Method for preparing sulfur-doped molybdenum dioxide nanosheets with adjustable shapes and band gaps

A molybdenum dioxide and nanosheet technology, applied in chemical instruments and methods, molybdenum oxide/molybdenum hydroxide, inorganic chemistry, etc., can solve the problems of cumbersome process, unadjustable band gap, low yield, etc., and achieve photoluminescence. Good, cheap and non-toxic materials, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare molybdenum dioxide nanosheets according to the method provided by the present invention: molybdenum trioxide powder 5mg, sulfur powder 100mg, high temperature zone growth temperature (700°C, 750°C and 800°C), heating rate 50°C / min; low temperature zone growth temperature 150°C ℃, heating rate 10℃ / min; argon 100sccm, holding time 10min, cooling down to room temperature and taking out the sample. Get product MoO 2 -1, MoO 2 -2 and MoO 2 -3 for subsequent analysis and characterization.

[0030] Concrete preparation steps are as follows:

[0031] (1) substrate treatment, the SiO 2 / Si substrate substrates were ultrasonicated for 10 min under deionized water, acetone and isopropanol to remove impurities and organic matter on the surface; 2 SO 4 :H 2 o 2 = Soak in 3:1 piranha lotion for 90 minutes; then use deionized water to sonicate for 15 minutes, and finally blow dry with an argon gun;

[0032] (2) Drug weighing and equipment debugging, weigh 5 mg of moly...

Embodiment 2

[0035] Molybdenum dioxide nanosheets are prepared according to the method provided by the invention: the growth temperature in the high temperature zone is 700°C, and the heating rate is 50°C / min; the growth temperature in the low temperature zone is 150°C, and the heating rate is 10°C / min; molybdenum trioxide powder (5mg, 10mg, 15mg),; sulfur powder 100mg, argon 100sccm, holding time 10min; after holding time 10min, cool down to room temperature and take out the sample. Get product MoO 2 -4, MoO 2 -5 and MoO 2 -6 for subsequent analysis and characterization.

[0036] (1) substrate treatment, the SiO 2 / Si substrate substrates were ultrasonicated for 10 min under deionized water, acetone and isopropanol to remove impurities and organic matter on the surface; 2 SO 4 :H 2 o 2 =3:1) soaked in 90min; then ultrasonically 15min with deionized water, and finally dried with an argon gun;

[0037] (2) Drug weighing and equipment debugging, use a high-precision electronic balanc...

Embodiment 3

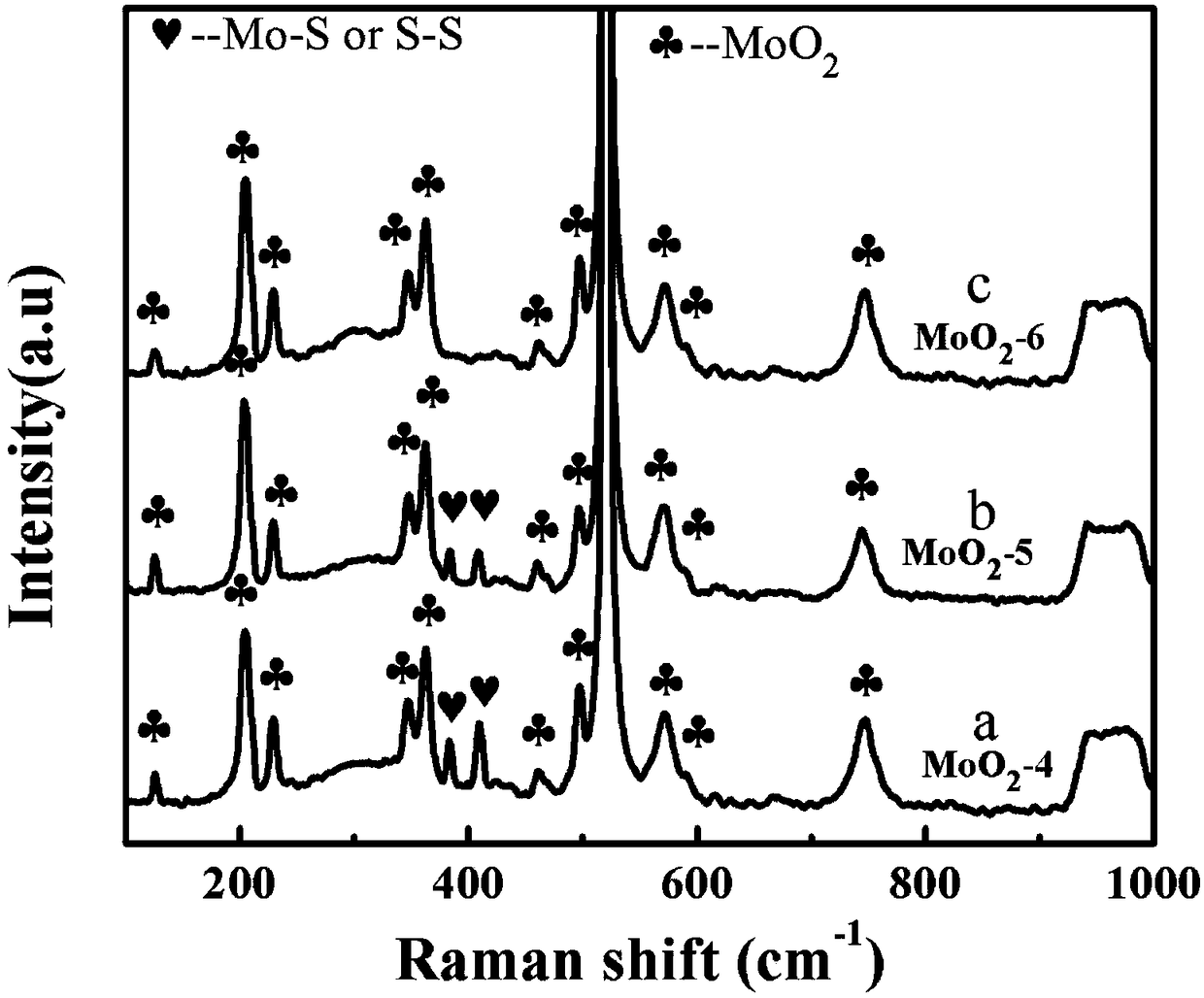

[0040] Through Examples 1 and 2, we prepared molybdenum dioxide nanosheets in three shapes: triangle, pentagon and rhombus under both conditions, and we measured their angles respectively. Such as image 3 As shown, a is MoO 2 -4 samples, b is MoO 2 -5 samples, c is MoO 2 -6 samples, the apex angles of triangles, pentagons and rhombuses are all 80°, and the adjacent angles on both sides of the apex angles of pentagons and rhombuses are all 100°, and there is also a 100° angle at the small angle of the triangle. Not obvious, where 80° and 100° are the angles of standard molybdenum dioxide monoclinic crystals, so we preliminarily judge that the main components of the three nanosheets are molybdenum dioxide, but the reaction process and growth rate are inconsistent, resulting in the formation of three shapes .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com