A Local Springback Compensation Method of Die Surface Based on Ellipse Surface Mapping Drive

A technology of mold profile and springback compensation, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of partial size of parts not meeting tolerance requirements, poor surface quality, and inability to use molds to manufacture, etc. Improve the efficiency of local springback compensation, reduce the amount of training, and shorten the mold manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

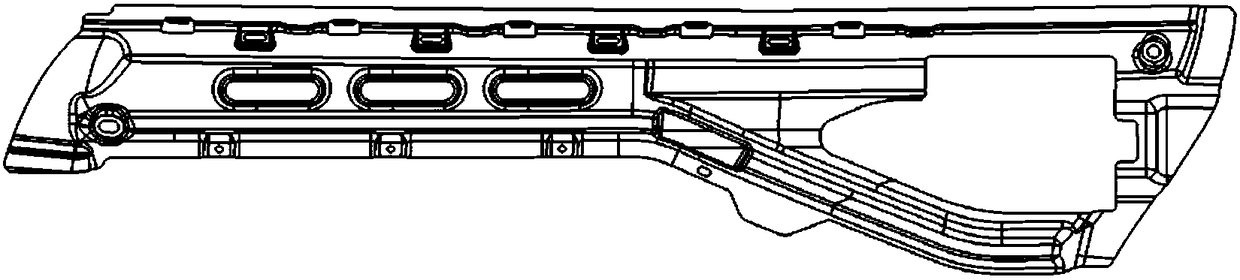

[0049] The product model of the side wall and rear reinforcement plate of a certain car model is as follows: Figure 4 As shown, the product is a left-right symmetrical piece, and the stamping process is designed as one mold and two pieces. In order to evaluate the dimensional accuracy of the product, the simulation is carried out in the AutoForm simulation software according to the content of the stamping process. Figure 5 Shown is the springback distribution cloud map of the product. The springback result shows that the local springback value of the product exceeds the tolerance range. The tolerance requirement is ±0.5mm. Springback compensation is required. The steps are as follows:

[0050] The first step is to obtain the cloud map of the local springback distribution of the part, and the sub-steps are:

[0051] ① Export the springback parts from AutoForm software in stl file format;

[0052] ② Import the stl file into the Digitized Shape Editor module of CATIA software,...

