A masonry device and method of use thereof

A masonry and block technology, which is applied in construction, building structure, construction material processing, etc., can solve the problems of non-conforming thickness, insufficient ash joints, large quality fluctuation, etc. Uniform thickness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the following embodiments.

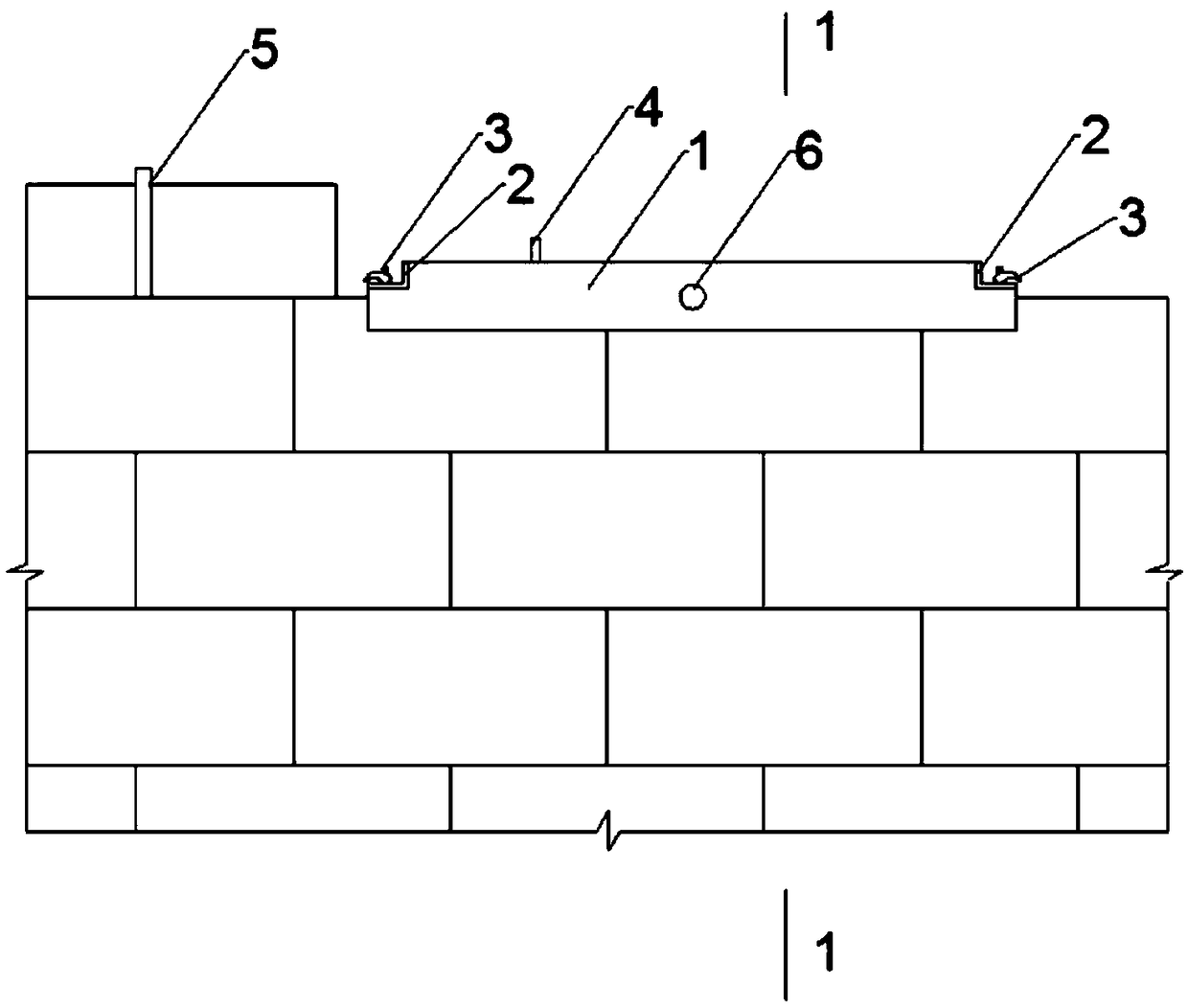

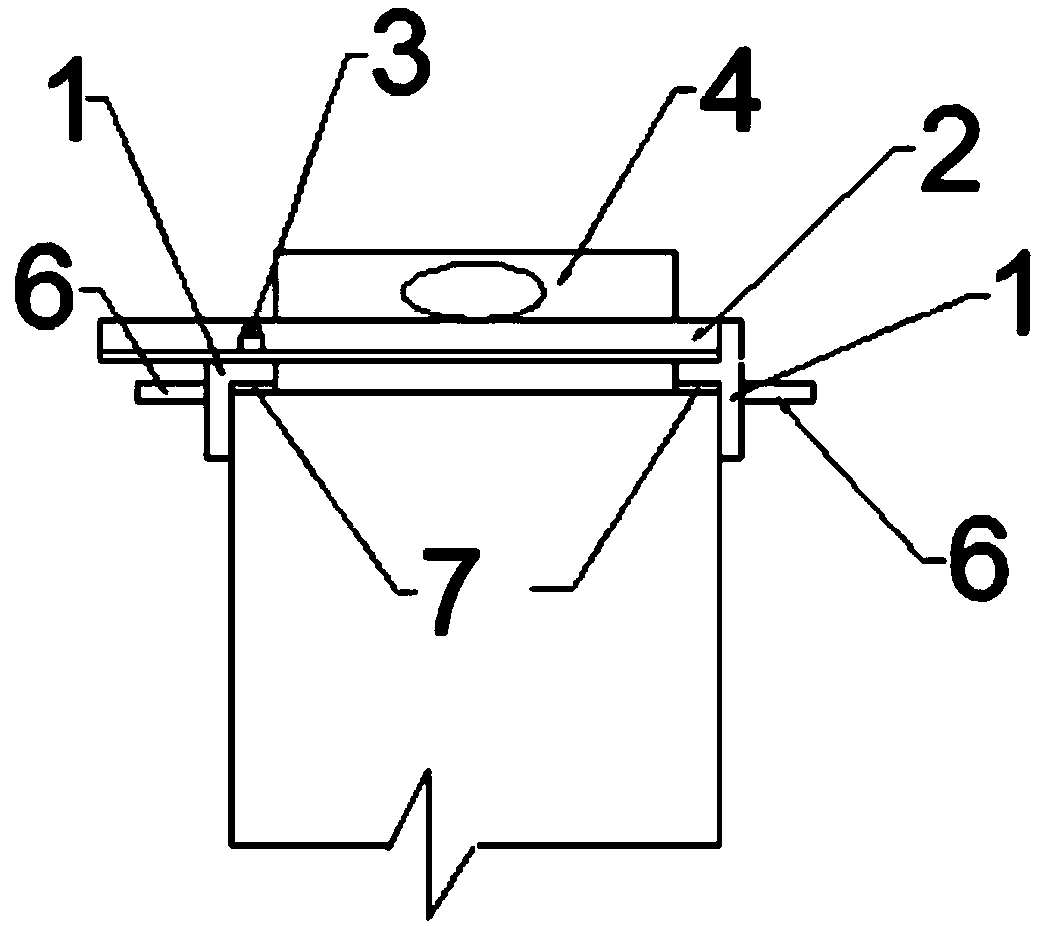

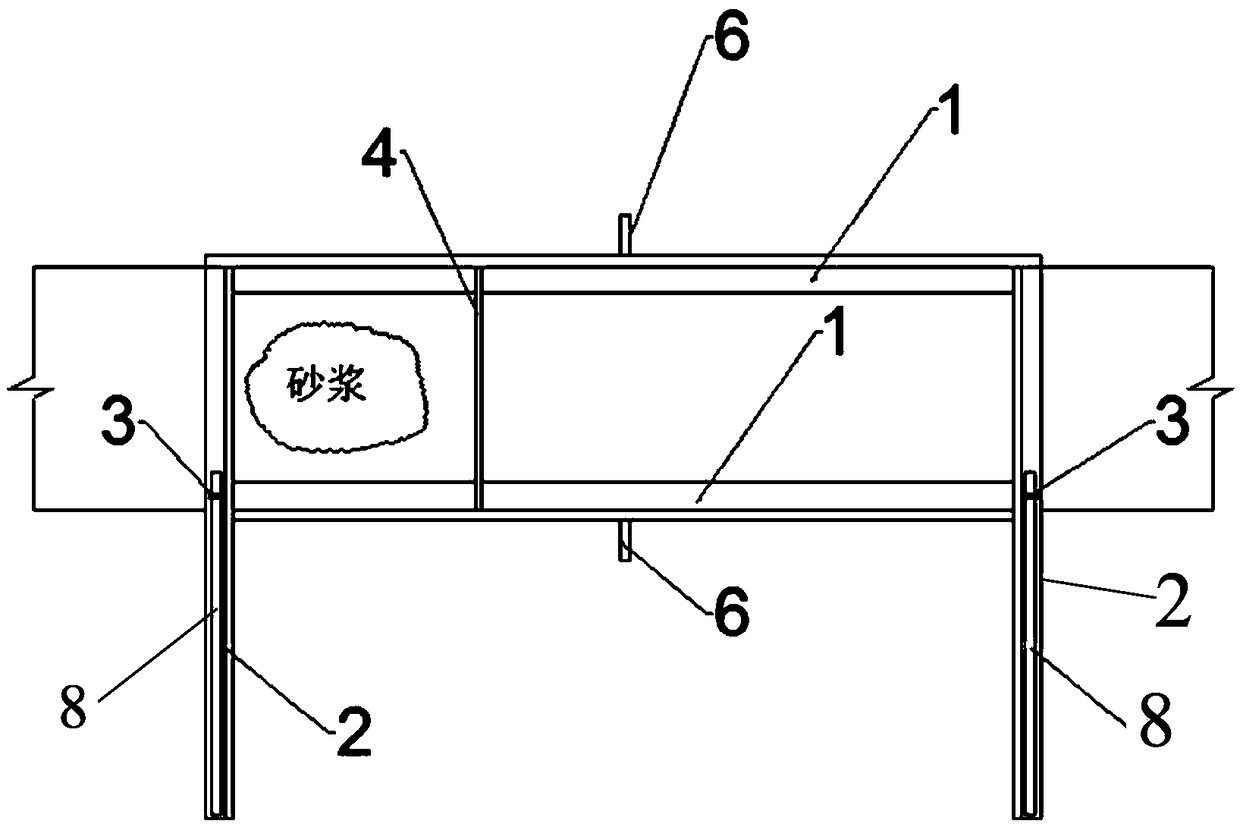

[0030] Such as Figure 1 to Figure 4 As shown, it is a schematic structural diagram of the masonry device provided by the embodiment of the present invention. It includes a horizontal mortar joint device and a vertical mortar joint device 5 .

[0031] The horizontal mortar joint device includes two opposite slide rails 1 , two first adjustment frames 2 , two first fasteners 3 , a dust scraper 4 , two handles 6 and a wear-resistant layer 7 . The two sliding rails 1 are respectively arranged on both sides of the masonry along the horizontal direction of the masonry. The bottoms of the two slide rails 1 can slide horizontally relative to the masonry. The inner sides of the two slide rails 1 are provided with slide grooves. The dust scraping board 4 can slide along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com