Coating device for spraying for petroleum casing pipe

A technology for coating device and oil casing, applied in the direction of injection device, etc., can solve the problems of impurity integration and affecting the quality of casing coating layer, and achieve the effect of improving quality, removing potential safety hazards and protecting physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

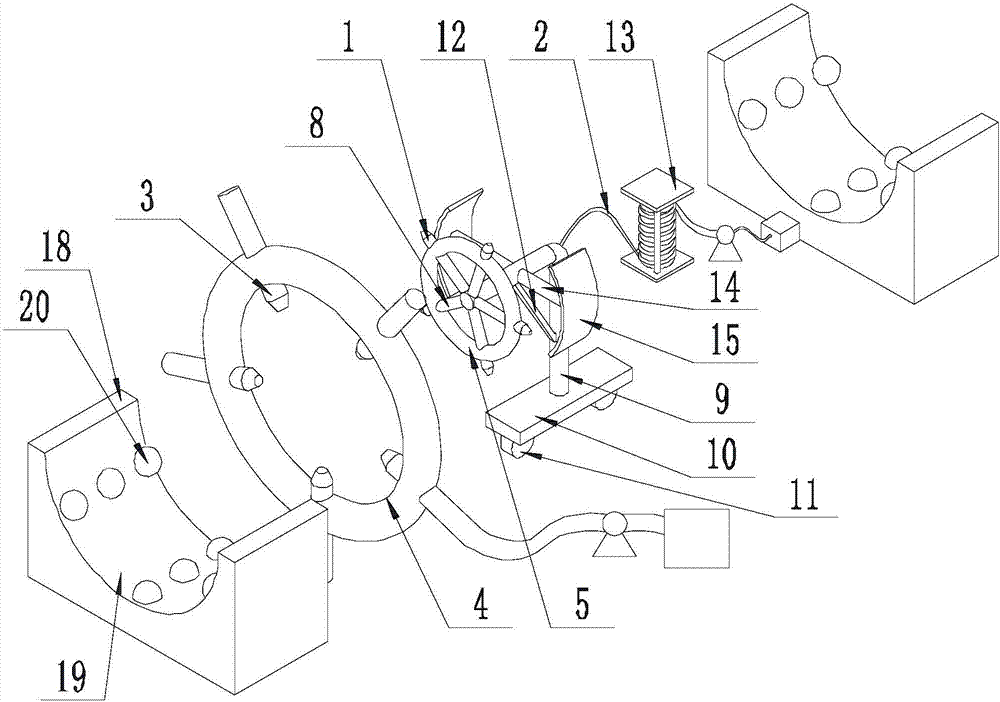

[0039] Such as Figure 1-Figure 4 As shown, the coating device for spraying petroleum casing in the present invention includes nozzle I1, nozzle II3, delivery pipeline 2, pump and paint storage tank, and said nozzle I1 and nozzle II3 respectively pass through a delivery pipeline 2 and pump Connected, the pump sends the paint in the paint storage tank into the delivery pipeline 2, and a spray ring 5, a supporting device and a driving device are arranged between the nozzle I1 and the delivery pipeline 2 connected to it;

