PWM rectifier with consideration of power quality control and controlling method thereof

A power quality and control method technology, applied in electrical components, circuit devices, AC network circuits, etc., can solve the problems of theoretical parameter and actual parameter errors, aperiodic interference signals are difficult to eradicate, difficult to eradicate, etc., to reduce fluctuations Influence and reduce the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

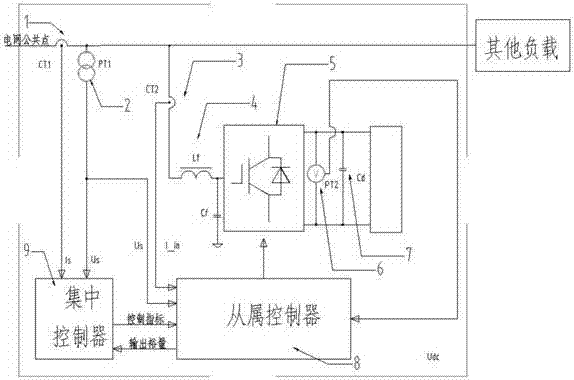

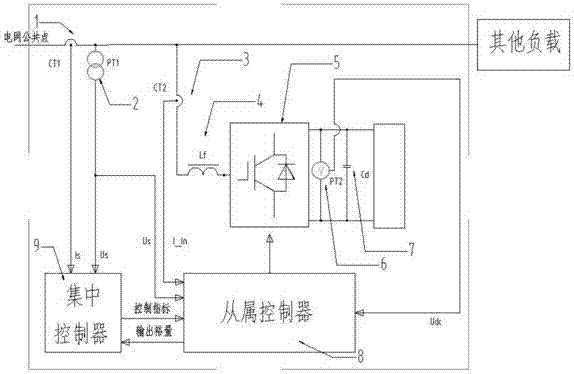

[0026] See figure 1 and figure 2 , the PWM rectifier of this embodiment has a set of rectifier main circuit and slave controller, specifically including: grid voltage sensor 1, grid current sensor 2, input current sensor 3, input filter 4, rectifier main circuit 5, output voltage sensor 6 , an output filter capacitor 7, a slave controller 8, and a centralized controller 9. in, figure 1 The input filter 4 shown is of the LC type, figure 2 The shown input filter 4 is L-shaped; the rectifier main circuit 5 adopts an H-bridge or any other type of rectifier with four-quadrant working capability. In order to be connected to a power grid with a higher voltage level, an AC transformer (not shown) may be installed at the front end of the PWM rectifier in this embodiment.

[0027] specifically,

[0028]The grid voltage sensor 1 and the grid current sensor 2 are coupled between the grid common point and the centralized controller 9, and the grid voltage sensor 1 and the grid curre...

Embodiment 2

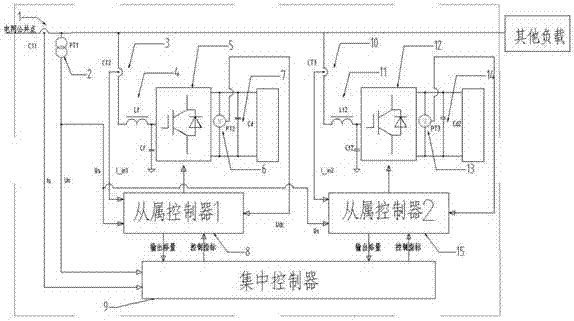

[0033] See image 3 and Figure 4 , the PWM rectifier of this embodiment has two sets of rectifier main circuits and slave controllers, specifically including: grid voltage sensor 1, grid current sensor 2, first input current sensor 3, first input filter 4, first rectifier main circuit 5. The first output voltage sensor 6, the first output filter capacitor 7, the first slave controller 8, the centralized controller 9, the second input current sensor 10, the second input filter 11, the second rectifier main circuit 12, the second Two output voltage sensors 13 , a second output filter capacitor 14 , and a second slave controller 15 . in, image 3 The first input filter 4 and the second input filter 11 shown are of LC type, Figure 4 The first input filter 4 and the second input filter 11 shown can also be L-type; the first rectifier main circuit 5 and the second rectifier main circuit 12 can also be H bridges or any other type with four-quadrant operation capability of the r...

Embodiment 3

[0037] This embodiment discloses a control method for a PWM rectifier. The PWM rectifier of the present invention has the following operating modes: outputting active power, or feeding back active power, or injecting reactive power and / or harmonics to the grid common point when outputting active power When suppressing or feeding back active power, reactive power and / or harmonic suppression are injected into the grid common point. The present invention is not limited to the application of the three-phase circuit, and the method of the present invention can also be implemented in a single-phase system by constructing a three-phase circuit signal and the like.

[0038] The control method of the PWM rectifier comprises the following steps:

[0039] 1) The slave controller judges whether the grid needs active power feedback. If not, the PWM rectifier enters the energy absorption mode to absorb the grid active power and provide energy to the DC side. At the same time, the slave cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com