Graphene battery material mixing compaction device

A technology of battery materials and compacting devices, which is applied in the direction of mixers, battery electrodes, circuits, etc., to achieve the effect of avoiding waste of resources and facilitating mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

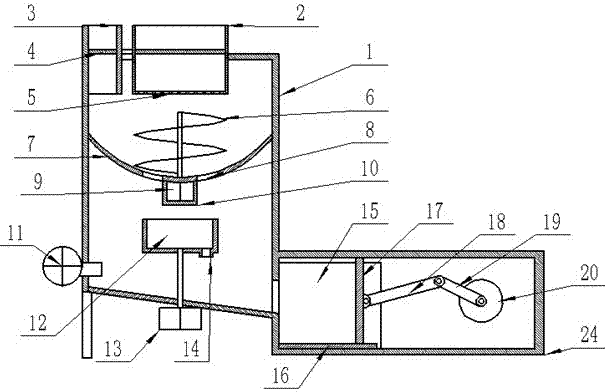

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

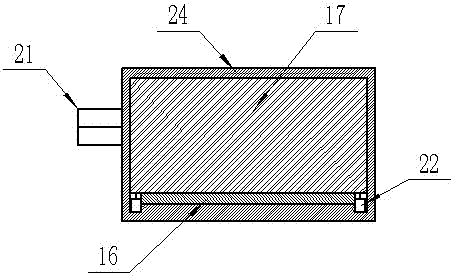

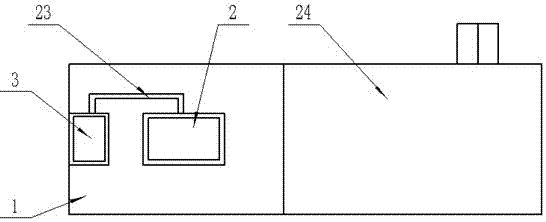

[0017] see Figure 1-3 , a graphene battery material mixing and compacting device, comprising a main box 1 and an auxiliary box 24; Material curved panel 7, through hole 5, spiral stirring plate 6, first motor 9, motor cover 10, ring mouth 8, rotating drum 12, second motor 13, discharge port 14 and blower 11; The feed pipe 3 It is arranged on the left side of the upper end surface of the main box body 1, and the feed pipe 3 is convenient for workers to put in battery materials; the bulk material pipe 2 is arranged in the middle of the upper end surface of the main box body 1, and the bulk material pipe 2 is convenient for workers to put in graphene materials ; The partition 4 has two pieces, which are horizontally inserted from the rear side of the feed pipe 3 and the bulk material pipe 2 respectively. The partition 4 is used to keep the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com