Method for making cathode structure of field emitting display

A technology of cathode structure and manufacturing method, which is applied in the direction of electroluminescence light source, lighting device, light source, etc., can solve the problems of uneven electric field effect, uneven current density of electron beam, difficult to compact structure, etc., and achieve uniformity of brightness , Improve the uniformity of the electric field and reduce the production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Relevant technical content and detailed description of the present invention, now cooperate accompanying drawing to explain as follows:

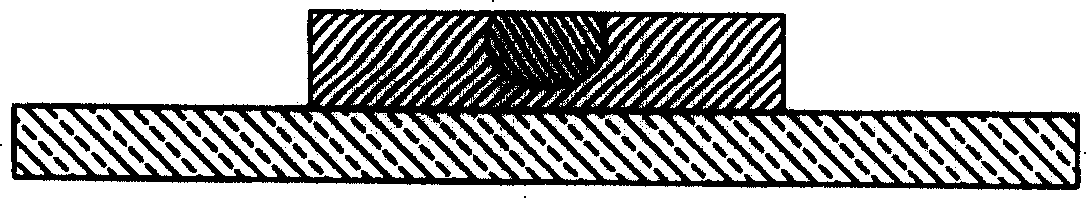

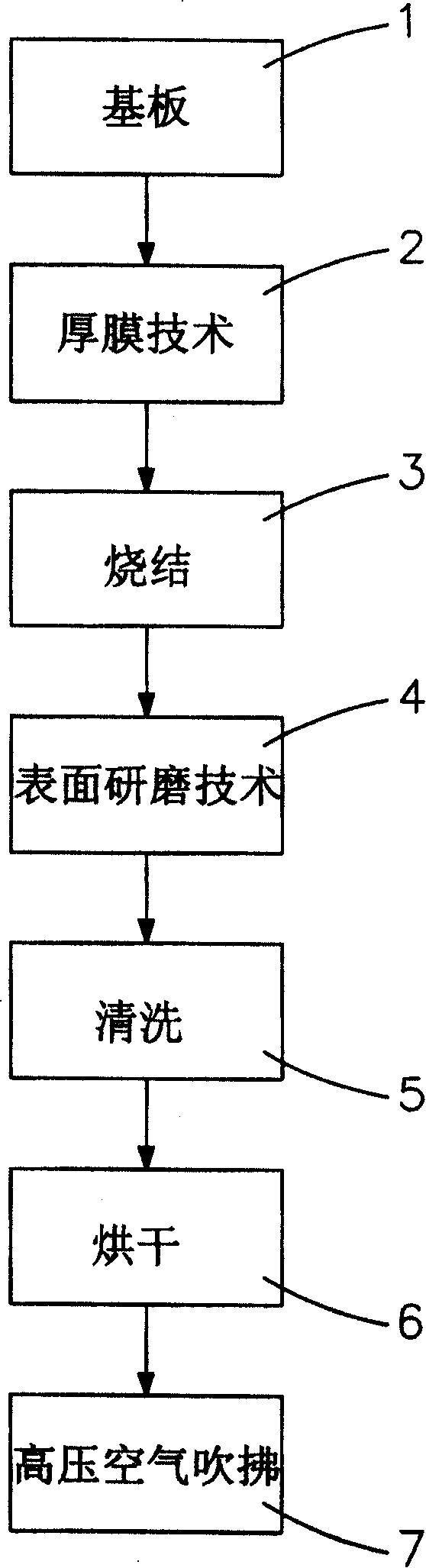

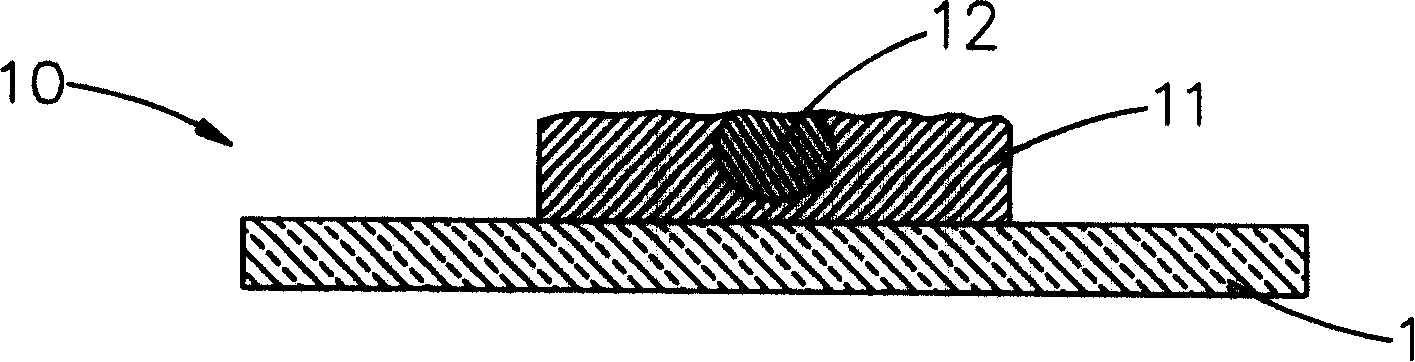

[0027] figure 2 , image 3 It is a schematic diagram of the fabrication process and a schematic diagram of the cathode structure of the cathode structure of the field emission display of the present invention. Such as figure 2 , image 3 As shown, the method for manufacturing the cathode structure of the field emission display of the present invention is mainly to use grinding technology to level the surface of the electrode layer of the cathode structure after the cathode structure of the field emission display is manufactured, so that the surface flatness of the electrode layer is improved, and It is easier to make and can reduce the production cost.

[0028] When making the cathode structure, take a substrate 1 first, and the substrate 1 is made of glass material;

[0029] The first electrode layer 11 and the second electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com