A test method for force-measuring bolt and axial force

A test method and technology of axial force, which is applied to measure torque/torsional force and other directions during tightening, can solve the problems that the strain temperature change cannot be compensated, the moisture-proof seal cannot be realized, and the wires are easy to be spliced, etc. It achieves convenient calibration and sensitive response , calculate the simple effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described,

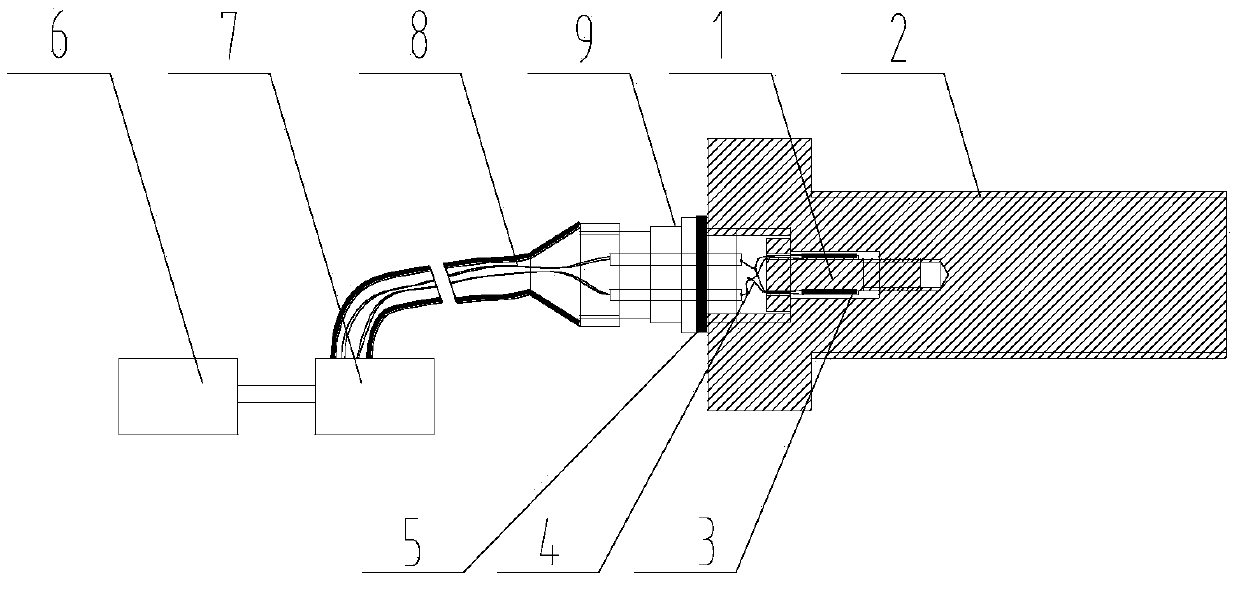

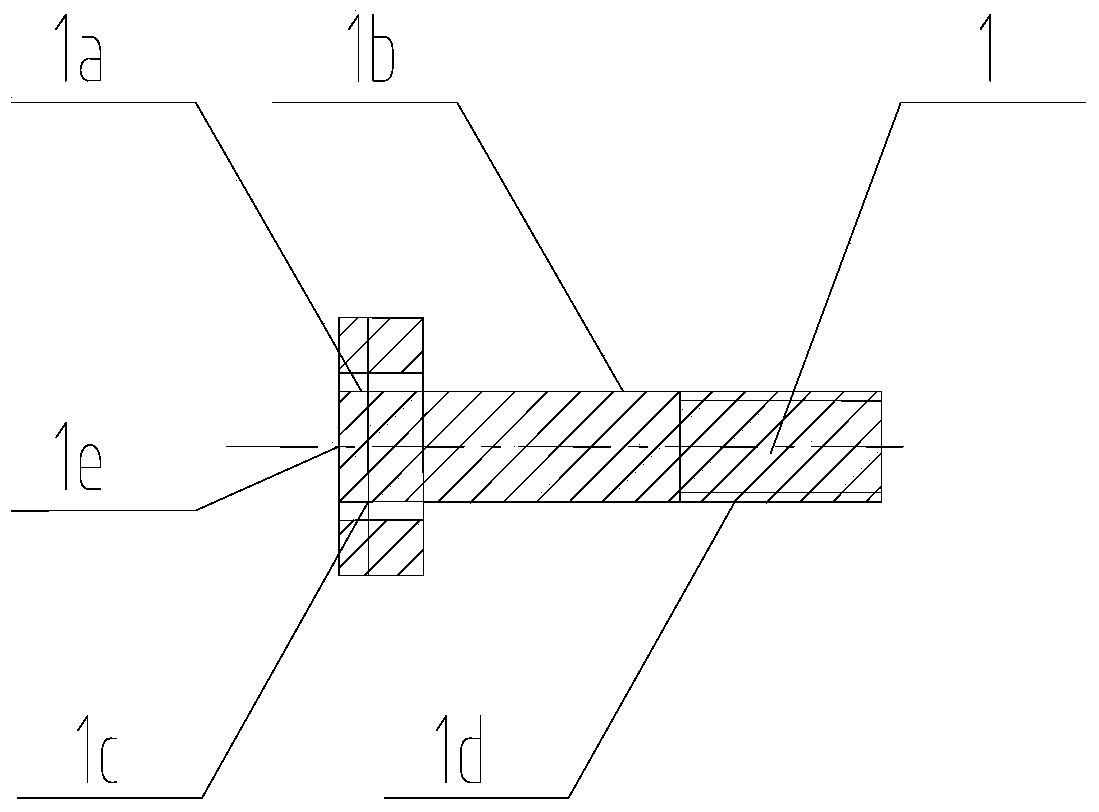

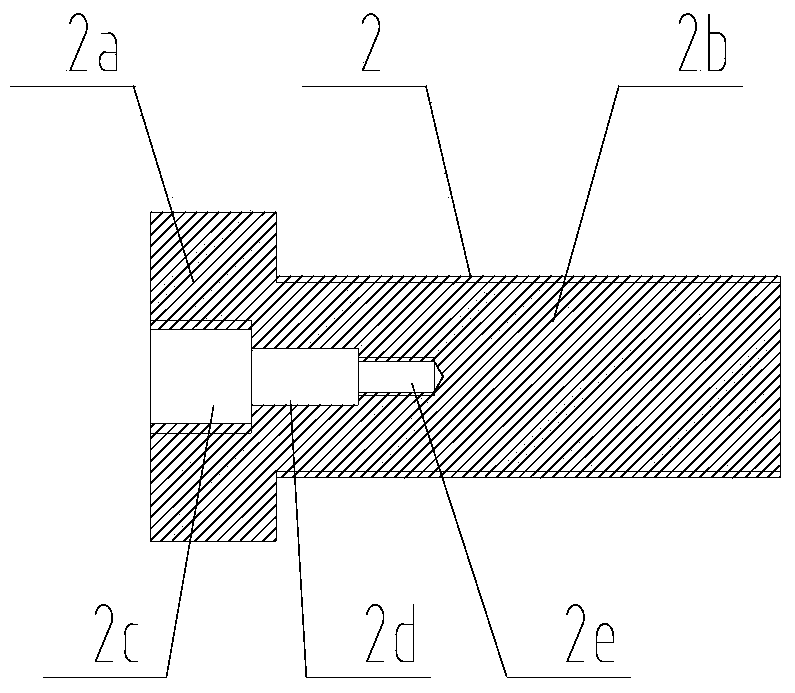

[0032] Such as Figure 1 to Figure 5 As shown, the present invention provides a force-measuring bolt. The bolt 2 includes a bolt head 2a and a screw rod 2b. An inner hole 2d is set on the bolt head 2a and extends toward the screw rod 2b. A core body 1 is fixed in the inner hole of the bolt. The core body 1 is pasted with a strain gauge 3 , one end of the core body 1 is fixed in the bolt rod 2 b , and the other end is fixed in the bolt head 2 a , and the strain gauge 3 is connected to the strain test unit 6 through the strain test line 4 .

[0033] One end of the core 1 is provided with a core thread 1d, and a corresponding bolt internal thread 2e is provided at an inner position of the screw 2b, and the core 1 and the screw 2b are screwed and fixed.

[0034] The other end of the core 1 is provided with a core installation surface 1e, and a core inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com