Tangent opposite-pull pulling cables and wind power generation tower using cables

A cable and tangent technology, used in wind power generation, installation/support of wind turbine configuration, towers, etc., can solve the problems of impact, inability to meet structural strength and rigidity, power generation efficiency and structural safety disadvantages, and achieve improved resistance to Fatigue performance, avoiding the effect of welded connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Referring to the accompanying drawings, a detailed description will be given of the tangent-to-stay cable wind power tower provided by the present invention in combination with an embodiment.

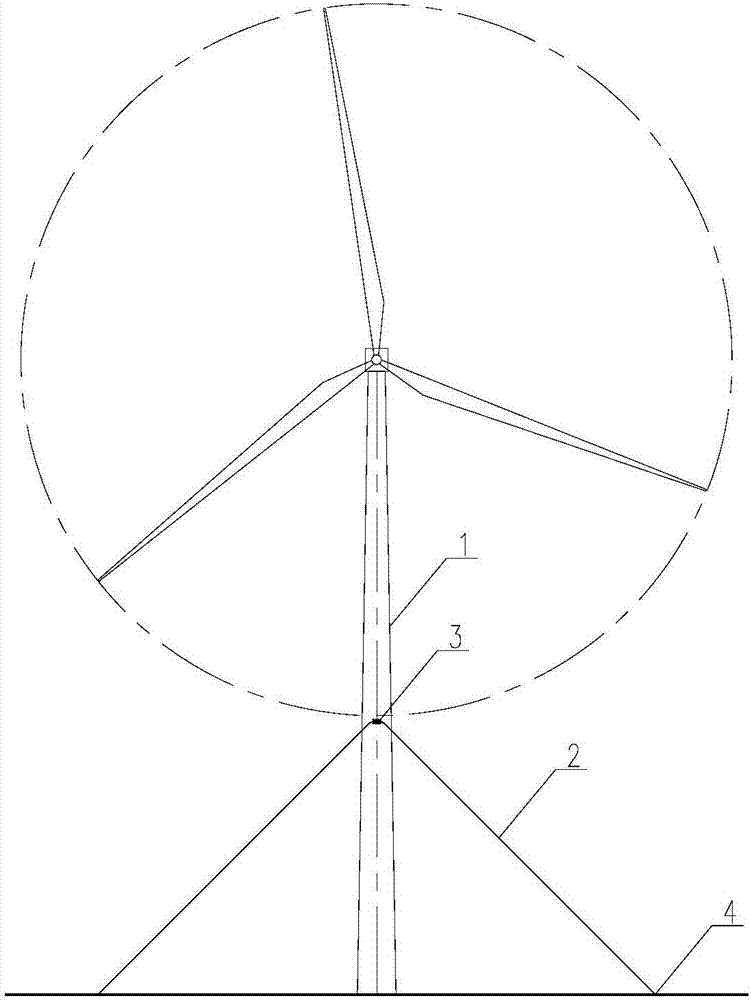

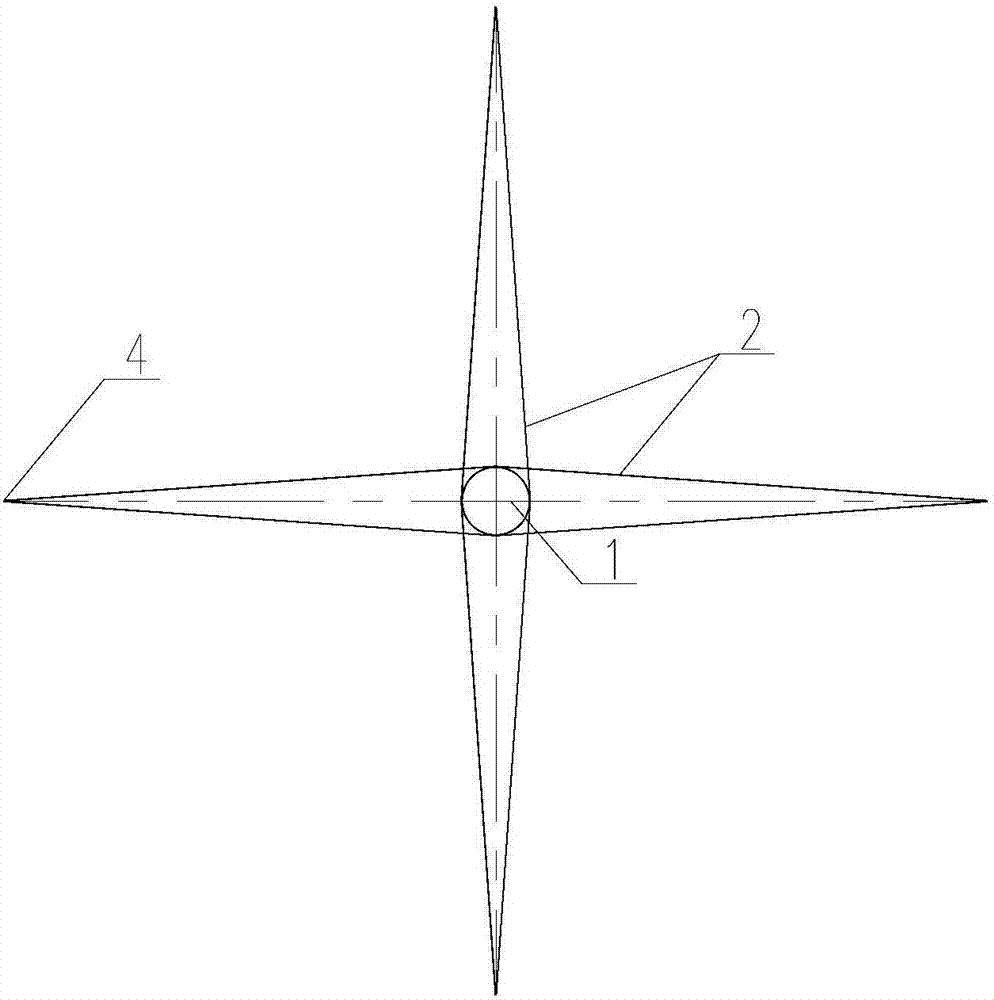

