A Low Commutation Torque Pulse Brushless DC Motor

A brushed DC motor, DC motor technology, applied in electromechanical devices, electrical components, etc., can solve the problem of large commutation torque ripple, reduce noise and vibration, reduce electromagnetic commutation torque ripple, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

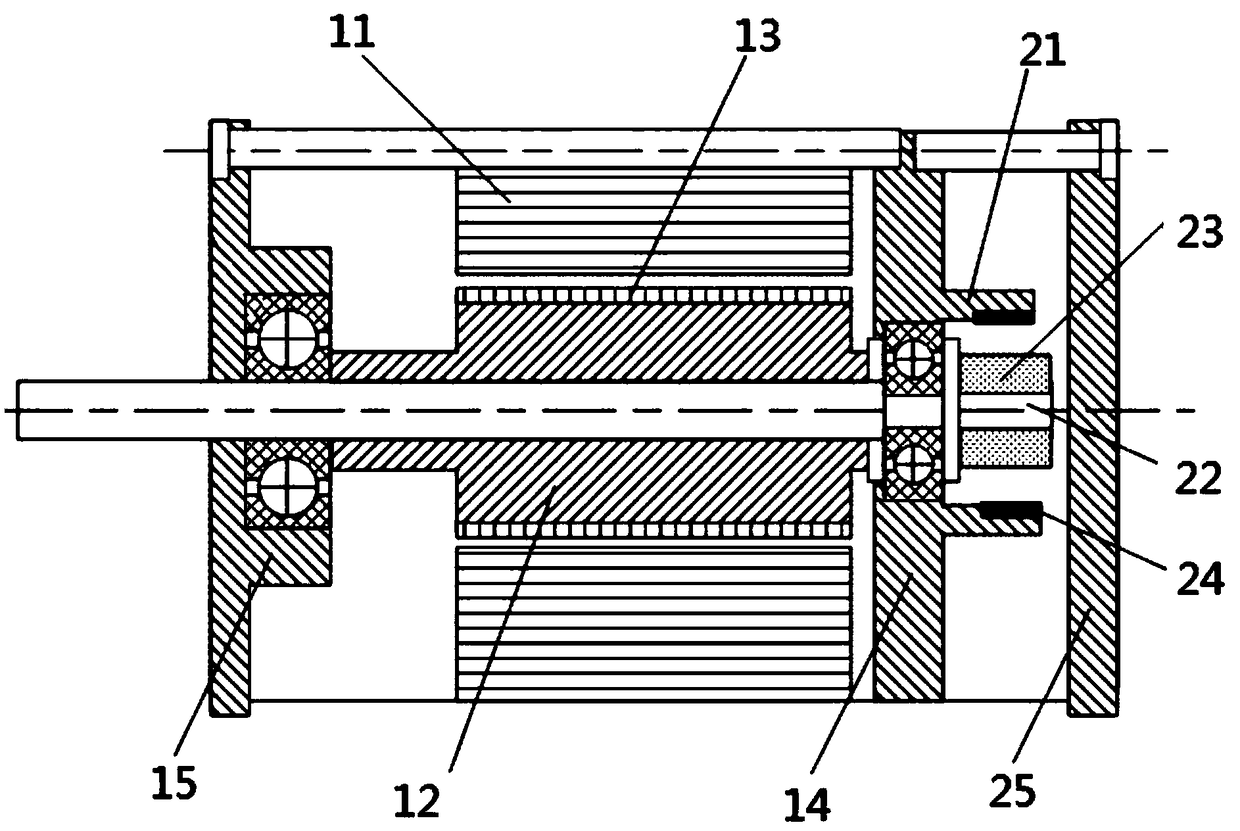

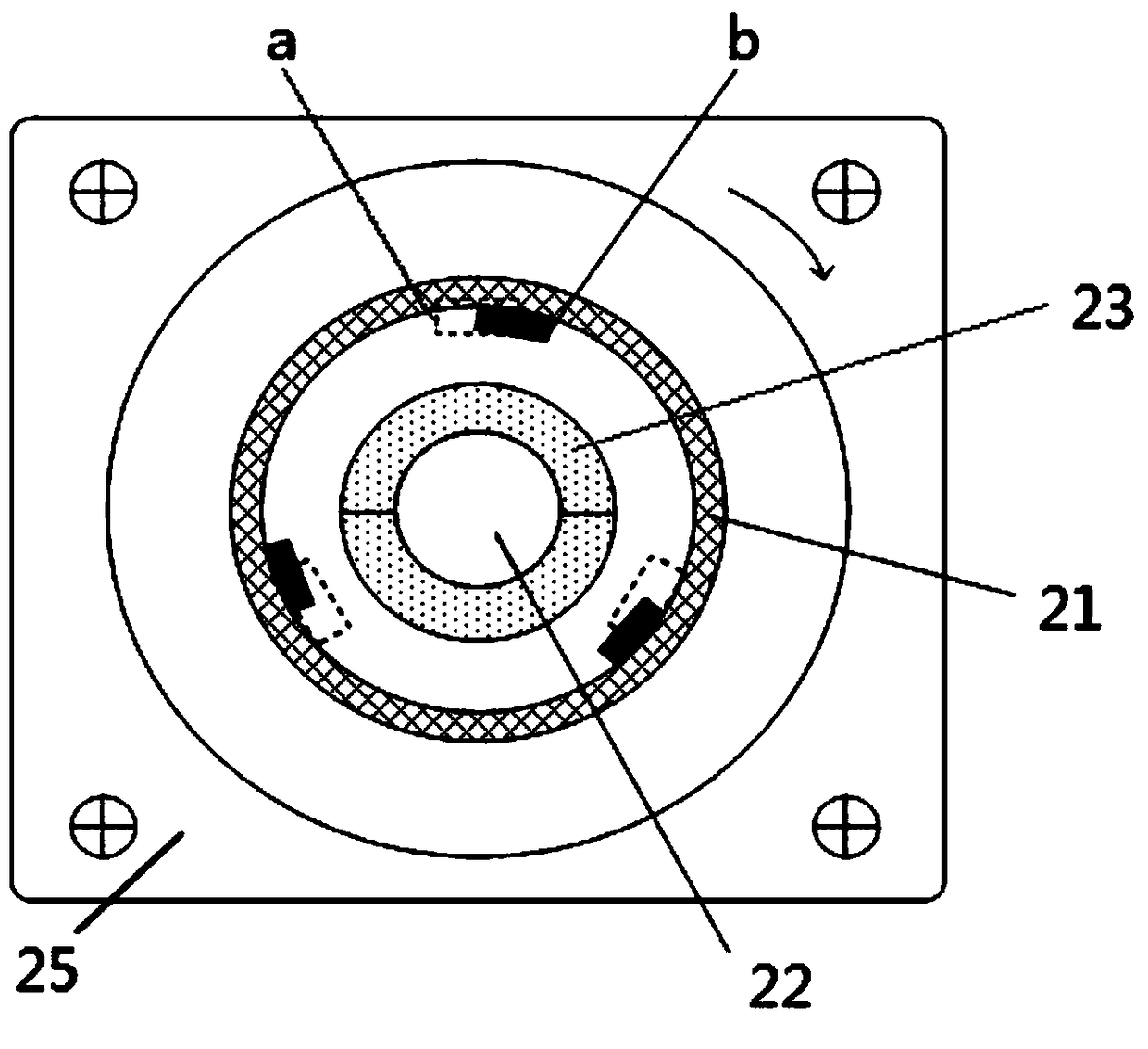

[0036] figure 1 It is a structural sectional view of an embodiment of the low-commutation torque pulsating brushless DC motor of the present invention. figure 2 It is a schematic diagram of the cross-sectional structure of the sensor device of the present invention.

[0037] see figure 1 and figure 2 As shown, in the embodiment of the present invention, the DC brushless motor includes a DC motor and a sensor device.

[0038] The DC motor includes a first stator 11, a first rotor 12, a first rotor magnetic steel 13 and a rear end cover 14; the first stator 11 is coaxially corresponding to the first rotor 12, and the first rotor The magnetic steel 13 is mounted on the outer ring of the first rotor 12 .

[0039] The sensor device includes a second stator 21, a second rotor 22, an annular magnet 23 and a sensor integrated circuit;

[0040] The second stator 21 is ring-shaped, fixed on the rear cover 14 and arranged corresponding to the first rotor 12 , and the second rotor ...

Embodiment 2

[0046] The overall structure of the brushless DC motor in Embodiment 2 of the present invention is similar to Embodiment 1, and a position sensor device is added outside the rear end cover of the DC motor.

