Active material, non-aqueous electrolyte battery, battery pack and vehicle

A non-aqueous electrolyte and active material technology, applied in battery/fuel cell control devices, battery electrodes, secondary battery charging/discharging, etc., can solve problems such as difficulty in reducing electrode potential, achieve high energy density, excellent life performance, The effect of high rapid charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

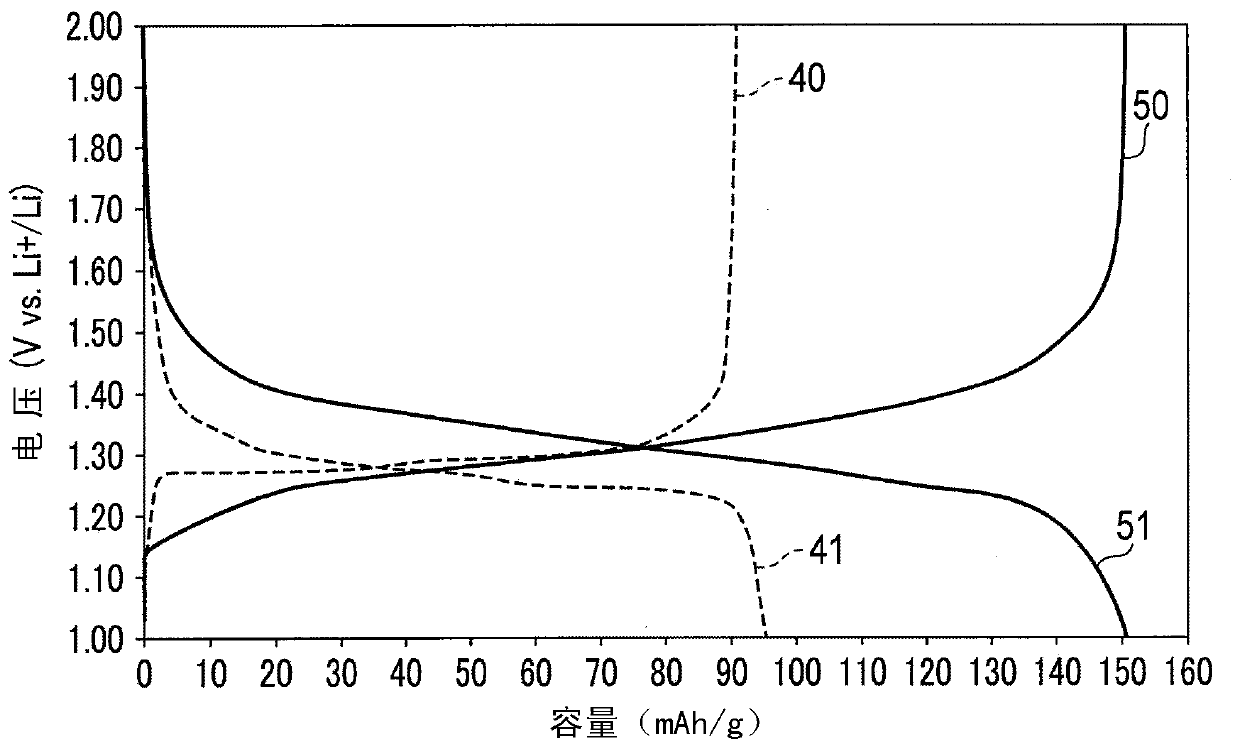

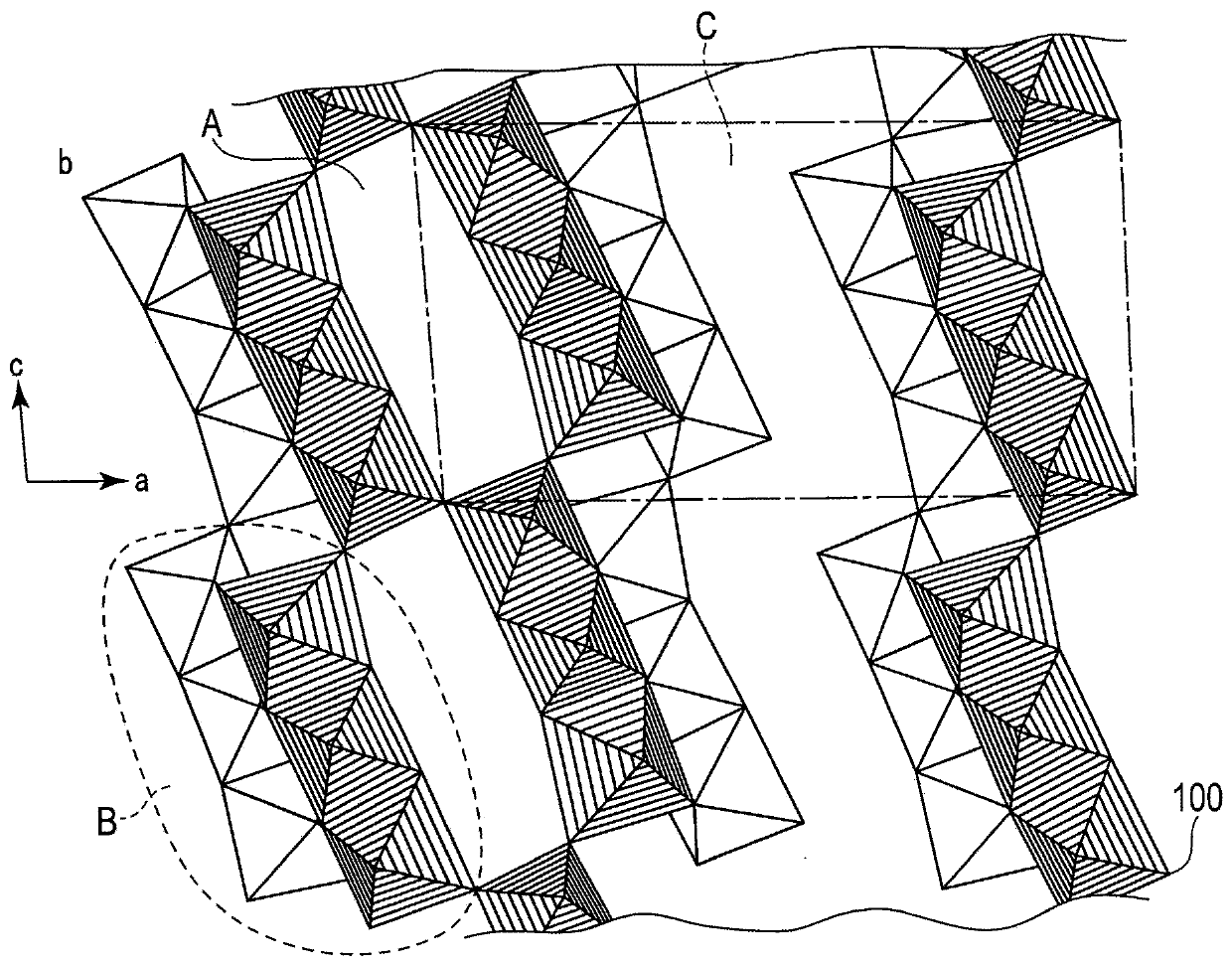

[0023] According to the first embodiment, there is provided an active material for batteries containing a composite oxide having a monoclinic crystal structure. The composite oxide has the general formula Li x M1 4-y Ti 10-z M2 2+z o 27+δ express. Here, M1 is at least one element selected from Na, K, and Cs. M2 is at least one element selected from Zr, Sn, V, Nb, Ta, Mo, W, Fe, Co, Mn, Ni, and Al. x is in the range of 0≦x<18. y is in the range of 0<y<4. z is in the range of 0<z<4. δ is in the range of -0.3≤δ≤0.3.

