Epitaxial wafer for gallium-nitride-based light emitting diode, and preparation method for epitaxial wafer

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the luminous efficiency of light-emitting diodes, and achieve the effect of improving the ability of compound light emission, shortening the transmission distance, and improving the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

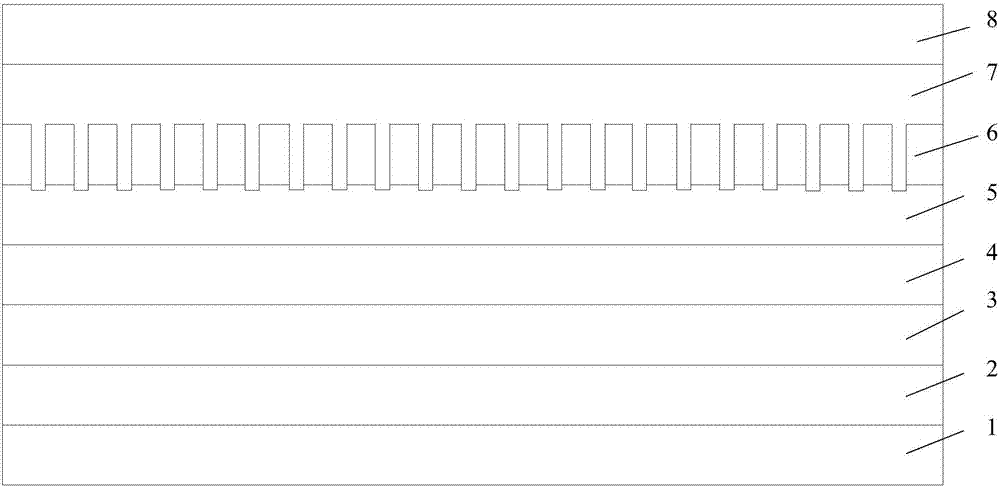

[0035] An embodiment of the present invention provides an epitaxial wafer of a gallium nitride-based light-emitting diode, see figure 1 , the epitaxial wafer includes a sapphire substrate 1, and a GaN buffer layer 2, an undoped GaN layer 3, an N-type GaN layer 4, a multi-quantum well layer 5, a P-type AlGaN layer 6, P-type GaN layer 7 .

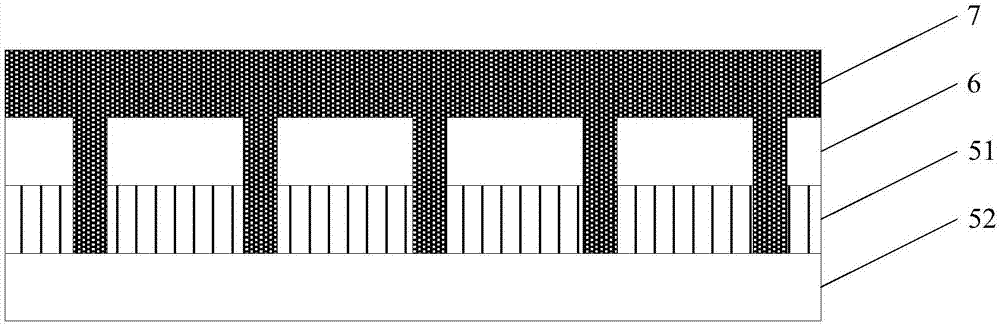

[0036] In this embodiment, the multi-quantum well layer is formed by sequentially stacking a plurality of sub-layers, and each sub-layer includes a quantum well layer and a quantum barrier layer stacked on the quantum well layer. like figure 2 As shown, there are several through holes in the P-type AlGaN layer 6 and the quantum barrier layer 51 closest to the P-type AlGaN layer. The quantum well layer 52 of the AlGaN layer, and the P-type GaN layer 7 are filled in the through hole.

[0037] Optionally, the cross-section of the through hole perpendicular to the stacking direction of the epitaxial wafers may be square, circular, star-shaped...

