Composite cross arm and composite pole tower

A composite pole and cross-arm technology, which is applied to towers, electrical components, insulators, etc., can solve problems such as the unsatisfactory effect of the uniform electric field of the common voltage equalizing ring and the complex structure of the voltage equalizing ring configuration scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

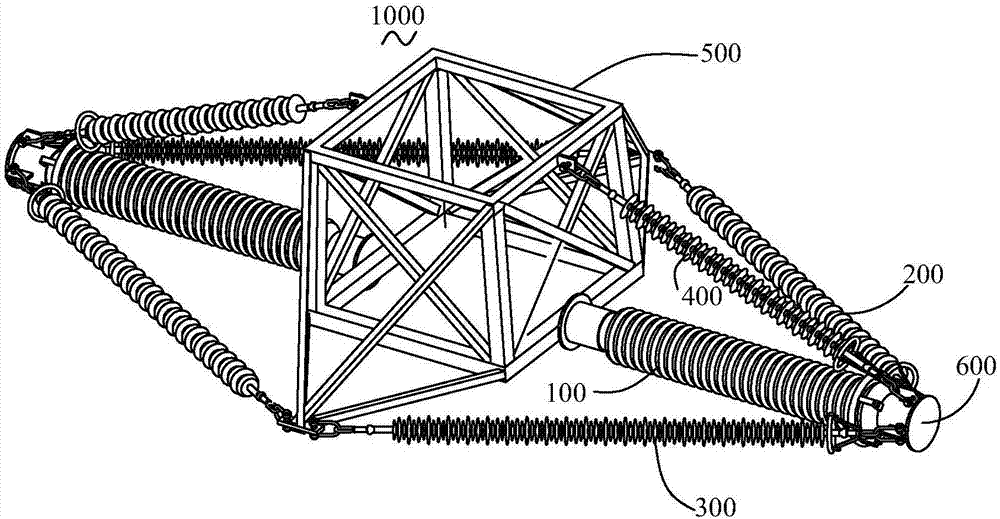

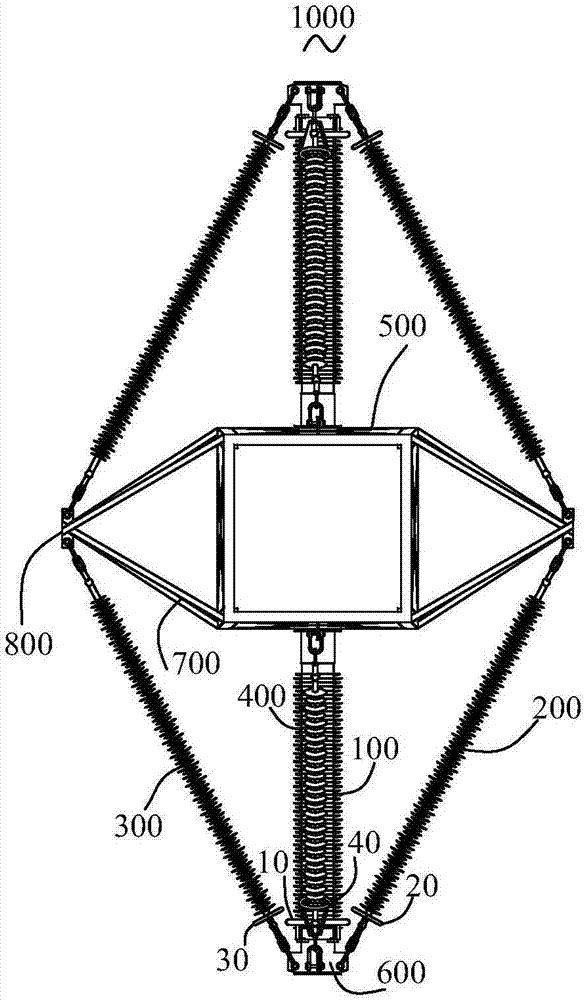

[0030] Such as figure 1 As shown, the composite cross-arm in this embodiment includes a row of cross-arm insulators 100 , two rows of horizontal cable-stayed insulators 200 , 300 and a row of upper cable-stayed insulators 400 . The cross-arm insulator 100 and the two rows of horizontal cable-stayed insulators 200 and 300 are located in the same horizontal plane, and the upper cable-stayed insulator 400 is located directly above the cross-arm insulator 100 .

