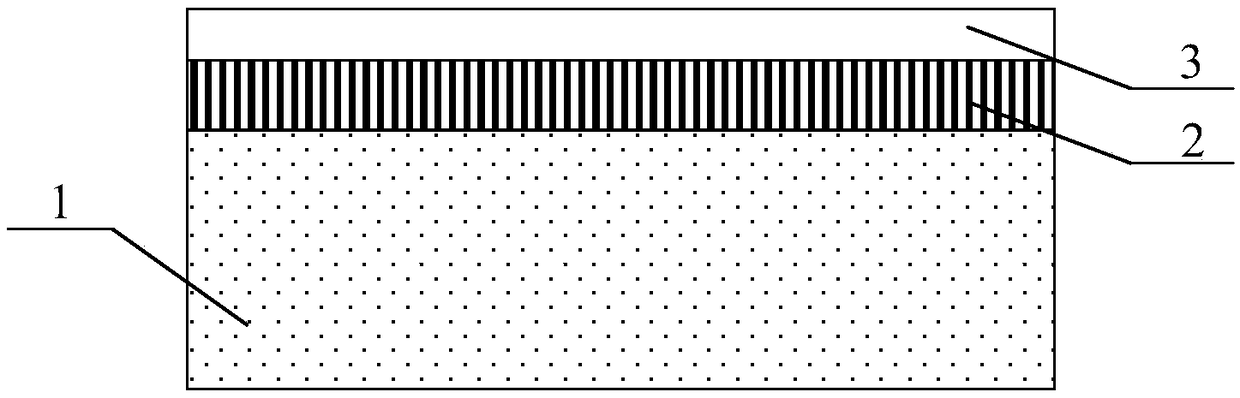

A graphene-porous silicon material with high photoluminescence performance and preparation method thereof

