Sunlight tracking and reflecting device

A reflective device and solar light technology, applied in the field of solar power generation, can solve the problems of reduced tracking accuracy, damage to the heat collector, unfavorable driving angle for snow removal and heliostat rotation protection, etc., and achieve the effect of improving control accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

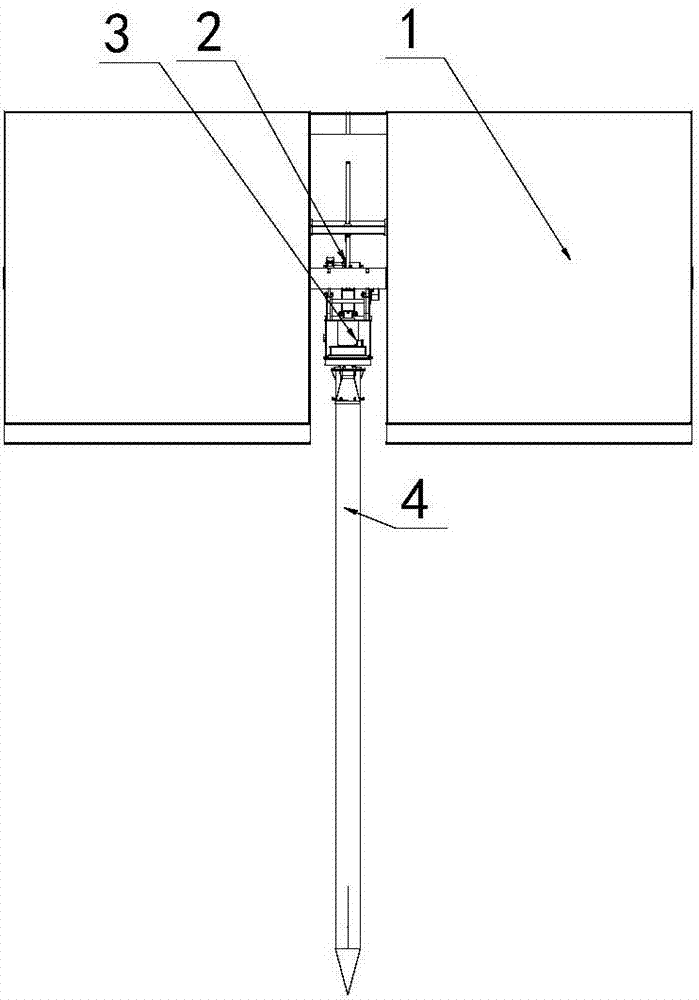

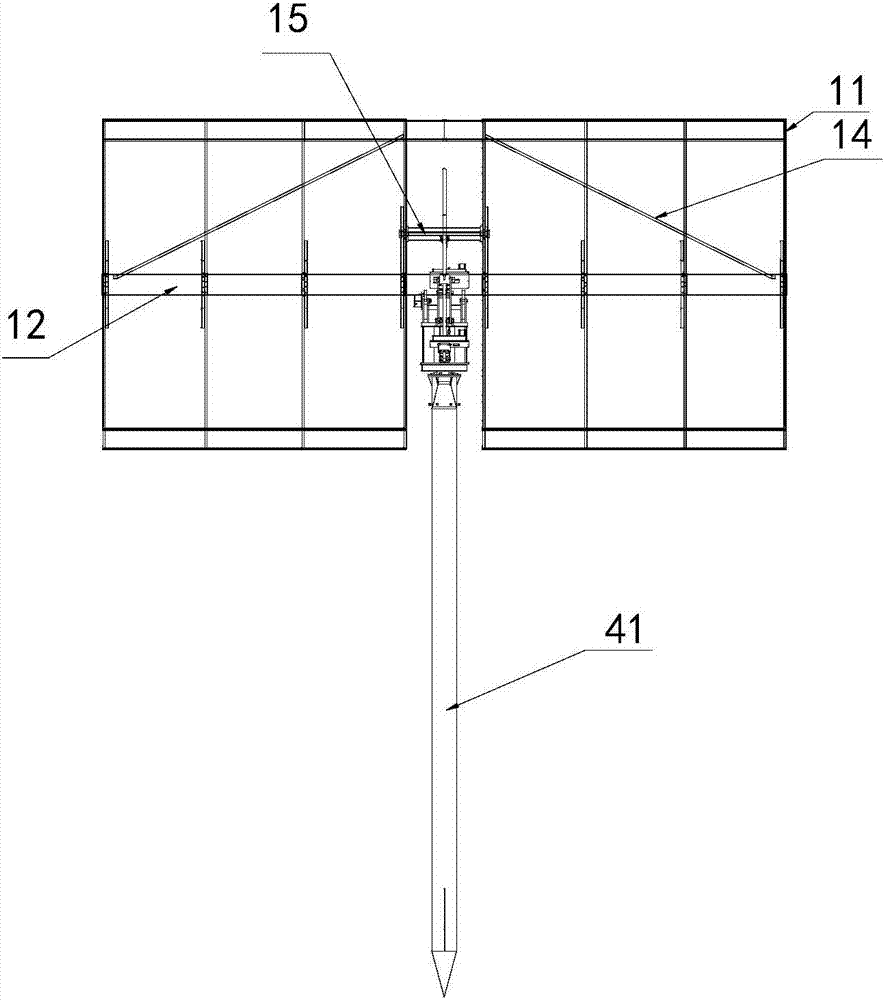

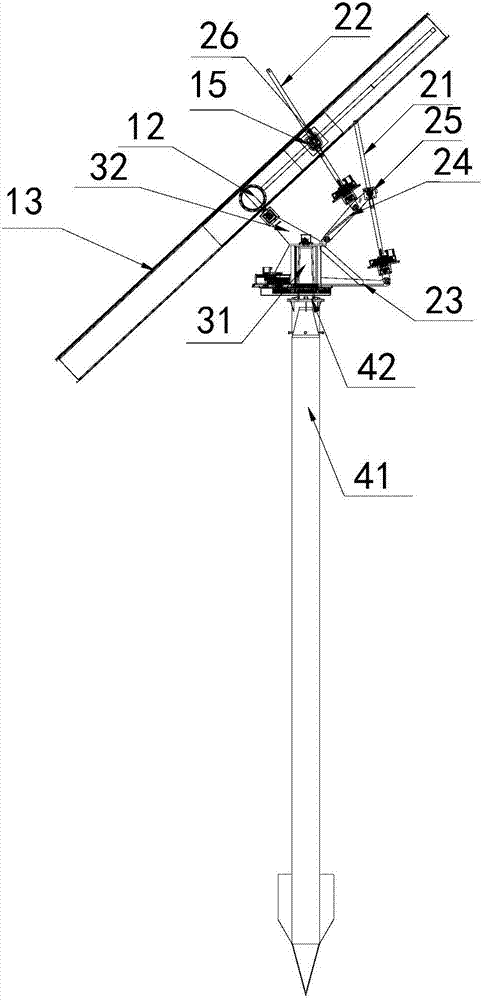

[0028] The invention provides a solar ray tracing reflection device, such as Figure 1-5 As shown, it includes: a mirror assembly 1, a pitch drive assembly 2, an azimuth drive assembly 3 and a column assembly 4, the pitch drive assembly 2 is respectively connected to the mirror assembly 1 and the azimuth drive assembly 3, and the column assembly 4 passes through the flange Rotatably connected below the azimuth drive assembly 3, the mirror assembly 1 rotates in a vertical plane driven by the pitch drive assembly 2, and the mirror assembly 1 rotates in the azimuth drive assembly 3 Under the action of rotating in the horizontal plane, the pitch drive assembly 2 pushes the mirror assembly 1 to rotate within a vertical range of 180° through a double push rod structure, which is convenient for mirror control and snow cleaning.

[0029] The reflector assembly 1 includes a reflector frame 11 and at least one reflector 13 installed in the reflector frame 11, the reflector frame 11 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com