[0024] refer to figure 1 with figure 2 , The structure of the wind power generation tower in this embodiment is provided with two sets of tangent pair stay cables, the two sets of stay cables form a cross, and there are four prestressed stay cables in total.

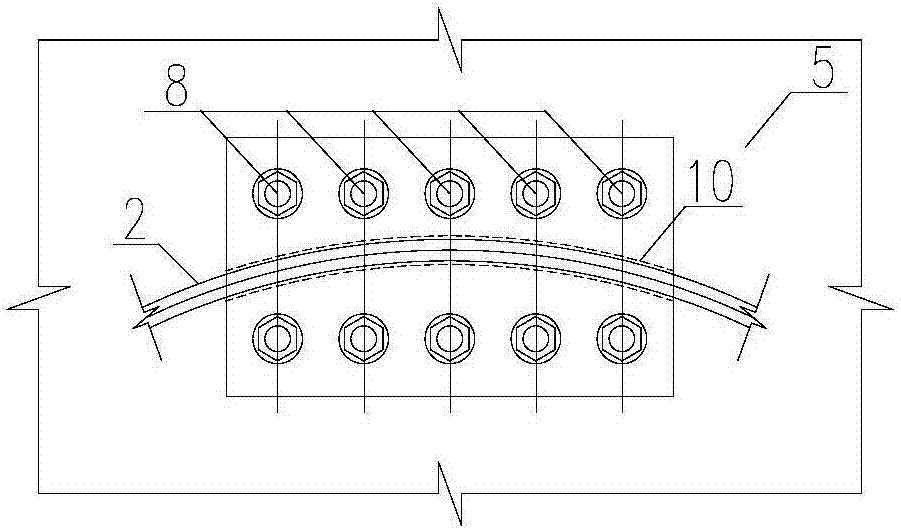

[0025] The middle part of each prestressed cable 2 is fixed on the tower tube 1 of the wind power generation tower through the bolt node 3, and goes around the tower tube to the opposite direction, and the two ends are fixed on the anchor point 4. Such as image 3 with Figure 4 As shown, the bolt node 3 is located below the impeller of the wind power tower and is arranged on the tower wall 5 , including an upper splint 6 , a lower splint 7 , a pressure plate 9 and bolts 8 . Among them, the thickness of the upper splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com