Stator provided with metal support framework

A metal support and skeleton technology, applied in the field of micro motors, can solve the problems of difficult to ensure that the bearing installation position is strictly coaxial, unstable operation of the micro motor, and high failure rate, and achieve the effects of small vibration, avoidance of stability, and low failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

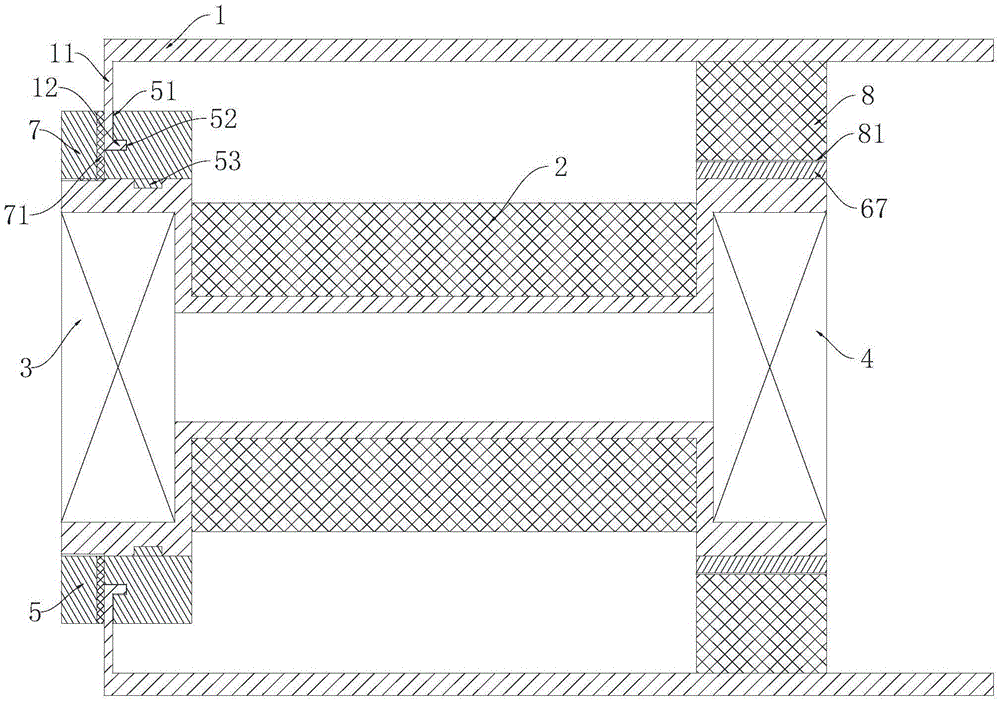

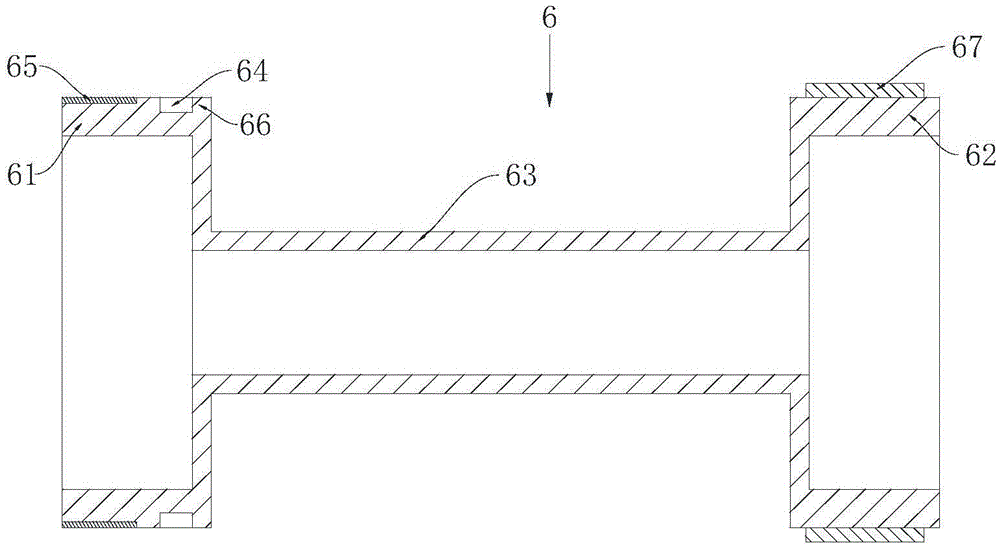

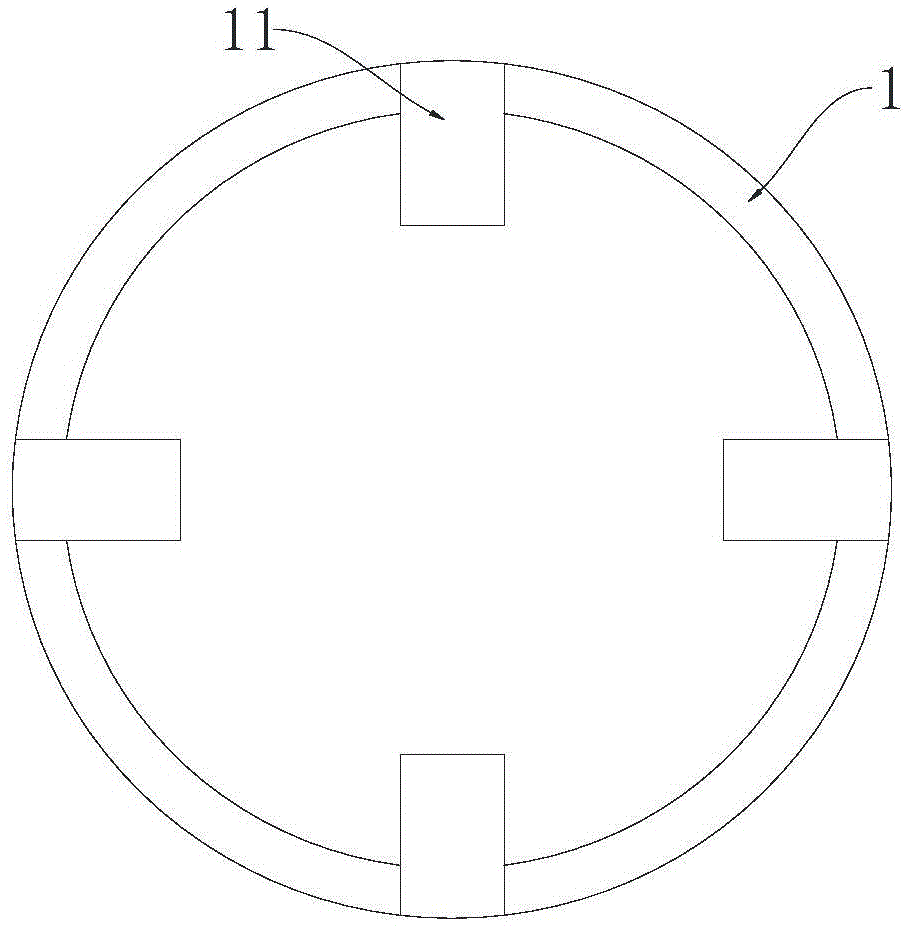

[0028] Such as Figure 1 to Figure 3 As shown, the stator provided with a metal support frame includes a housing 1 and a hollow and integrally formed metal support frame 6;

[0029] The metal support frame 6 includes a magnetic steel accommodation section 63, a first bearing accommodation section 61 located at the front end of the magnetic steel accommodation section 63 and coaxially arranged with the magnetic steel accommodation section 63, and a first bearing accommodation section 61 located at the rear end of the magnetic steel accommodation section 63 and connected to the magnetic steel accommodation section. 63 The second bearing containing section 62 coaxially arranged, the outer wall of the magnetic steel containing section 63 is inlaid with the magnetic steel 2, the front bearing 3 is fixed in the first bearing containing section 61, and the rear bearing 4 is fixed in the second bearing containing section 62 , the outer wall of the first bearing receiving section 61 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com