Test piece gripper and spin multiphase flow erosive wear test machine

A wear test and specimen clamping technology, applied in the direction of testing wear resistance, instruments, scientific instruments, etc., can solve the problems of complex, difficult to predict, and troubled the safe operation of fluid pipelines, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

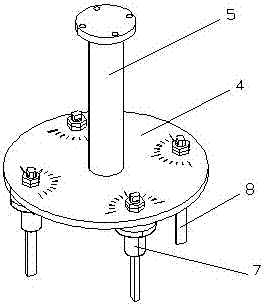

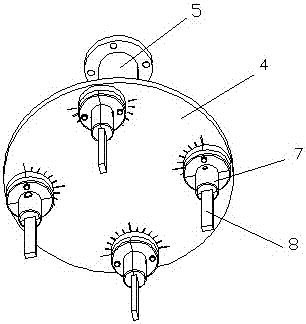

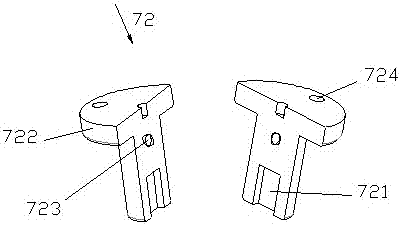

[0030] Please refer to Figure 1 to Figure 4 , figure 1 It is a structural schematic diagram of a specific embodiment of the specimen holder provided by the present invention, figure 2 for figure 1 bottom view of image 3 for figure 1 An exploded view of the clamp block of the specimen holder shown, Figure 4 for figure 1 Schematic diagram of the structure of the base of the specimen holder shown.

[0031] In a specific embodiment, the present invention provides a specimen holder for an erosion and wear testing machine, comprising a base 71 and two clamping blocks 72; the clamping blocks 72 are semi-cylindrical, with a clamp at one end mouth 721, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com