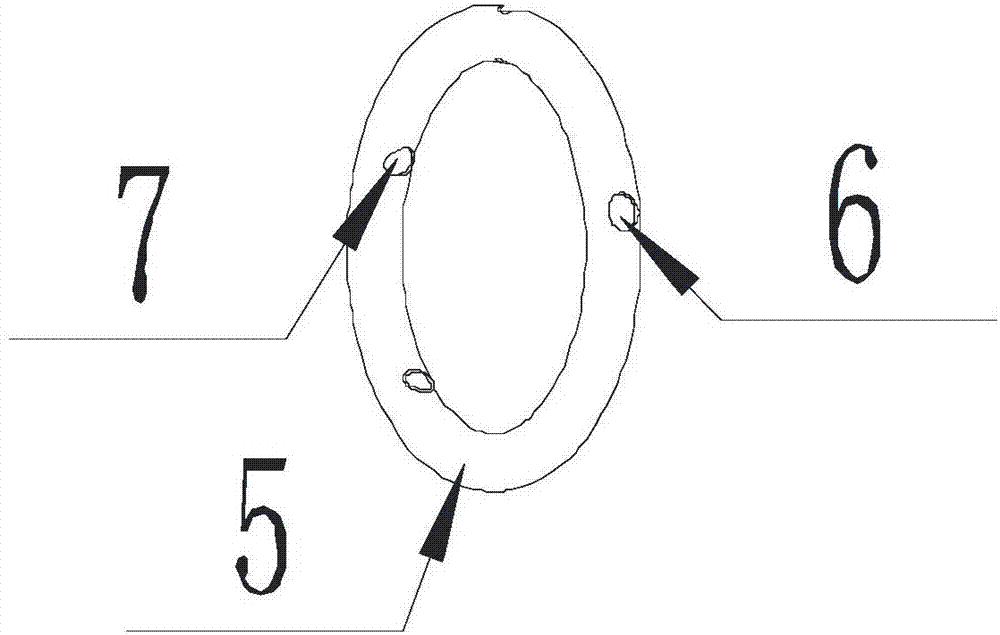

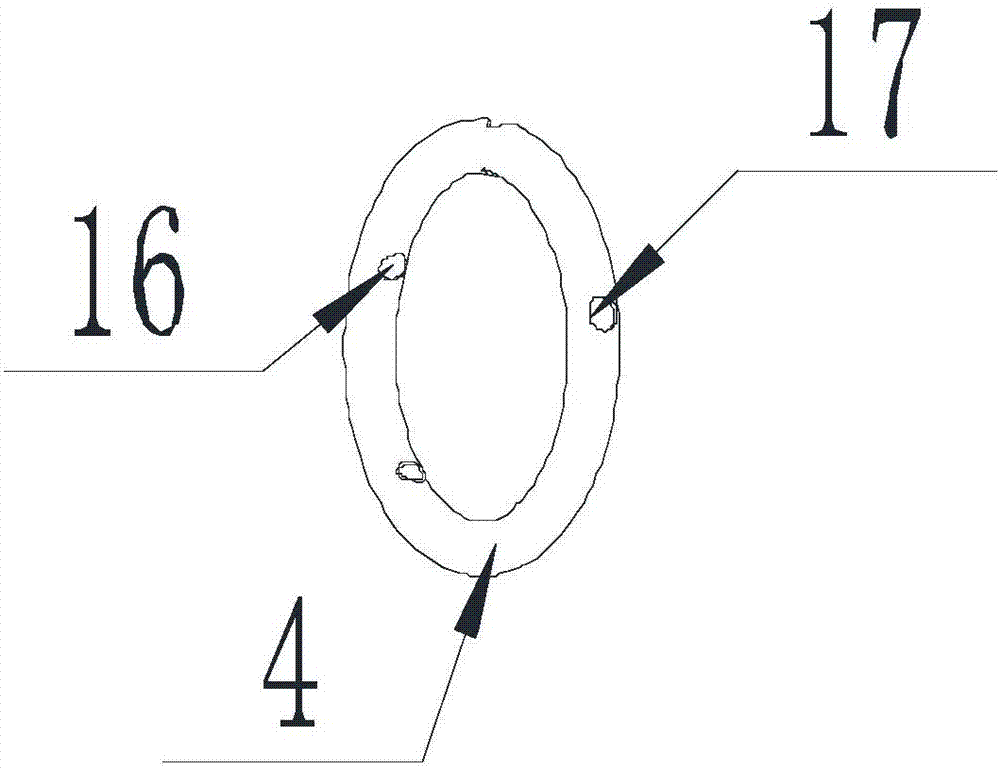

[0040] The spray ring 5 is hollow, and a spray hole I6 is provided on the outer surface of the spray ring 5. The spray hole I6 communicates with the hollow of the spray ring 5, and the liquid inlet end of the nozzle I1 is far away from the hollow of the spray hole I6. One end of the pump is connected; the inner surface of the spray ring 5 is provided with a paint inlet hole I7, the paint inlet hole I7 communicates with the hollow of the spray ring 5, and the en...

Embodiment 2

[0045] The present invention is based on embodiment 1, and the present invention is further described.

[0046] Such as Figure 1-Figure 4 As shown, the coating device for spraying petroleum casing in the present invention also includes a paint inlet pipe 8, and the delivery pipeline 2 communicates with the paint inlet hole I7 through the paint inlet pipe 8; the support device includes a support rod 9 and a support Plate 10, the support rod 9 is an L-shaped rod, one end of which is connected to the end of the paint inlet pipe 8 side away from the paint inlet I7, and the other end is connected vertically to the support plate 10; the driving device includes rollers 11 and The motor, the roller 11 is an end away from the support rod 9 on the support plate 10, the motor drives the roller 11 to rotate and drives the support device to move.

[0047] Further, a reinforcing rib 12 is provided on the supporting rod 9 , the reinforcing rib 12 is connected to one side of the supporting ...

Embodiment 3

[0052] The present invention is based on embodiment 1, and the present invention is further described.

[0053] Such as Figure 1-Figure 4 As shown, the coating device for spraying oil casing in the present invention also includes a winding device 13 for winding the delivery pipeline 2 between the pump and the spray ring 5 . As the spraying operation progresses, the entire device continuously moves to the oil casing mouth, and shortens the distance between the spray ring 5 and the pump 3, so the redundant delivery pipeline 2 between the spray ring 5 and the pump 3 is connected to Gather and wrap up. The winding device can choose the existing device for winding electric wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com