Fresh tea winnowing machine for tea production

A kind of winnowing machine and fresh leaf technology, which is applied in the direction of separating solids from solids by air flow, solid separation, filtering and sieving, etc. It can solve the problems of five-stage fresh leaf classification, poor fluidity, and high water content in fresh tea leaves and other problems, to achieve the effect of easy operation, suitable for popularization and application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

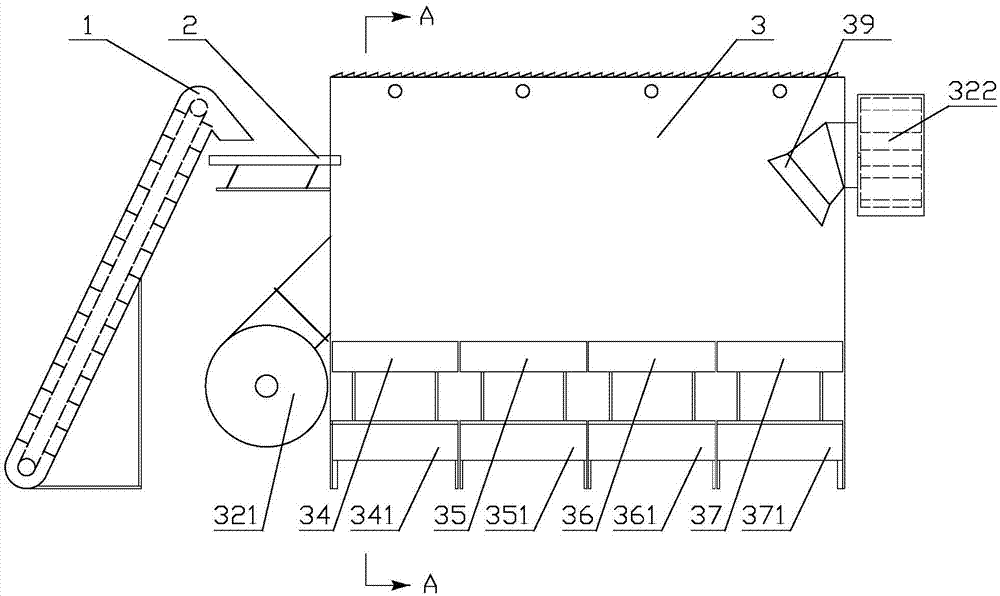

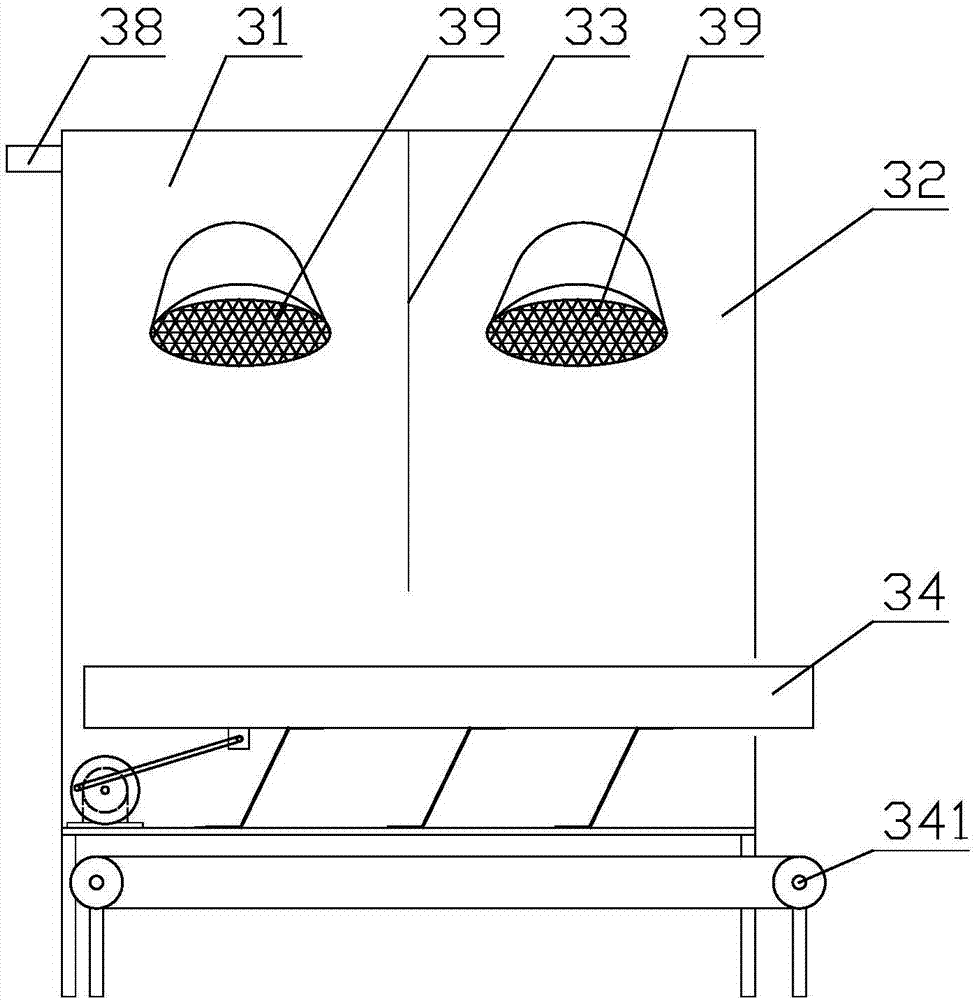

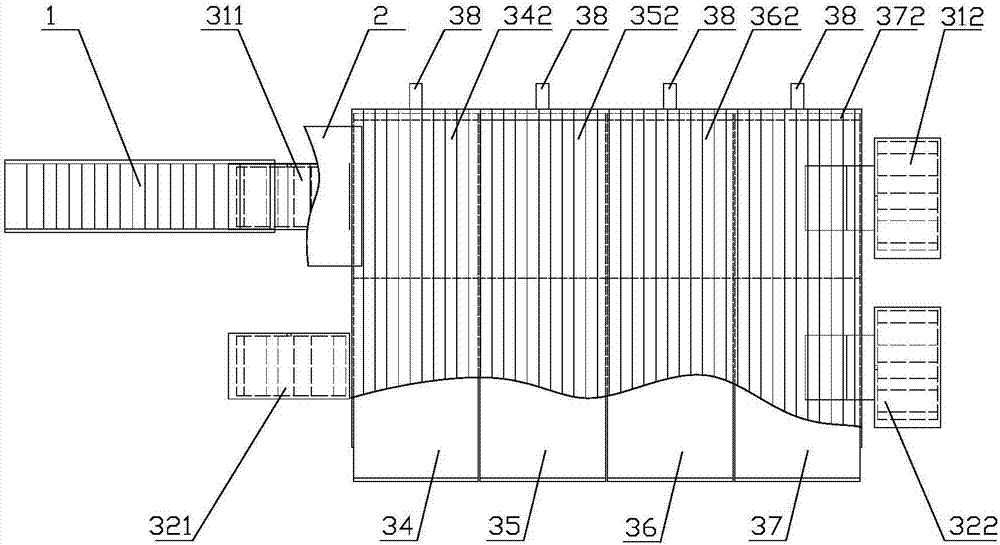

[0032] see Figure 1 to Figure 5 , a fresh leaf winnowing machine for making tea, comprising a hoist 1, a vibrating feeder 2, and a winnowing chamber 3. The winnowing chamber 3 is a cuboid box-shaped structure, the front and rear are the length direction, and the left and right are the width direction. There are front side panels, rear side panels, left side panels, and right side panels. The top is provided with louvers, and the bottom is provided with vibrating screens. , a conveyor belt is provided below the vibrating screen.

[0033] A vertical dividing plate 33 is arranged on the lower side of the shutter, the upper end of the dividing plate 33 is close to the blind, and the front and rear ends of the dividing plate 33 are respectively connected with the middle position of the width direction of the front side plate and the rear side plate , the winnowing chamber 3 is divided into two winnowing chambers, the left side is the first winnowing chamber 31, the right side is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com