Method for processing steel member bush step holes with guaranteed coaxiality

A processing method and step hole technology, which is applied in the field of high-precision parts processing, can solve the problems of low qualification rate of key parts and inability to guarantee task delivery, and achieve the effect of saving processing costs and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

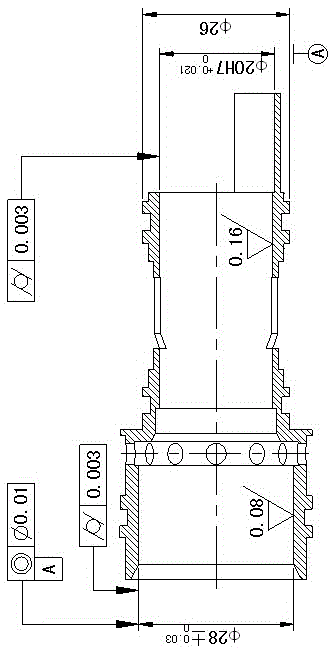

[0066] Quenching parts such as figure 1 As shown, the material is 9Cr18. Heat treatment requirements: hardness ≥ 56HRC. The part is a thin-walled part, which is easily deformed during processing. The qualified rate of parts adopting the processing method of the present invention is above 98%.

Embodiment 2

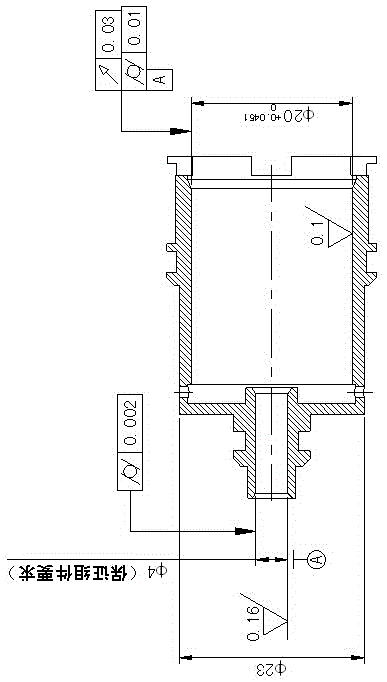

[0068] Carburized parts such as figure 2 As shown, material: 12CrNi3A, heat treatment requirements: carburizing depth 0.6 ~ 0.8mm (design drawing requirements 0.4 ~ 0.7mm), hardness ≥ 56HRC. The difficulty in processing this part is that the φ4 hole is very small, and the coaxiality is difficult to process and difficult to guarantee. By adopting the processing method of the invention, the cylindricity of the large hole of the part and the run-out value of the large hole to the small hole can meet the technical requirements, and the processing quality is stable. Since the position of the φ4 small hole is relatively deep, the length of the grinding wheel rod is relatively large. Therefore, the toughness of the grinding wheel rod is poor, resulting in poor cylindricity and surface roughness of the φ4 hole, and a certain machining allowance is required (usually 0.02~ 0.03mm) Grinding hole correction in 100 processes. The passing rate is 96%.

Embodiment 3

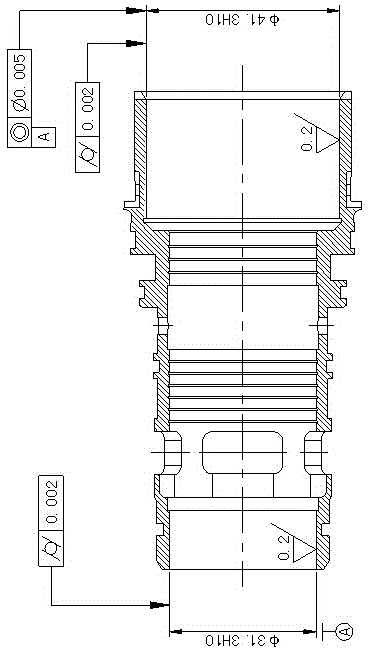

[0070] Nitriding parts such as image 3 As shown, material: 4Cr14Ni14W2Mo, heat treatment requirements: nitriding depth ≥ 0.1mm (the design requires nitriding depth not less than 0.07mm), hardness ≥ 700HV. The difficulty in processing this type of parts is that the margin of the inner hole of the part after nitriding is very small (the margin on one side is 0.03-0.05mm). scrapped. Therefore, it is critical to control the nitriding deformation of parts. After the hot and cold coordination with the heat meter branch factory, the machining branch factory guarantees the coaxiality φ0.01 before heat treatment, and the heat meter branch factory guarantees the coaxiality φ0.03 after heat treatment. After heat treatment, the coaxiality of the parts is corrected to φ0.005max by CNC internal grinding. The coaxiality of the two holes after grinding can meet the requirements of the design drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com