Electronically-controlled electric brake caliper assembly

A technology of electric braking and electronic control, applied in the direction of braking actuators, etc., can solve the problems of long reaction time, low braking energy efficiency, complicated device structure, etc., achieve high energy utilization rate, simple structure, and reduce energy The effect of the delivery path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

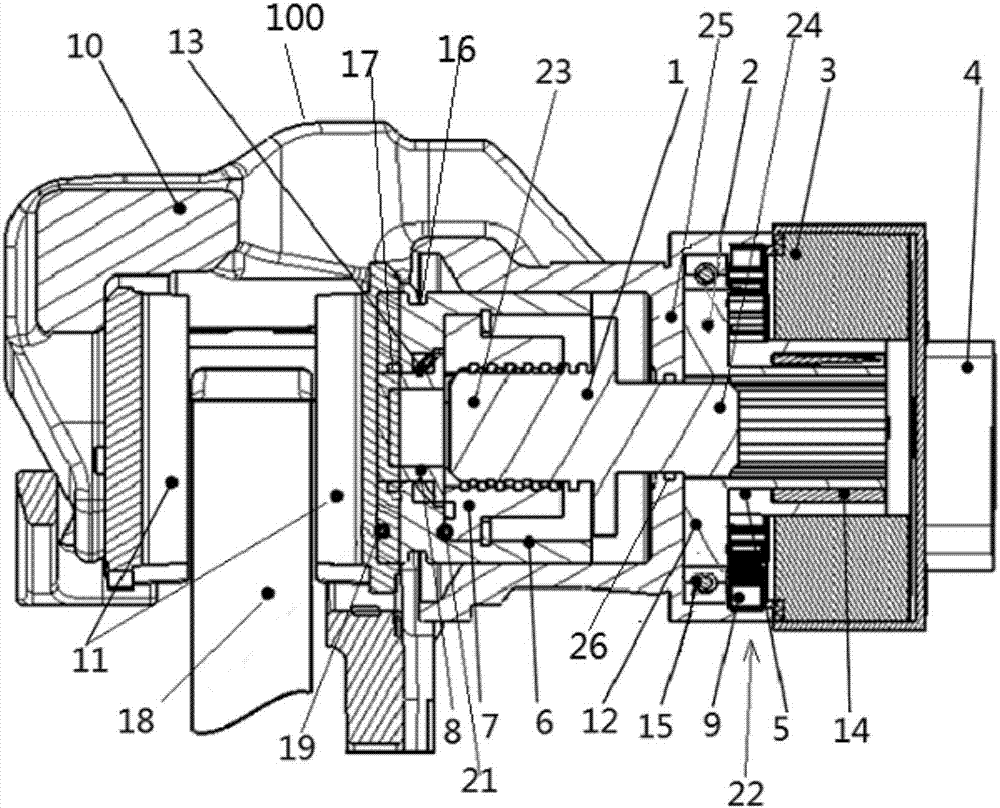

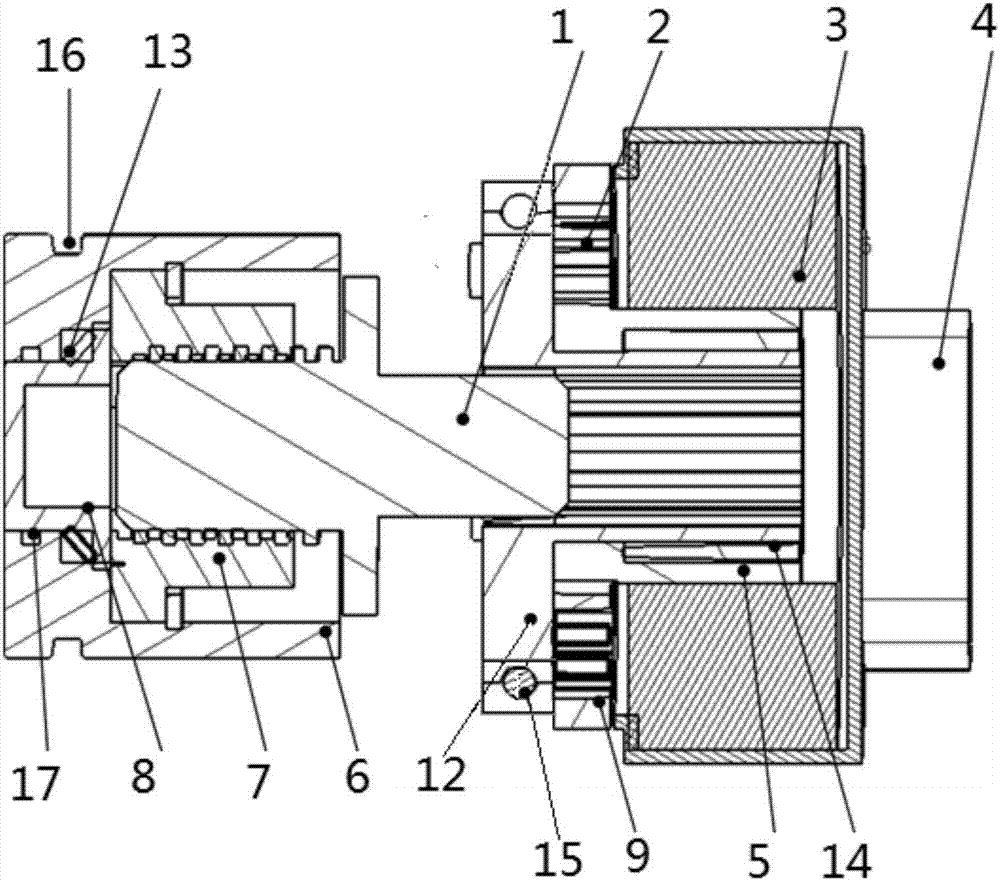

[0019] figure 1 It is a structural diagram of an electronically controlled electric brake caliper assembly according to an embodiment of the present invention. figure 2 It is a structure diagram of a motor planetary gear drive mechanism and a piston according to an embodiment of the present invention. combine figure 1 with figure 2 Do as follows. The electronically controlled electric brake caliper assembly includes a brake caliper 100 and a motor planetary gear drive mechanism 22 . Wherein the brake caliper 100 comprises a brake caliper body 10, a friction plate 11, a first piston 6, and a drive nut 7, wherein the friction plate 11, the first piston 6, and the drive nut 7 are assembled in the brake caliper body 10; The plates 11 are a pair and are arranged on both sides of the brake disc 18 for clamping the brake disc 18; the first end 19 of the first piston 6 abuts against one surface of the friction plate 11 to push the friction plate 11 Pressure; the second end 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com