Double-arm-parallel flat-top tower type crane

A flat-top tower and crane technology, which is applied to the field of double-arm parallel flat-top tower cranes, can solve the problems of difficulty in manufacturing and processing, high quality of lower chords, and low utilization rate of material strength, and achieves the effect of improving utilization rate and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

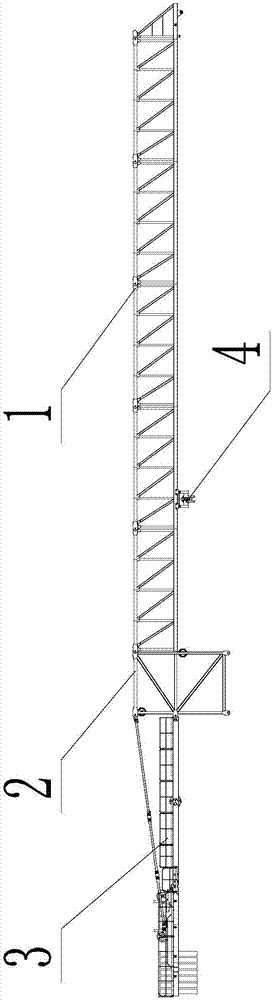

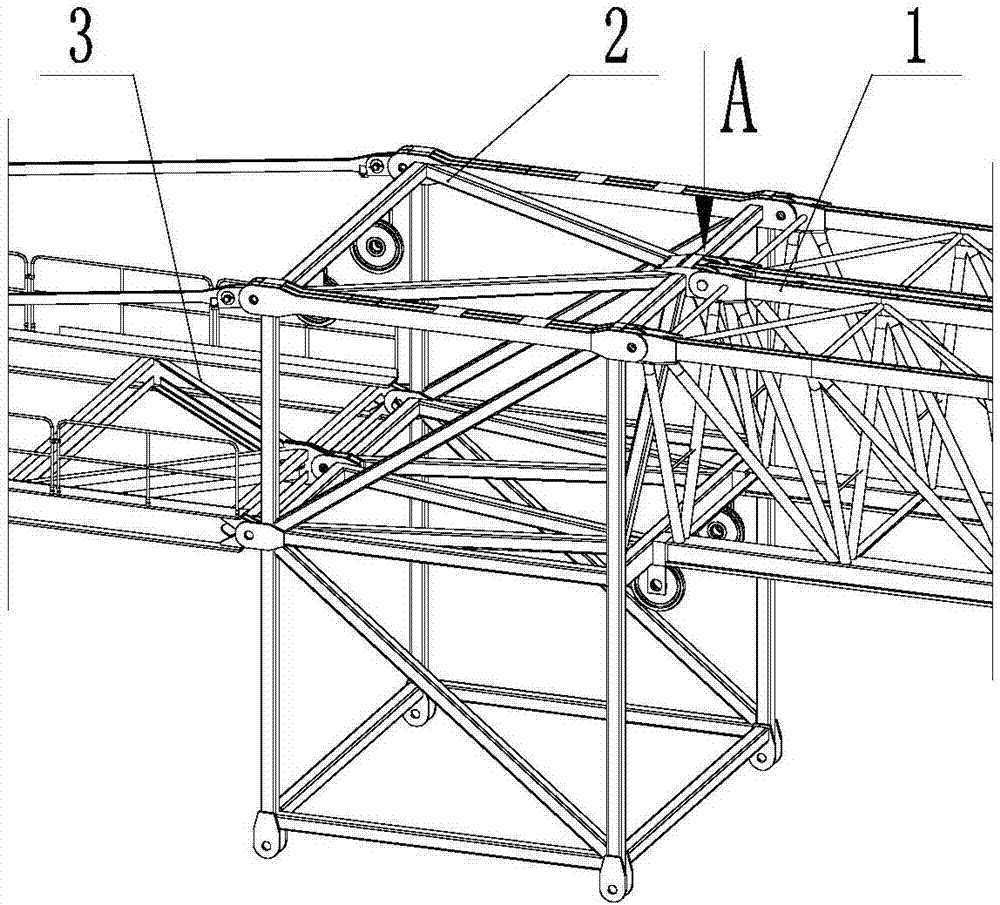

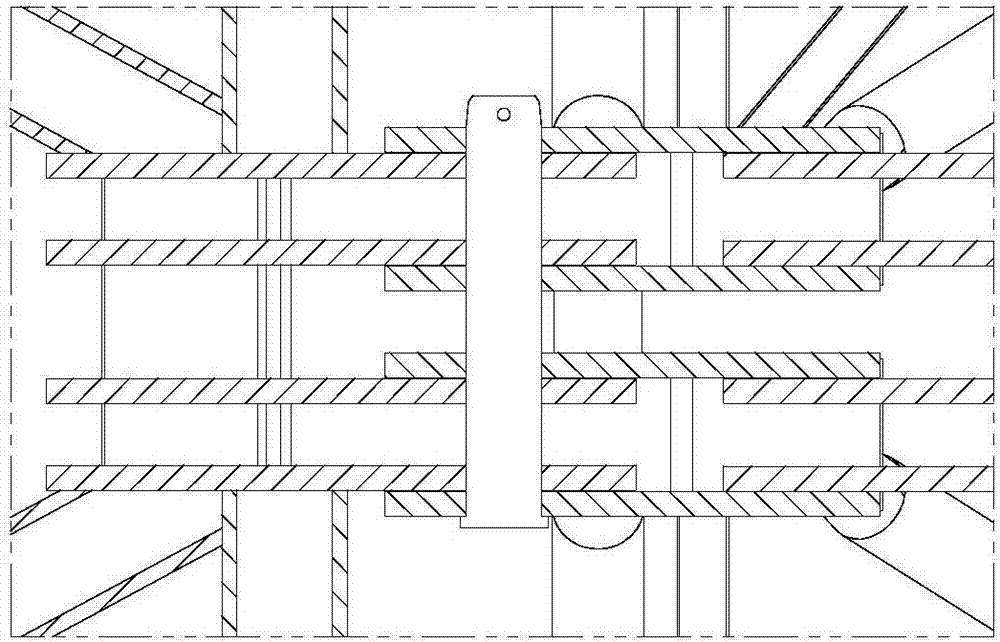

[0053] Example: such as figure 1 As shown in Figure 2, a double-arm parallel flat-top tower crane includes two parallel inverted triangle booms, two independent lifting mechanisms, two independent luffing mechanisms, and two independent luffing trolleys , The balance arm 1 and the swivel joint 2 of the two hoisting mechanisms can be arranged, and the hoisting wire ropes of the two sets of hoisting mechanisms enter the rope guide pulley and the hoisting pulley group of the luffing trolley through the respective guide rope pulleys on the top of the tower respectively, and finally It is fixed on the arm end to form two sets of independent lifting systems on one tower crane; one end of the upper chord of the boom is connected to the connecting lug Ⅰ101 on one side of the rotary joint, and the other end of the upper chord is connected to the next section of the boom through The connecting ear plate II105 is connected, the lower chord 107 is connected with the joint of the swivel jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com