Application of copper-based amorphous alloy as catalytic functional material in wastewater treatment

An amorphous alloy and wastewater treatment technology, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large corrosion loss and short service life of Fe-based amorphous alloys , to achieve the effect of mature production process, low manufacturing cost and excellent long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18

[0026] Examples 1-18: Degradation of Acid Orange II by amorphous alloy strips of different systems.

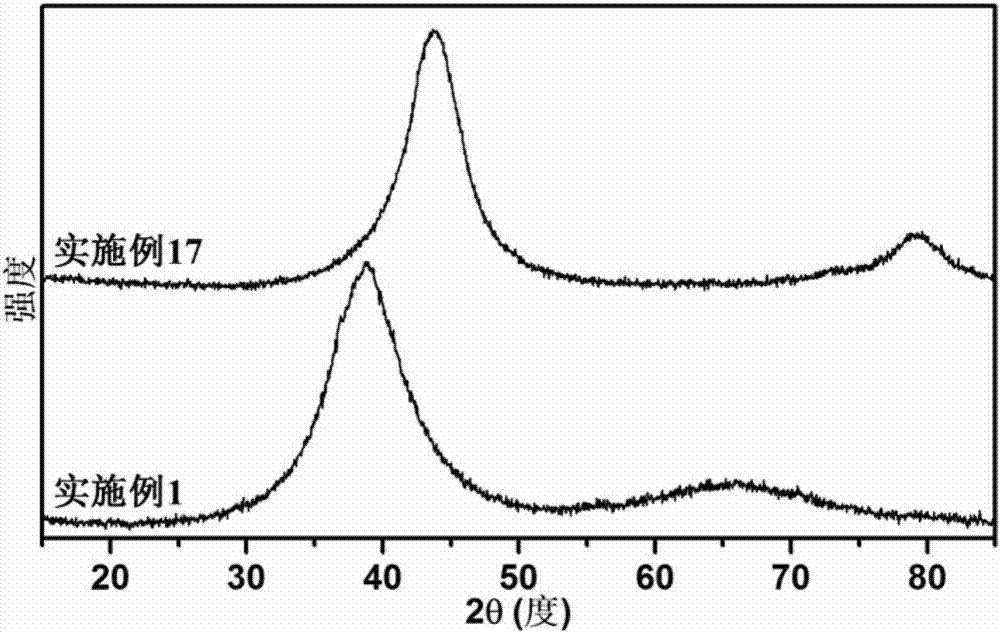

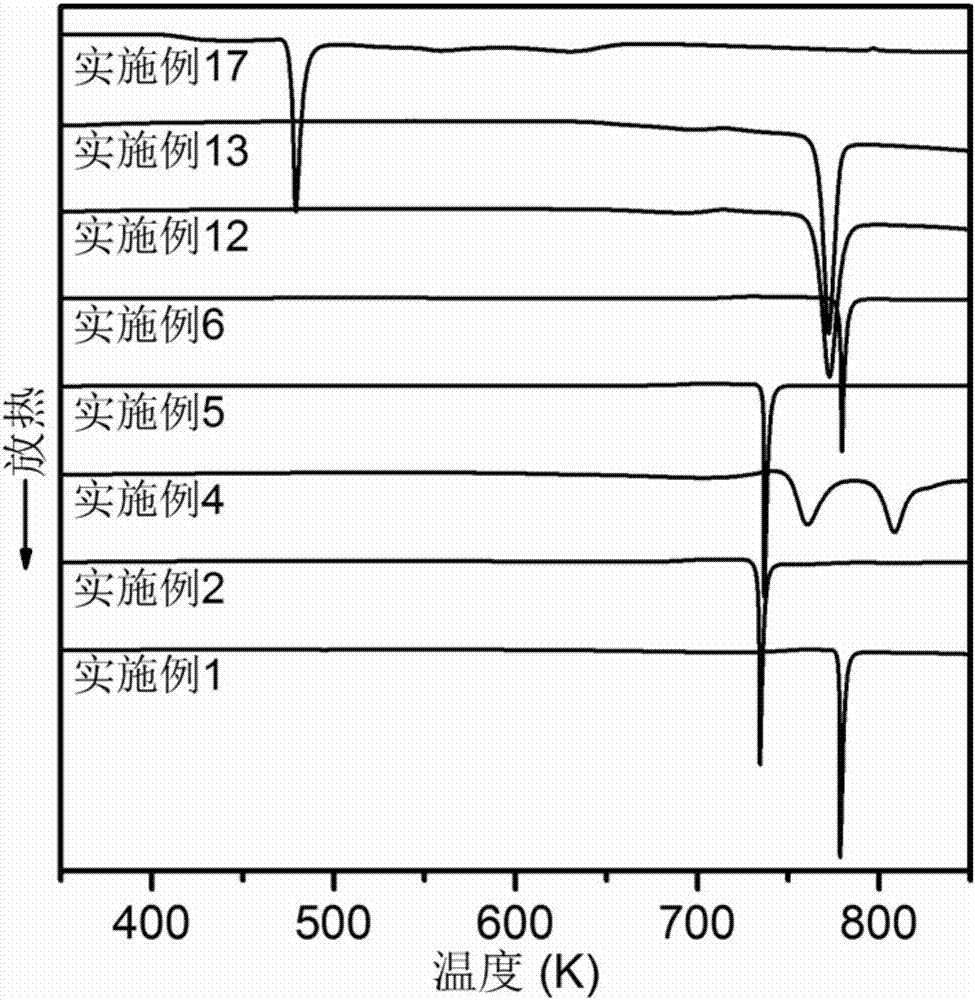

[0027] The amorphous strips were prepared according to the alloy composition in Table 1, and all showed diffuse scattering characteristics of amorphous through XRD characterization. figure 1 Shown are the XRD patterns of Example 1 and Example 17, and the XRD characteristics of other alloy strips are similar. In addition, the DSC curves of some alloys are as figure 2 As shown, obvious crystallization features can be seen.

[0028] Table 1 Embodiment 1-18 corresponding alloy composition

[0029]

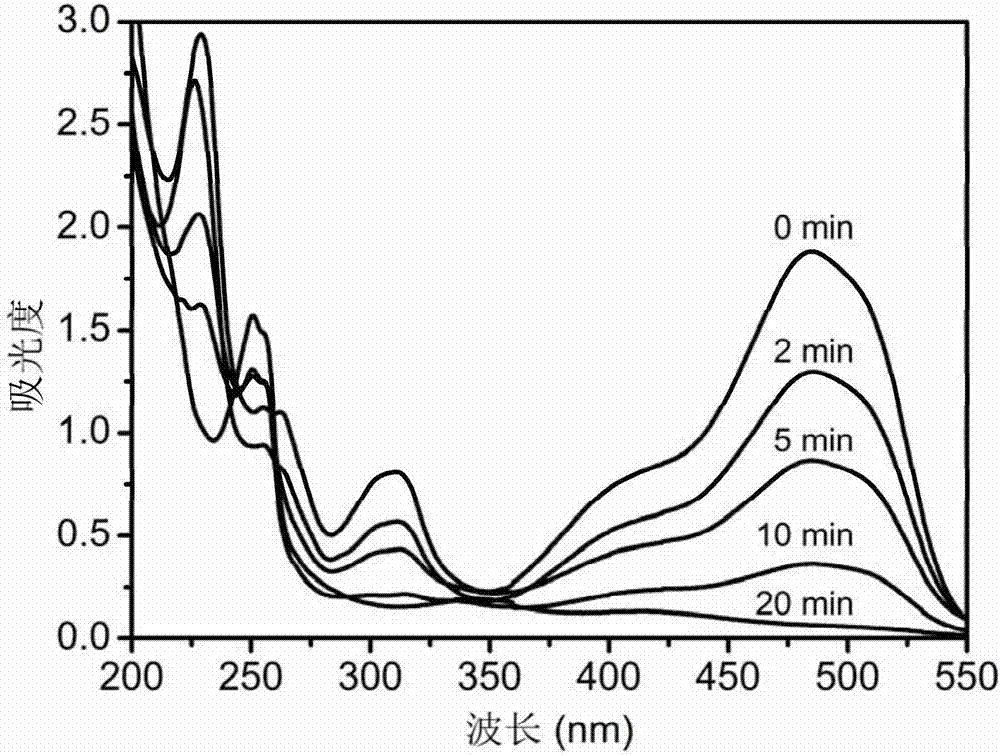

[0030] The degradation process uses an amorphous alloy strip with a surface area of 50 cm 2 , the acid orange II solution concentration is 0.1g / L, the solution volume is 30mL, and the solution temperature is controlled at 60°C. The strips were dropped into the solution and the dye solution was stirred at 200 rpm. After the reaction started, about 3 mL of the solution was tak...

Embodiment 19

[0036] Example 19: Effect of strip dosage on degradation efficiency

[0037] The difference from Example 12 is that the dosage of strips is reduced for experimentation (dye solution volume, concentration, temperature, etc. do not change), and 30cm 2 、20cm 2 、10cm 2 Cu 46 Zr 44.5 Al 7.5 Gd 2 (at.%) experiment, the result is as Figure 5 As shown, it shows that this series of copper-based amorphous alloy strips can still achieve high degradation efficiency with a small amount of dosage.

Embodiment 20

[0038] Example 20: The impact of strip reuse times on degradation efficiency

[0039] The band after degrading Acid Orange II in Example 12 is reclaimed and applied to the degradation experiment of Acid Orange II again (other experimental conditions do not change), and the service life of the band degraded dye wastewater is studied, and the results are as follows Figure 6 shown. It can be seen that Cu 46 Zr 44.5 Al 7.5 Gd 2 (at.%) The strips can still maintain the same degradation efficiency as the first use when they are reused for the 10th time, indicating that the copper-based amorphous alloy has good stability and long service life when degrading dye wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com