Wire feeder

A pre-feeding and wire-feeding wheel technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problem of restricting the overall performance of wire harness processing automation equipment, unable to quickly and automatically handle abnormalities, and effectively compatible with wire materials, etc. Problems, achieve sensitivity and durable, fast response handling, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

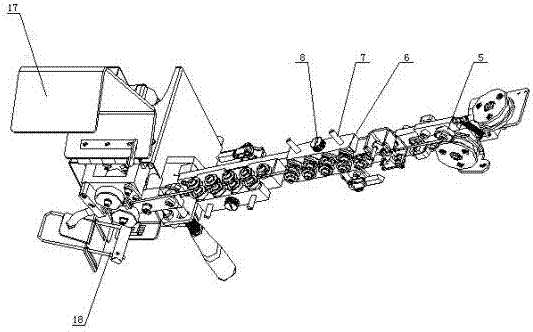

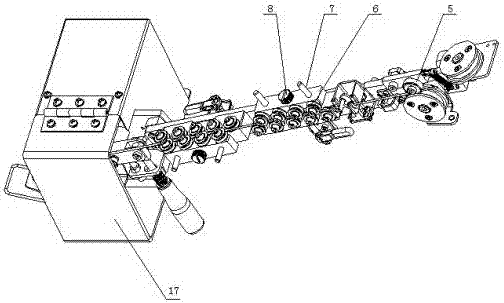

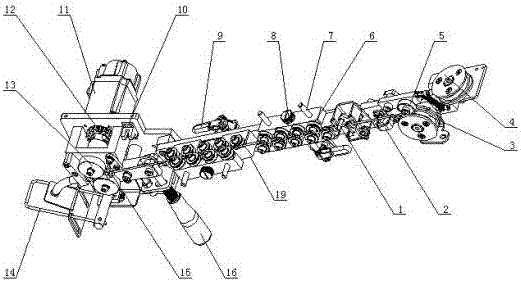

[0017] Such as Figure 1-3 As shown, a pre-feeding device includes a pre-feeding device body 18, and the pre-feeding device body 18 includes a flip cover 17, a thread missing detection shaft 1, a thread jam detection piece 2, a vertical guide wheel 3, and a horizontal guide wheel 4. Crimping bearing 5, wire pulley 6, guide rod 7, wire adjustment knob 8, elastic clamp 9, cover sensor 10, motor 11, gear 12, wire feeding wheel 13, wire feeding induction frame 14, wire magnet Eye 15, wire feeding wheel control lever 16 and cross bar 19, described flip 17 inside is provided with flip sensor 10, motor 11, gear 12, wire feeding wheel 13 and wire feeding induction frame 14, and described gear 12 one end is provided with Motor 11, the other end of the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com