Method and device for quickly determining coal seam gas parameter for underground coal mine

A rapid measurement, coal seam gas technology, applied in the direction of analysis of materials, instruments, etc., can solve the problem that the measurement method cannot accurately measure the parameters of coal seam gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

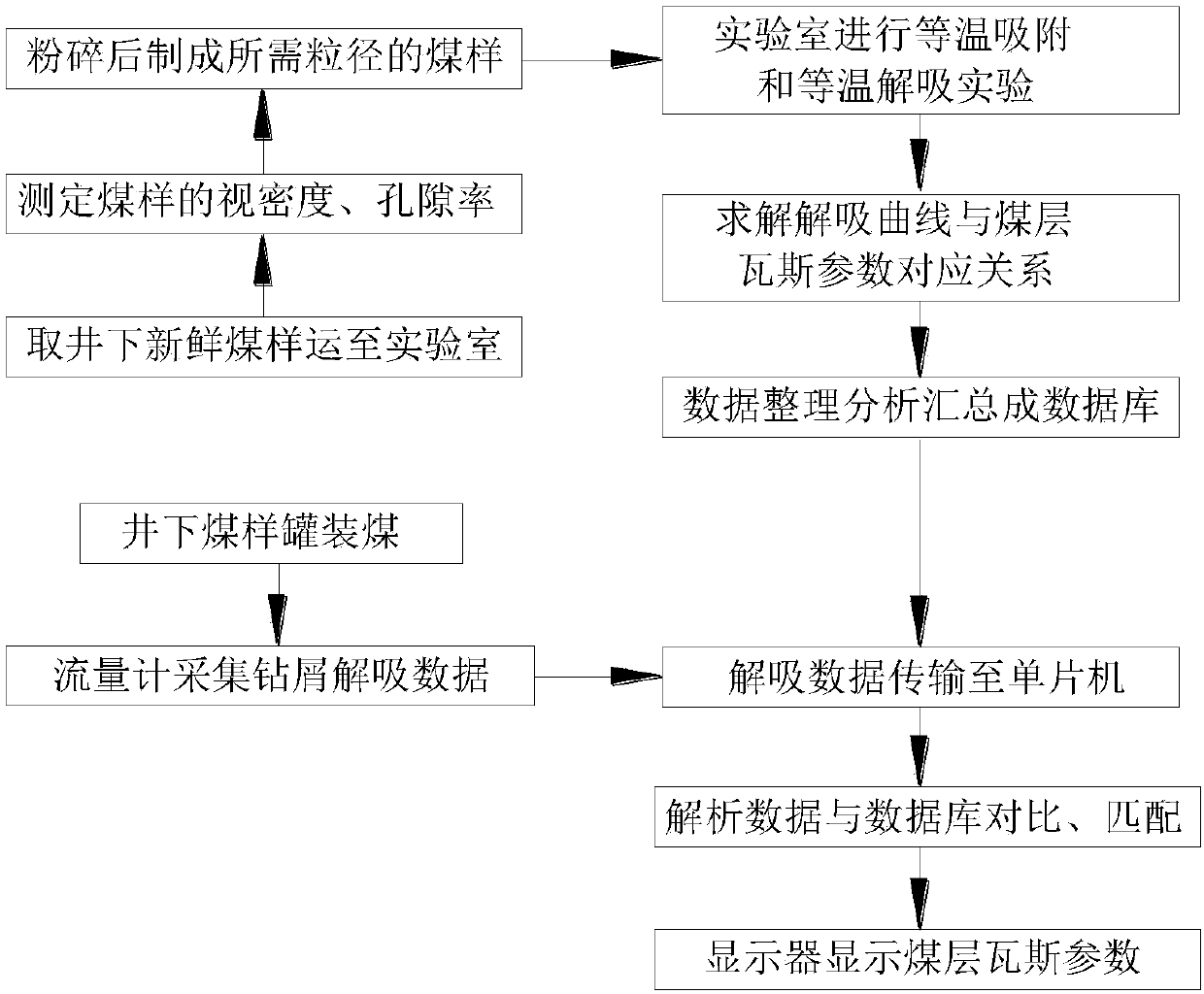

[0048] (1) Preparation and establishment of laboratory database

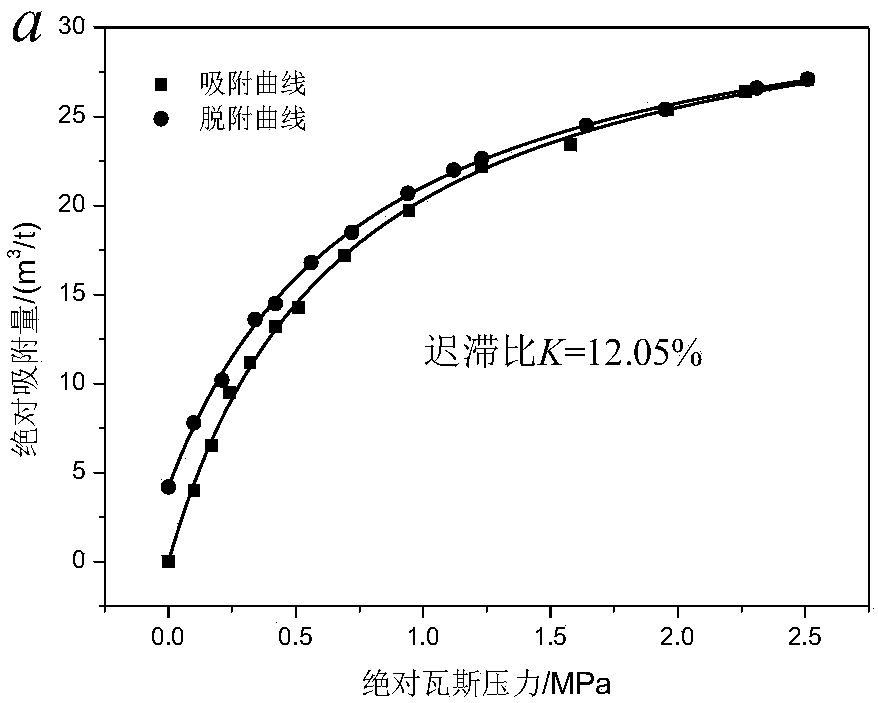

[0049] Take fresh coal samples and seal them and send them to the laboratory to measure the apparent density and porosity of the coal. At the same time, pulverize the coal samples according to the regulations and sieve the coal samples with a particle size of 1-3mm and put them into the coal sample tank, and then carry out 20 The isothermal adsorption experiment was carried out at ℃, and then the isothermal desorption experiment was carried out at 15℃, 20℃ and 25℃ respectively, and the desorption data of multiple groups of coal samples were summarized, and the desorption laws of the three temperatures were obtained respectively, and the temperature correction was carried out. , solve the corresponding relationship between the desorption curve and the gas parameters, and finally establish a database based on the conditions of fresh coal samples at 20°C and a particle size of 1 to 3 mm. range of parameters.

[00...

