A food system with high energy utilization rate

A technology with high utilization rate and high energy, which is applied in the field of food system with high energy utilization rate, can solve the problems of low energy utilization rate, complex structure, high cost, etc., and achieve the effect of good heating and drying effect, high energy utilization rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in conjunction with the following examples.

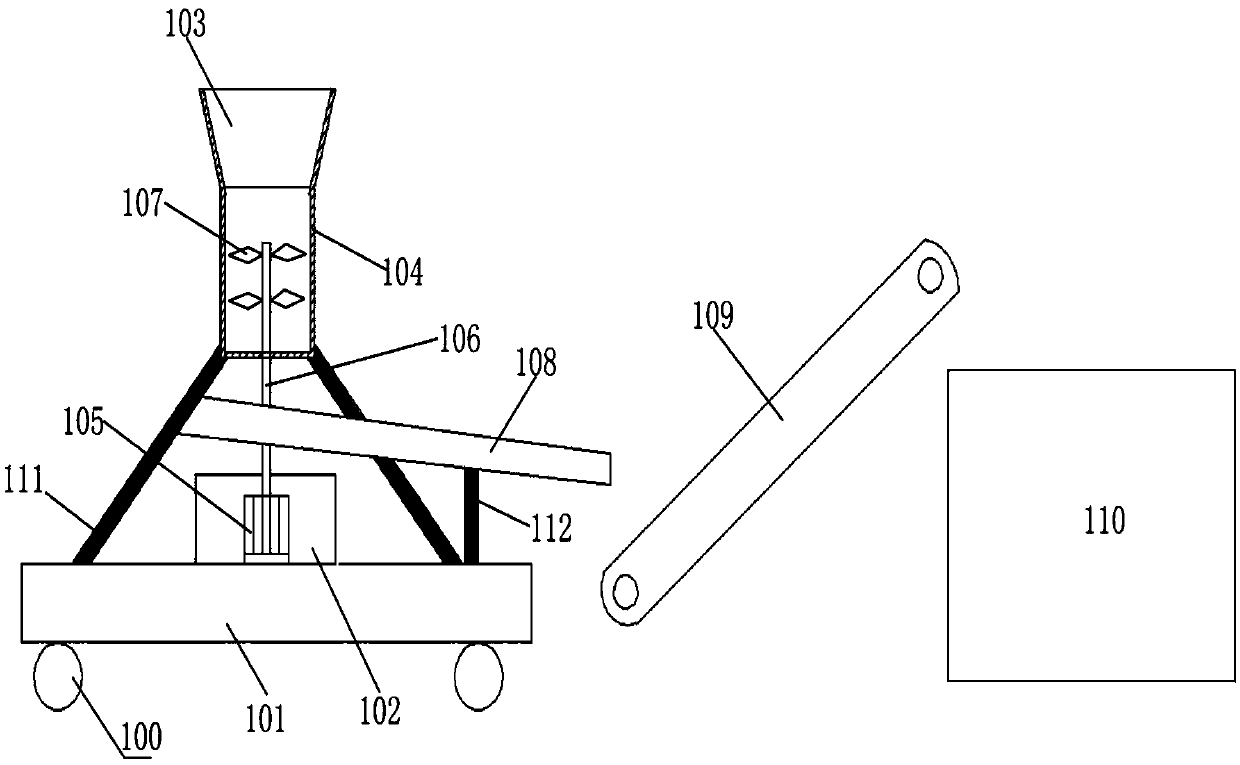

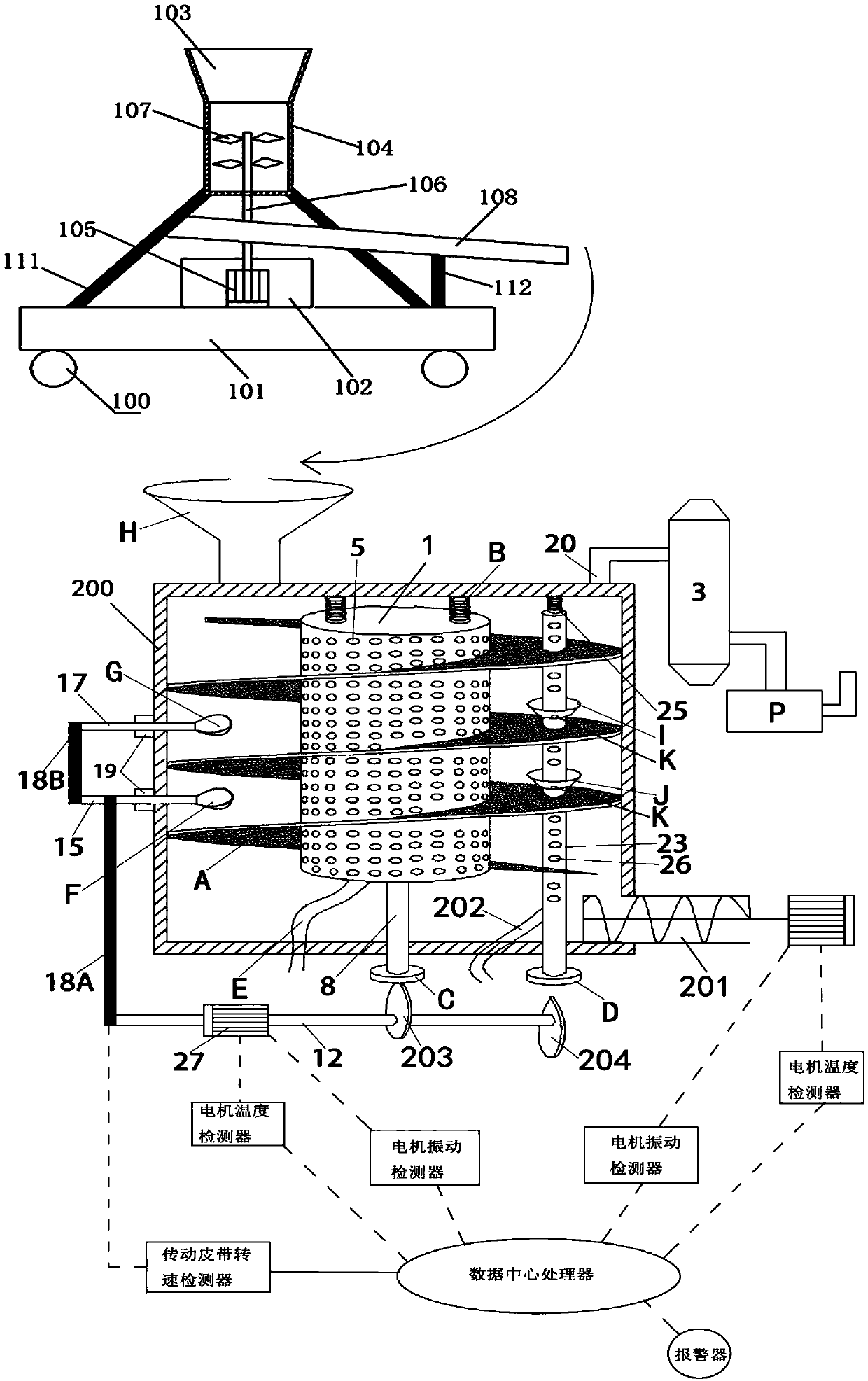

[0011] See as Figure 1-2 A food system with a high energy utilization rate shown includes a bottom plate 101 with a roller 100 at the bottom, a motor box 102 set on the bottom plate 101, a crusher food material input hopper 103, a crusher food material input hopper 103 and a crushing drum The rotating shaft 106 driven by the motor 105 in the motor box 102 is fixedly connected with a plurality of stirring knives 107. The lower end of the crushing cylinder 104 is open, and the crushed food materials fall into the crushing cylinder 104 and the motor box 102. The food material in the discharge sloping hopper 108 is conveyed to the food material heating and drying device 110 through the conveying belt 109 for heating.

[0012] As a further preferred solution, the crushing cylinder 104 is fixed to the bottom plate 101 through two legs 111. The food raw material heating and drying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com