A novel needle punching production line

A production line and acupuncture technology, which is applied in the field of new acupuncture production lines, can solve the problems of interlocking signals being easily interfered, and achieve the effects of solving interlocking signals being easily interfered, saving space, and stabilizing linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

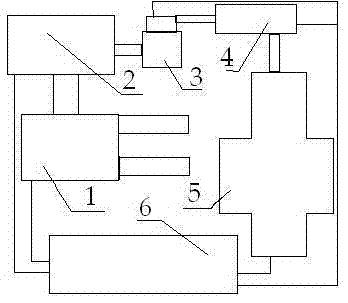

[0009] Referring to the drawings, the present invention includes a central control unit 6, a cleaning unit 1, a cotton storage and feeding unit 2, a carding machine unit 3, a web laying machine unit 4 and a needling machine unit 5. The central control unit 6 passes through the The signal lines are respectively connected with the cleaning unit 1, the cotton storage feeding unit 2, the carding machine unit 3, the laying machine unit 4 and the acupuncture machine unit 5, the cleaning unit 1, the cotton storage feeding unit 2, the carding machine unit. 3. The web laying machine unit 4 and the acupuncture machine unit 5 are respectively provided with a motor and a sensor, and a PLC control module and a main control module are arranged in the central control unit 6. The PLC control module communicates with the cleaning unit respectively through the Profibus communication protocol. 1. The cotton storage and feeding unit 2, the carding machine unit 3, the laying machine unit 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com