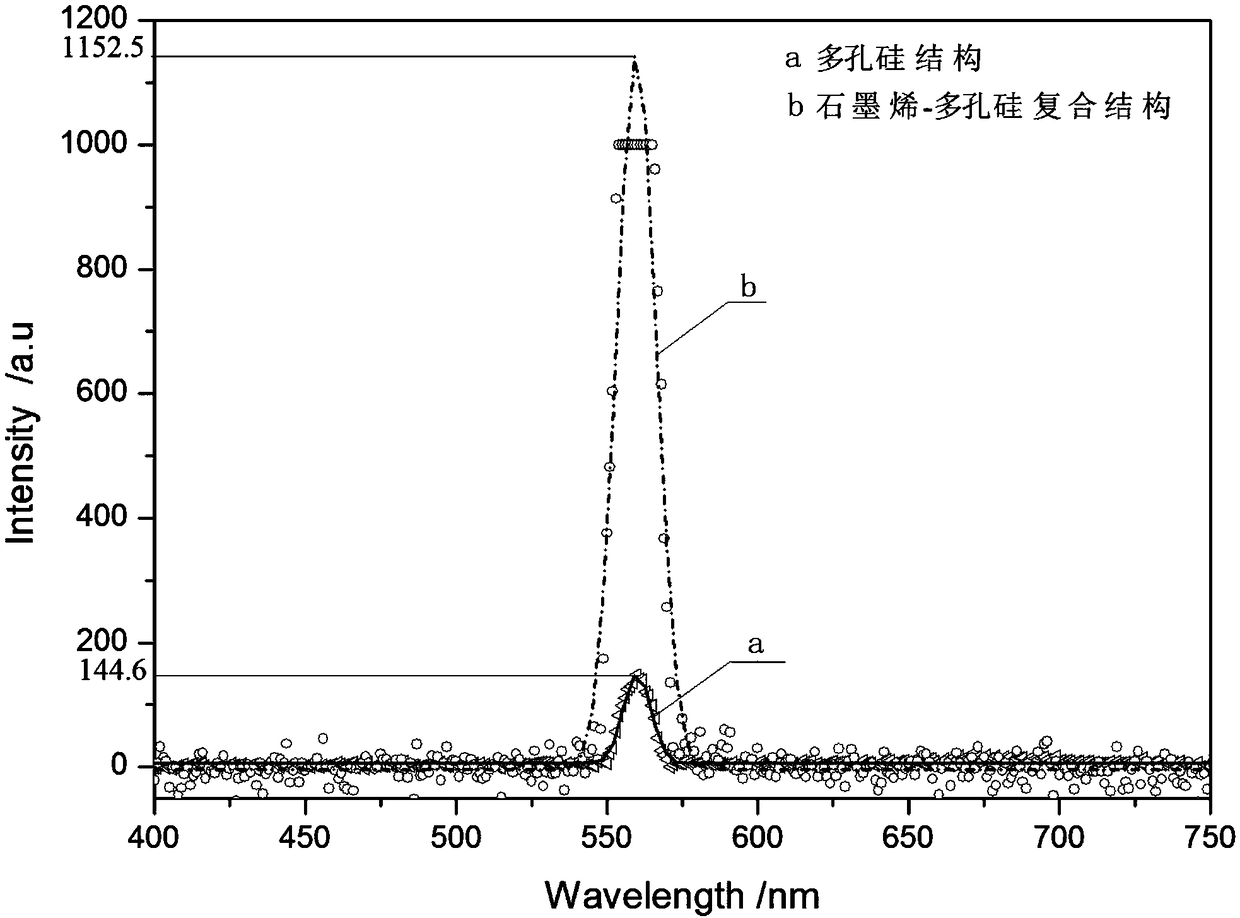

A technology of porous silicon and graphene, applied in related application fields, can solve the problem of low photoluminescence performance of porous silicon, and achieve the effect of broadening optical application prospects, short time, and simple and easy steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Select material: select the resistance of 3 ~ 8Ω.cm 2 1. An n-type monocrystalline silicon wafer (both sides polished) with a thickness of 450 μm and a crystal orientation of [100], with a size of 1.6 cm×1.6 cm.

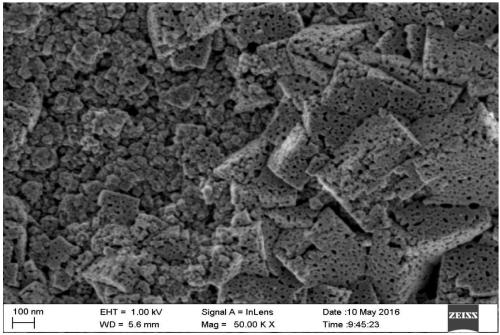

[0033] 2. Preparation of porous silicon: The above-mentioned selected samples were ultrasonically cleaned in absolute ethanol and deionized water for 20 minutes in sequence. Then remove it with tweezers and dry it with a nitrogen gun for later use. The prepared silicon wafer was electrochemically etched in a mixed solution of hydrofluoric acid / absolute ethanol with a volume ratio of 1:1, the current was set to 10mA, and the etching time was 10 minutes. After the etching was completed, it was cleaned with deionized water and washed with Blow dry with a nitrogen gun, such as figure 2 shown.

[0034] 3. Transfer of graphene: Cut the copper foil covered with graphene so that its size is equivalent to the size of the porous silicon. After the cutting is comp...

Embodiment 2

[0037] 1. Select material: select the resistance of 3 ~ 8Ω.cm 2 1. An n-type monocrystalline silicon wafer (both sides polished) with a thickness of 450 μm and a crystal orientation of [100], with a size of 1.6 cm×1.6 cm.

[0038] 2. Preparation of porous silicon: The above-mentioned selected samples were ultrasonically cleaned in absolute ethanol and deionized water for 20 minutes in sequence. Then remove it with tweezers and dry it with a nitrogen gun for later use. The prepared silicon wafer was electrochemically etched in a mixed solution of hydrofluoric acid / absolute ethanol with a volume ratio of 1:1, the current was set to 30mA, and the etching time was 10 minutes. After the etching was completed, it was cleaned with deionized water and washed with Blow dry with a nitrogen gun.

[0039] 3. Transfer of graphene: Cut the copper foil covered with graphene so that its size is equivalent to the size of the porous silicon. After the cutting is completed, place the copper fo...

Embodiment 3

[0041] 1. Select material: select the resistance of 3 ~ 8Ω.cm 2 1. An n-type monocrystalline silicon wafer (both sides polished) with a thickness of 450 μm and a crystal orientation of [100], with a size of 1.6 cm×1.6 cm.

[0042]2. Preparation of porous silicon: The above-mentioned selected samples were ultrasonically cleaned in absolute ethanol and deionized water for 20 minutes in sequence. Then remove it with tweezers and dry it with a nitrogen gun for later use. The prepared silicon wafers were electrochemically etched in a mixed solution of hydrofluoric acid / absolute ethanol with a volume ratio of 1:1, the current was set to 30mA, and the time was 10 minutes. After the etching was completed, it was cleaned with deionized water and nitrogen gas Gun blow dry.

[0043] 3. Transfer of graphene: Cut the copper foil covered with graphene so that its size is equivalent to the size of the porous silicon. After the cutting is completed, place the copper foil on the glass sheet,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com