Embodiment 2

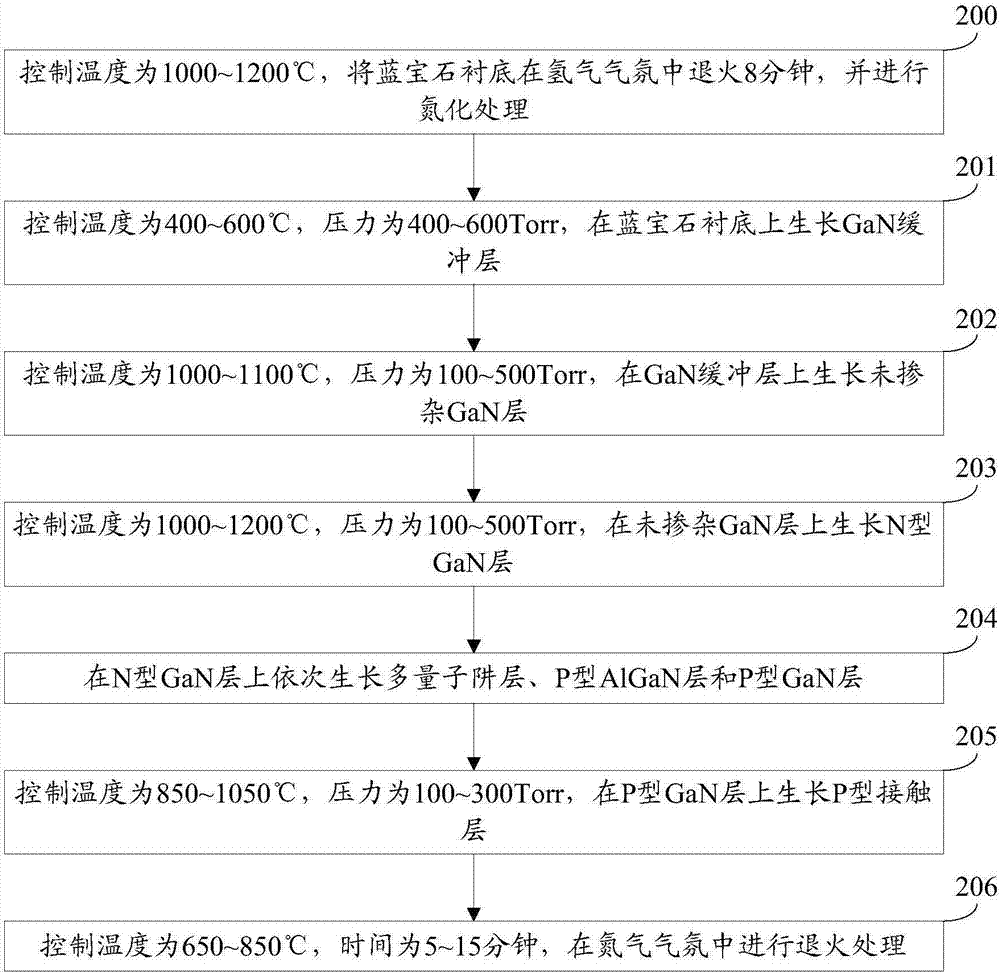

[0053] An embodiment of the present invention provides a method for preparing an epitaxial wafer of a gallium nitride-based light-emitting diode, which is suitable for preparing the epitaxial wafer provided in Embodiment 1. See image 3 , the preparation method comprises:

[0054] Step 200: Control the temperature to 1000-1200° C., anneal the sapphire substrate in a hydrogen atmosphere for 8 minutes, and perform nitriding treatment.

[0055] Understandably, step 200 can clean the surface of the sapphire substrate.

[0056] In this embodiment, the sapphire substrate 1 adopts (0001) crystal orientation sapphire.

[0057] Step 201: Control the temperature to 400-600° C. and the pressure to 400-600 Torr to grow a GaN buffer layer on the sapphire substrate.

[0058] Optionally, the thickness of the GaN buffer layer may be 15-35 nm.

[0059] Optionally, after step 201, the preparation method may further include:

[0060] The control temperature is 1000-1200° C., the pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com