Temperature sensor-free ultrasonic water meter temperature correction method

A temperature sensor-free, ultrasonic technology, applied in instruments, volume change compensation/correction devices, measurement devices, etc., can solve the problems of decreased measurement accuracy of ultrasonic water meters and low accuracy of temperature compensation, to expand the compatibility of use and improve measurement. Accuracy, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

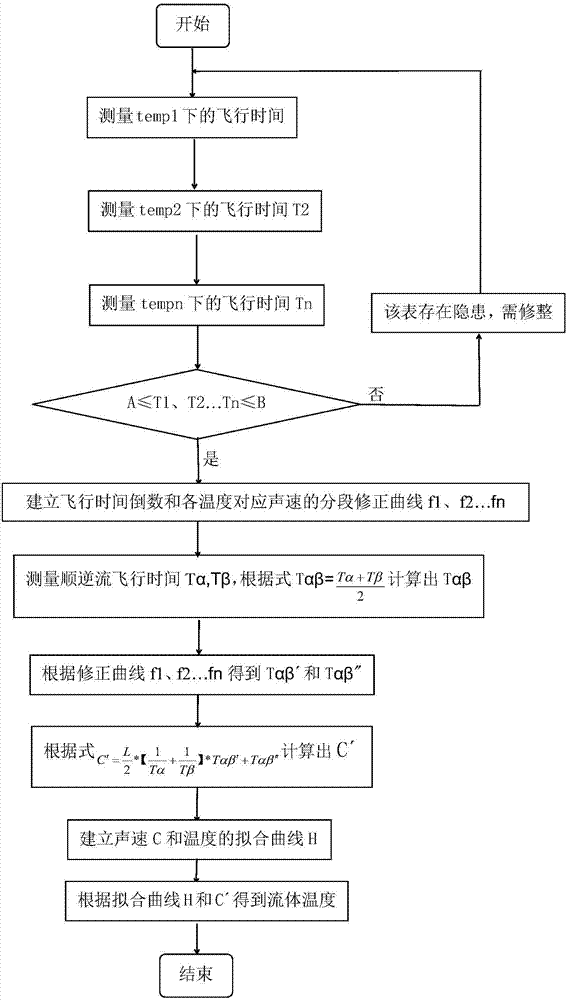

[0032] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0033] Such as figure 1 A kind of ultrasonic water meter temperature correction method without temperature sensor shown, comprises the following steps:

[0034] S1: Put the ultrasonic water meter on the flow detection platform, set the water flow in the pipe section of the ultrasonic water meter to be static and full, set the water temperature to a certain temperature of 5°C, 10°C...60°C, and measure the corresponding ultrasonic flight time T1, T2...Tn;

[0035] S2: Determine whether T1, T2...Tn is within the reasonable flight time A~B. If it is within this range, it proves that the overall performance of the watch is qualified, and then execute S3; if it is not within this range, it proves that there is a hidden danger in the watch. , for trimming;

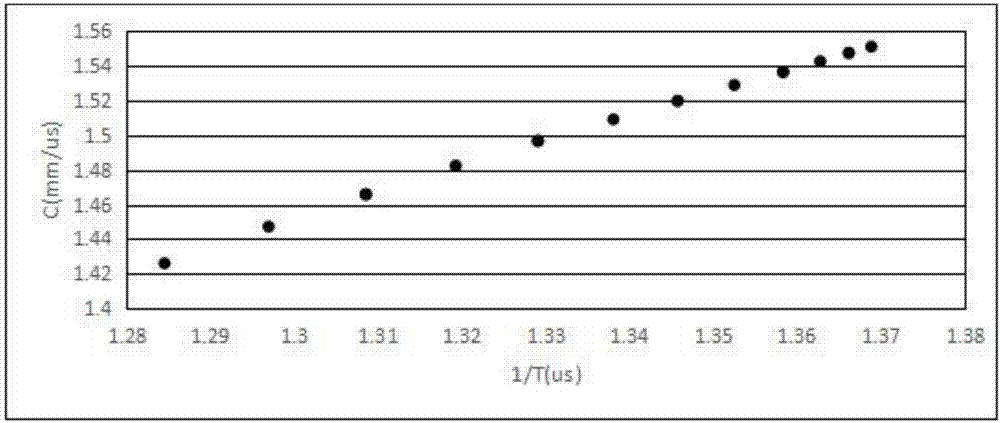

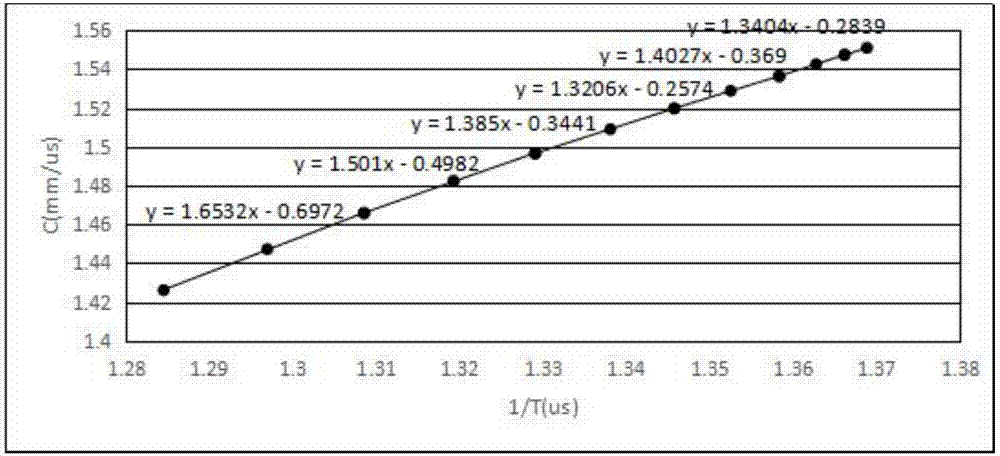

[0036] S3: According to the water sound speed C1, C2...Cn and flight time T1, T2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com