Multi-stage series mobile power supply system

A technology of mobile power supply and power supply system, applied in the direction of collectors, electric vehicles, electric traction, etc., can solve the problems of short working time, small battery capacity, inconvenient to remove and plug, achieve simple structure and operation, avoid rectification And the effect of frequency conversion and long continuous working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

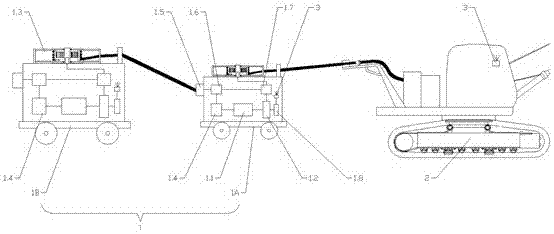

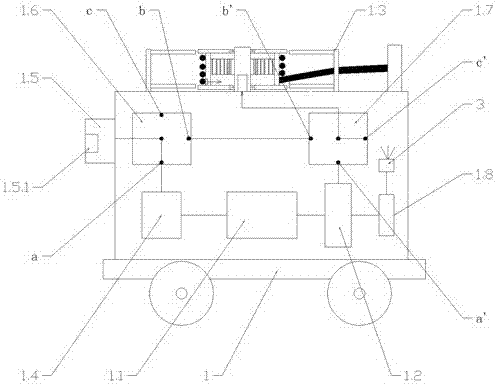

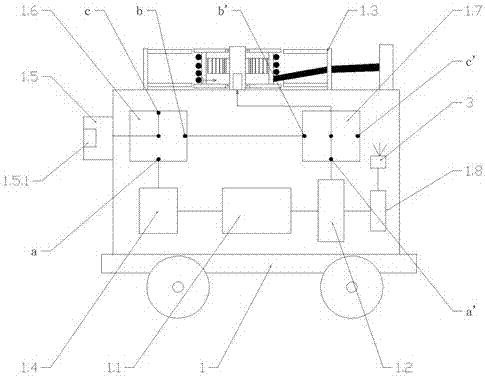

[0027] Specific embodiment one: as figure 1 As shown, the multi-stage series mobile power supply system includes at least one mobile power supply vehicle 1 and electric construction machinery 2 (here is an electric excavator), the mobile power supply vehicle 1 provides electric power for the electric construction machinery 2, and the mobile power supply vehicle 1 One or more units are connected in series to the electric construction machinery 2, and the series connection is that the cable of 1.3 in the cable retracting device of the rear mobile power supply vehicle 1 is connected to the receiving power of the previous mobile power supply vehicle 1. on device 1.5. The mobile power supply vehicle 1 is equipped with a storage battery 1.1, an output power conversion device 1.2, a cable retracting device 1.3, a charging device 1.4, a power receiving device 1.5, an input power conversion switch 1.6 and an output power conversion switch 1.7, and the cable retracting device 1.3 is equ...

specific Embodiment 2

[0038] Specific embodiment two: in combination with embodiment one, each mobile power supply vehicle 1 can have retractable cables ranging from tens of meters to hundreds of meters, by two or more mobile power supply vehicles 1 connected to each other, And on the power receiving device 1.5 of the last mobile power supply vehicle 1, it is connected to the grid power supply, and the manager of the electric construction machinery 2 or the mobile power supply vehicle 1 can communicate with each mobile power supply vehicle 1 through the communication device 3. The control device 1.8 issues instructions to control the input power conversion switch 1.6 and the output power conversion switch 1.7 on each mobile power supply vehicle 1, then it can be designated to allow a certain mobile power supply vehicle 1 to supply power, and the subsequent mobile power supply vehicles 1 Car 1 is charging. This can not only ensure the stable, safe and continuous power supply of the electric engineer...

specific Embodiment 3

[0040] Specific embodiment three: in conjunction with embodiment one, when the electric excavator is working, it needs to rotate left and right, so that it will swing back and forth with the cable. The cable retractable device 1.3 on the smaller mobile power supply vehicle 1A is to solve this problem. set for the problem. Because the cable between the excavator 2 and the movable power supply vehicle 1A of the smaller model will be retracted frequently, the sensitivity of the cable retracting device 1.3 is required to be very high, so the cable retracting device 1.3 cannot be very large, and the cables inside are not large. It can be very long.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com