller;

[0030] Body tempe...

Embodiment 2

[0038] like Figure 1~2 As shown, the cylinder cooling structure of the engine at low temperature start of the present invention, on the basis of Embodiment 1, is also provided with a water discharge pipe 9 at the bottom of the cylinder head body 3, and the water discharge pipe 9 is connected with the internal cooling water cavity of the cylinder head body 3, An electric water discharge valve 10 is also arranged on the water discharge pipe 9, and the electric water discharge valve 10 is connected with the controller, wherein:

[0039] Controller: Receive the body temperature information transmitted by the body temperature sensing module 8, when the body temperature information is lower than 2 degrees Celsius, send the water discharge command to the electric water discharge valve 10;

[0040] Electric water discharge valve 10: receive the water discharge instruction transmitted by the controller, and open the valve. The electric drain valve 10 is the same valve as the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com