[0031] The cross-arm insulators 100 are arranged in a straight line, one end is connected to the tower body 500 of the composite pole tower 1000 , and the other end is the terminal 600 . The two rows of horizontal cable-stayed insulators 200, 300 are in the shape of a line and are respectively located on both sides of the cross-arm insulator 100, and form a V shape relative to each other. The top ends are respectively connected to the ends 600 of the cross-arm insulators 100 , and one end of the V-shaped opening formed b...

Embodiment 2

[0040] Such as Image 6 As shown, this embodiment takes the horizontal cable-stayed insulator 200 as an example to describe the connection device 50 between the horizontal cable-stayed insulator 200 and the auxiliary grading ring 20 . For the cross-arm insulator 100 , the horizontal cable-stayed insulator 300 and the upward cable-stayed insulator 400 , the connection device 50 is applicable.

[0041] Such as Image 6 , Figure 7 As shown, the connecting device 50 includes a connecting piece 51 and a bracket 52, two connecting pieces 51 are evenly distributed on the same side of the auxiliary equalizing ring 20, the connecting piece 51 is a plate-shaped piece, and one end is fixed to the auxiliary A through hole 511 is defined on the pressure equalizing ring 20 and at the other end away from the auxiliary pressure equalizing ring 20 . There are two brackets 52, which are used in conjunction with the connector 51. One end of the bracket 52 is provided with a bracket through h...

Embodiment 3

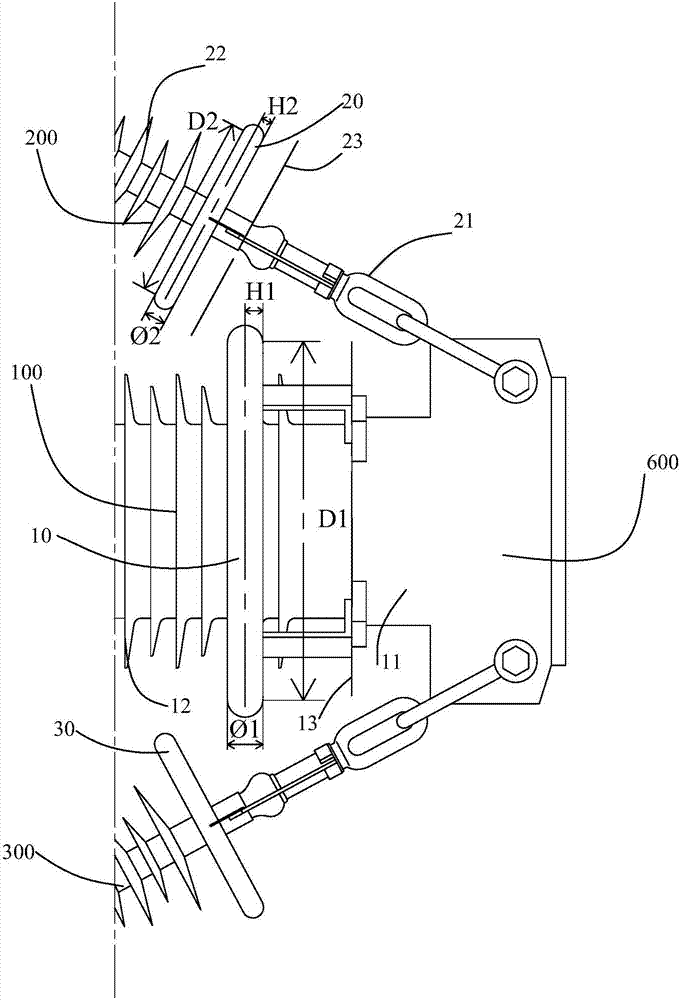

[0045] Such as Figure 8 As shown, this embodiment takes the cross-arm insulator 100 as an example to describe the connection device 60 between the cross-arm insulator 100 and the main grading ring 10 . The connection device 60 is applicable to the two rows of horizontal cable-stayed insulators 200 , 300 and the upper cable-stayed insulator 400 .

[0046] Such as Figure 8 , Figure 9 As shown, the connecting device 60 includes a connecting piece 61 and a bracket 62. There are four connecting pieces 61 and they are evenly distributed on the same side of the main pressure equalizing ring 10. The connecting piece 61 includes a supporting part 611 and a connecting part 612. The supporting part 611 is perpendicular to The outer surface of the main pressure equalizing ring 10 is also perpendicular to the connecting portion 612, and the connecting portion 612 points to the inner side surrounded by the main pressure equalizing ring 10, and the end of the connecting portion 612 away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com