Spiral welded pipes for gas insulated transmission lines

A transmission line, gas insulation technology, applied in the direction of circuits, insulators, insulators, etc., can solve the problems of difficult to correct roundness, limited application scope of gas-insulated metal-enclosed transmission technology, and more gas leakage points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

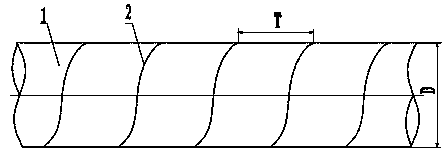

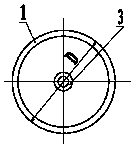

[0020] Such as figure 1 , figure 2 As shown, the aluminum alloy steel strip coil is used as the raw material, and the aluminum alloy strip with a width of 1.75 m is rolled in a spiral shape and welded into a cylindrical welded pipe body 1. The length of the welded pipe body 1 is any length, and the welded pipe body 1 The pitch T=2.30m of the spiral weld 2 on the top, the outer diameter D=φ900m. The thickness of the pipe wall is 10mm, and the design rated voltage of the welded pipe body 1 is 1100KV, so the ratio of the rated voltage V to the outer diameter D of the welded pipe body V / D=1.22KV / mm, and the ratio of the roundness t of the welded pipe body 1 to the outer diameter t / D is less than 1 / 1000, and the straightness of the welded pipe body is 1mm / m.

Embodiment 2

[0022] Such as figure 1 , figure 2As shown, the aluminum alloy steel strip coil is used as the raw material, and the aluminum alloy strip with a width of 1.60 m is rolled in a spiral shape and welded into a cylindrical welded pipe body 1. The length of the welded pipe body 1 is any length, and the welded pipe body 1 The pitch T=2.0m of the spiral weld 2 on the top, the outer diameter D=φ810m. The thickness of the pipe wall is 8mm, and the design rated voltage of the welded pipe body 1 is 750KV, so the ratio of the rated voltage V to the outer diameter D of the welded pipe body V / D=0.926KV / mm, and the ratio of the roundness t of the welded pipe body 1 to the outer diameter D t / D=0.8 / 1000, the straightness of the welded pipe body is 0.8mm / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com