Embodiment 1

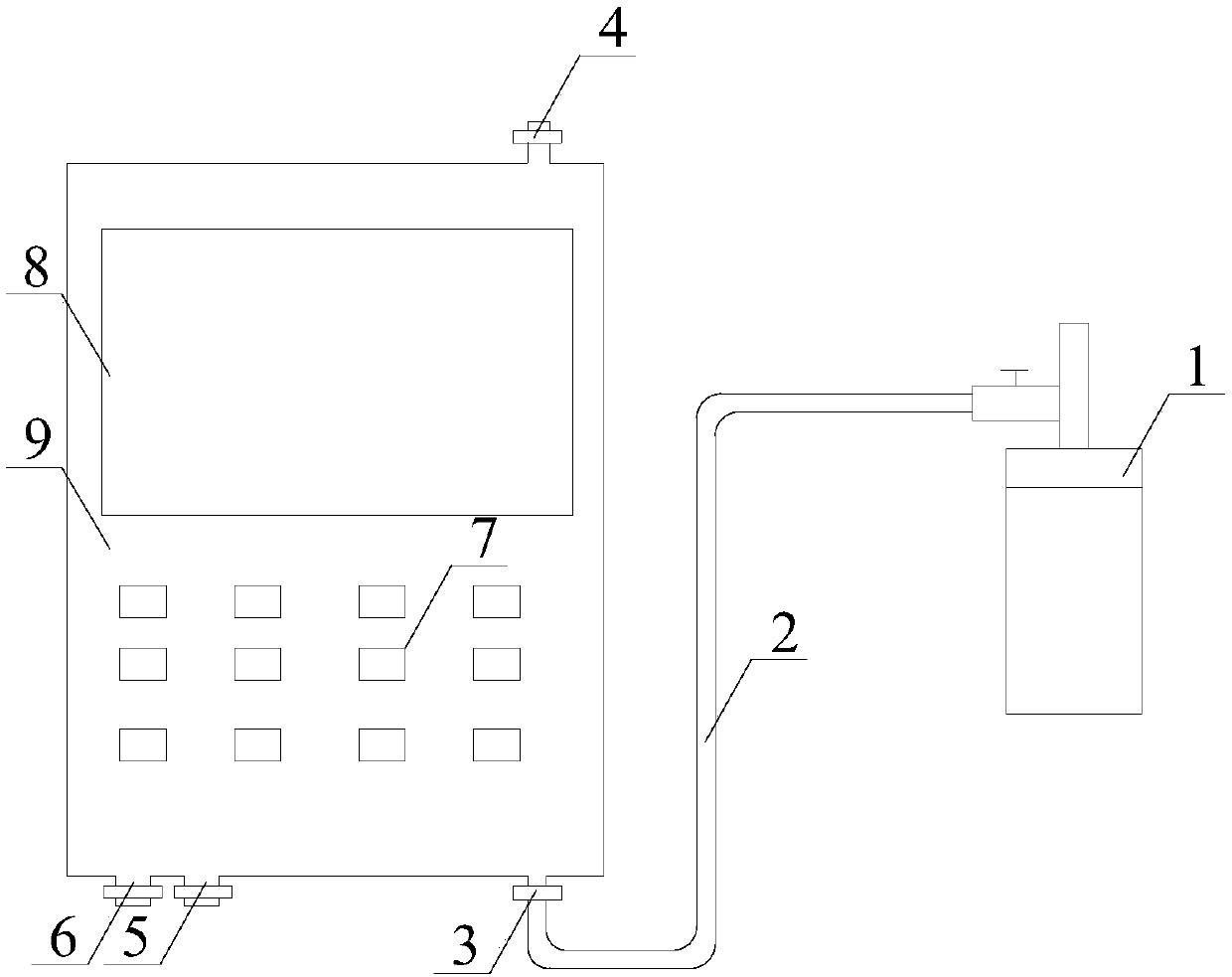

[0074] Embodiment 1: the measuring device is provided with a coal sample tank 1, a coal seam gas parameter rapid measuring instrument 9, and the coal sample tank 1 is connected with the air inlet 3 of the coal seam gas parameter rapid measuring instrument 9 through the air guide pipe 2, and the air inlet 3 Connect with one end of the flowmeter, which is used to collect the desorption data of drilling cuttings; the other end of the flowmeter is connected with the air outlet 4 through a hose, and at the same time connected with the single-chip microcomputer through a wire, and the collected desorption data is transmitted to the single-chip microcomputer and analysis; the single-chip microcomputer is provided with a data storage device for storage of database and desorption data; the display 8 is installed on the upper side of the single-chip microcomputer for real-time observation; the single-chip microcomputer is also connected with an intrinsically safe control circuit to provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com