Embodiment 2

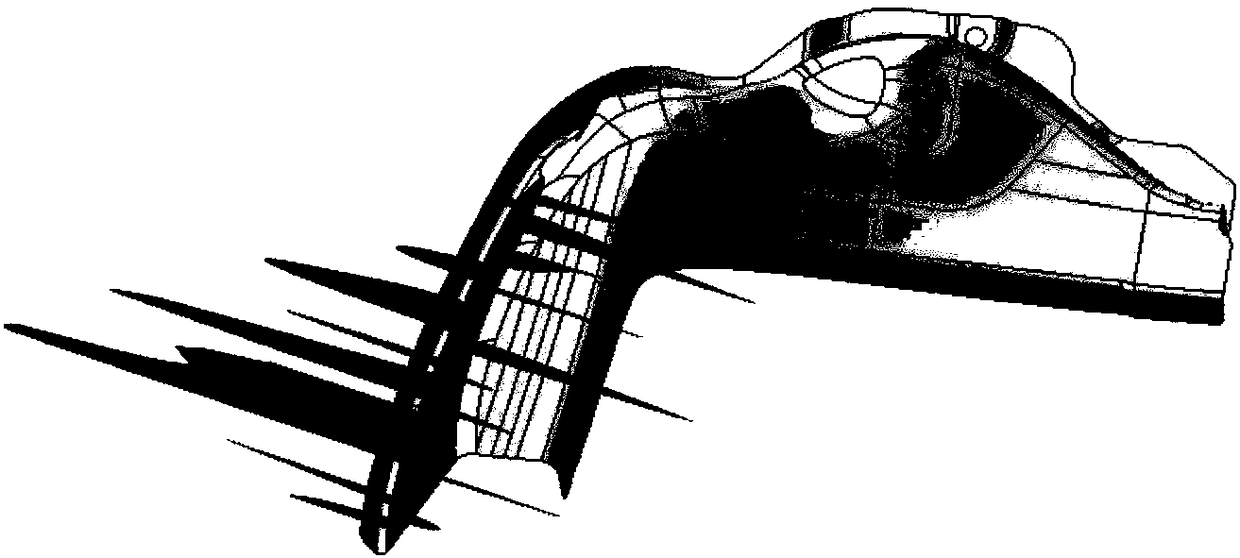

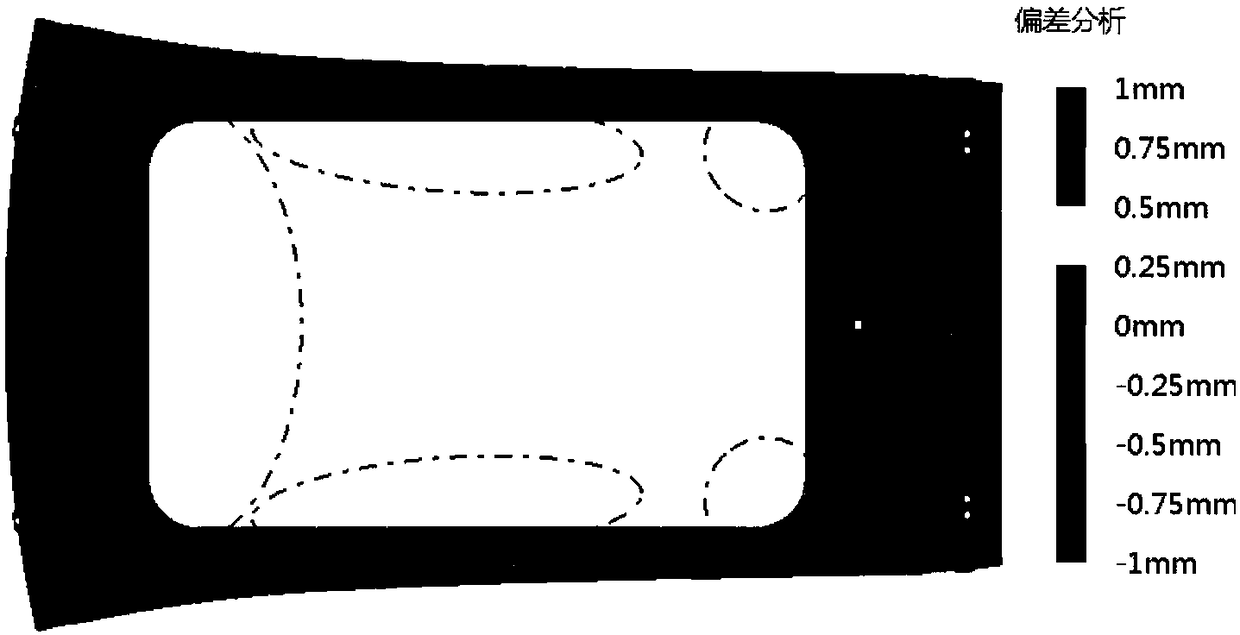

[0072] Figure 14 Shown is the product model of the door reinforcement plate of a certain car model. The product is a left-right symmetrical part. The stamping process is designed as one mold and two pieces. The stamping of the product is completed by using a 3-sequence mold. After the mold is qualified, the first round of stamping test is carried out. Figure 15 As shown, the optical inspection found that the local size of the trial punched part exceeded the tolerance range, and it is necessary to perform springback compensation on the surface of the current drawing convex model. The following takes the negative springback area at the end of the part as an example to perform local springback compensation. The steps are as follows :

[0073] The first step is to obtain the cloud map of the local springback distribution of the part, and the sub-steps are:

[0074] ① Export the point cloud data obtained by optical inspection in stl file format;

[0075] ②Import the stl file in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com