[0047] In the second embodiment, the hysteresis installation position b is moved positively by 10° from the optimal commutation position a along the rotation direction of the second rotor.

[0048] The ring magnet 23 is a ring magnet having the same number of pole pairs as the first rotor magnet 13 .

[0049] The position sensor is a Hall sensor, and the marking surface of the Hall sensor points to the rotation axis of the second rotor.

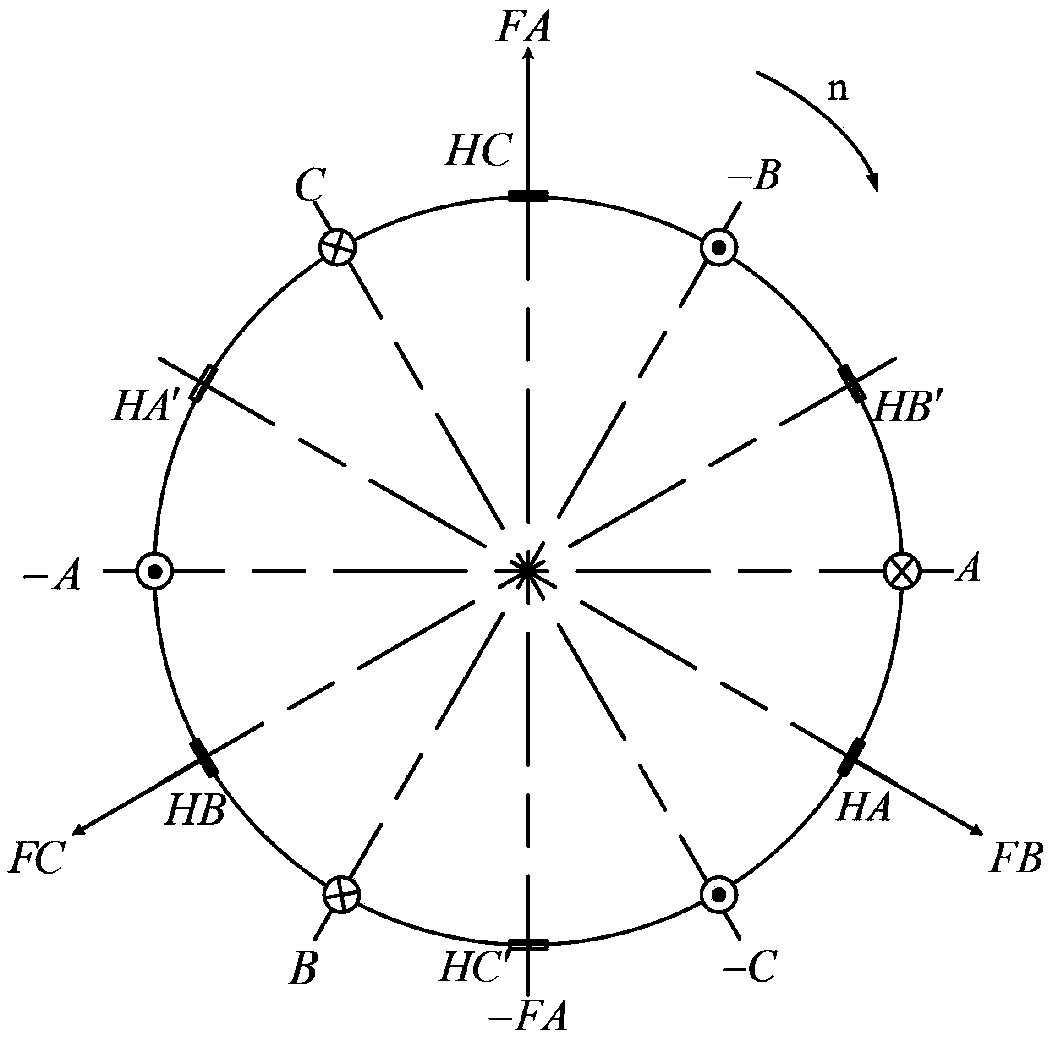

[0050] The embodiment of the present invention adopts the method of placing the position sensor externally, so that the first rotor and the second rotor rotate coaxially and synchronously. Under the three-phase full-wave six-state working mode of the motor, two groups of six Hall sensors can be found on the inner surface of the second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com