Diffusion sheet and preparation method thereof

A diffusion sheet and diffusion layer technology, applied in optics, instruments, nonlinear optics, etc., can solve the problem of damage to sensitive components of liquid crystal displays, and achieve the effect of reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

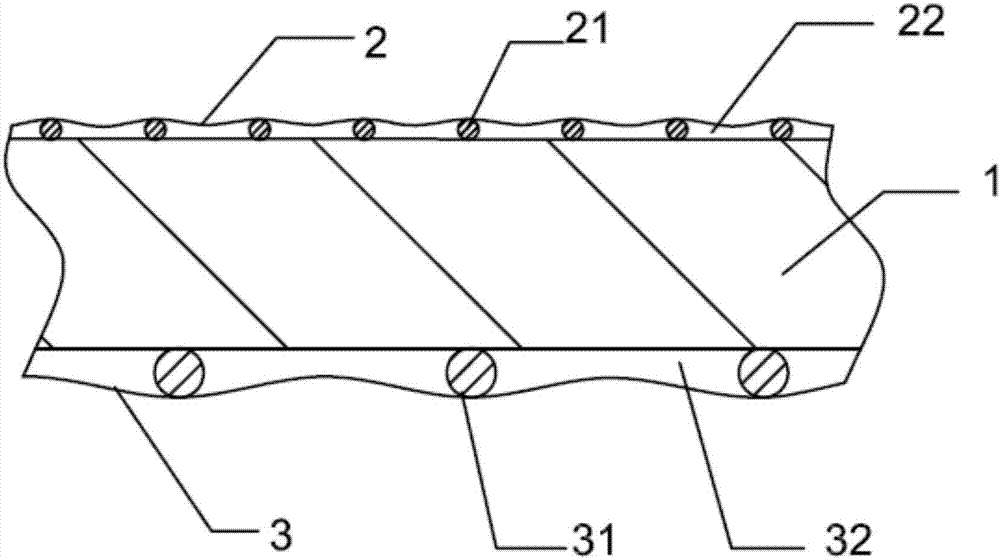

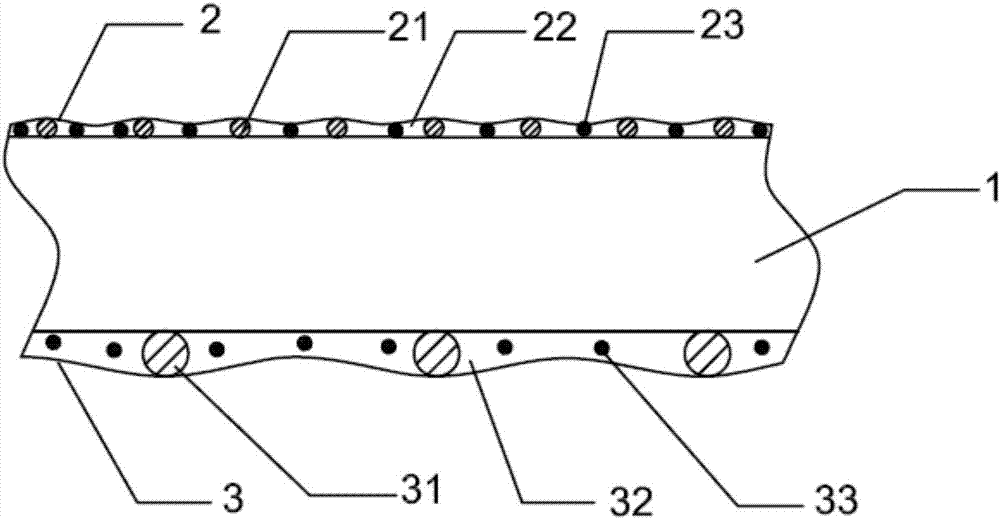

[0028] Such as figure 2 As shown, a diffusion sheet includes a diffusion layer 2, a transparent substrate layer 1 and a protective layer 3 arranged in sequence (that is, the diffusion layer 2 and the protective layer 3 are respectively located on both sides of the transparent substrate layer 1), and the transparent substrate The material layer 1 is provided with a first surface and a second surface opposite to each other;

[0029] The diffusion layer 2 includes a first adhesive 22, a plurality of diffusion particles 21 and a plurality of first conductive particles 23, and the diffusion particles 21 and the first conductive particles 23 are bonded on the first adhesive 22. On the first surface of the transparent substrate layer 1 , at least one first conductive particle 23 is arranged between two adjacent diffusion particles 21 , and the diameter of the diffusion particle 21 is larger than the diameter of the first conductive particle 23 . In this embodiment, a plurality of f...

Embodiment 2

[0037] A method for preparing a diffusion sheet, comprising:

[0038] Step 1. Prepare the diffusion layer coating solution: add the first adhesive 22, the diffusion particles 21, and the first conductive particles 23 in sequence, stir evenly, and adjust to the set viscosity;

[0039] Step 2. Prepare the diffusion layer 2: apply the diffusion layer coating solution prepared in step 1 on the first surface of the transparent substrate layer 1, and put it into an oven at 50°C-200°C for aging for 1-10 hours. The first surface of the substrate layer 1 forms a diffusion layer 2;

[0040] Step 3, preparing the protective layer coating solution: adding the second adhesive 32, the protective particles 31, and the second conductive particles 33 in sequence, stirring evenly, and adjusting to a set viscosity;

[0041] Step 4, prepare the protective layer 3, apply the protective layer coating solution prepared in step 3 on the second surface of the transparent substrate layer 1, and add it...

Embodiment 3

[0044] A backlight module, the backlight module includes a diffusion sheet, and the diffusion sheet is the diffusion sheet described in Embodiment 1 or the diffusion sheet prepared according to the preparation method of the diffusion sheet described in Embodiment 2 .

[0045] In summary:

[0046] The present invention increases the conductive particles in the diffusion layer and the protective layer, so that the surface of the diffusion sheet forms a conductive layer, thereby reducing the resistivity of the surface of the diffusion sheet. Since the speed of charge leakage is inversely proportional to the resistance value of the surface of the diffusion sheet, it can The static charge generated on the surface due to friction and other reasons can be quickly leaked, effectively preventing the static charge from being accumulated and quickly released to damage the sensitive components in the liquid crystal display module to which the diffusion sheet of the present invention is ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com