[0024] The composite oxide contained in the battery active material of the first embodiment may correspond to the compound oxide represented by the general formula Li x M1 4 Ti 10 M2 2 o 27+δ In the shown composite oxide having a monoclinic crystal structure, a vacancy site is introduced into a part of the M1 site, and at least a part of the Ti site is substituted with an M2 element. By changing the type or amount of the M1 element in the crystal stru...

no. 2 Embodiment approach

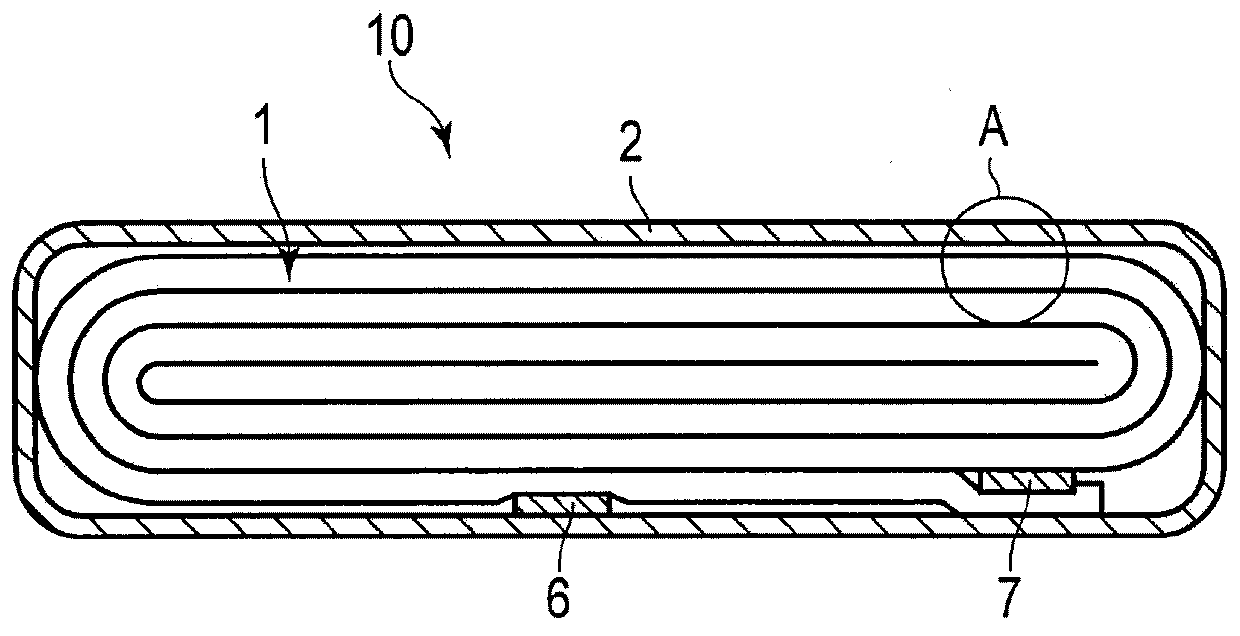

[0084] According to the second embodiment, a nonaqueous electrolyte battery is provided. This nonaqueous electrolyte battery includes a negative electrode containing the battery active material of the first embodiment, a positive electrode, and a nonaqueous electrolyte.

[0085] The non-aqueous electrolyte battery of the second embodiment may further include a separator disposed between the positive electrode and the negative electrode. The positive electrode, the negative electrode, and the separator can constitute an electrode group. A non-aqueous electrolyte may be held in the electrode group.

[0086] In addition, the non-aqueous electrolyte battery of the second embodiment may further include an exterior member for accommodating the electrode group and the non-aqueous electrolyte.

[0087] Furthermore, the non-aqueous electrolyte battery of the second embodiment may further include a positive terminal electrically connected to the positive electrode and a negative termi...

no. 3 Embodiment approach

[0152]According to the third embodiment, a battery pack is provided. This battery pack includes the nonaqueous electrolyte battery of the second embodiment.

[0153] The battery pack of the third embodiment may include one or more non-aqueous electrolyte batteries (single cells) of the second embodiment described above. When a plurality of cells are included, the cells are connected and arranged electrically in series or in parallel. Alternatively, a plurality of non-aqueous electrolyte batteries that may be included in the battery pack according to the third embodiment may be connected electrically in series or in parallel to form a battery pack. The battery pack of the third embodiment may also include a plurality of assembled batteries.

[0154] The battery pack of the third embodiment may further include a protection circuit. The protection circuit controls the charging and discharging of the non-aqueous electrolyte battery. Alternatively, a circuit included in a devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com