Width-adjustable formwork trolley for pipe galleries

A trolley and pipe gallery technology, which is applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of low equipment reuse rate, low labor intensity of workers, and low construction efficiency, and achieve high formwork reuse rate , Good shock absorption and obstacle-crossing function, high reusability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

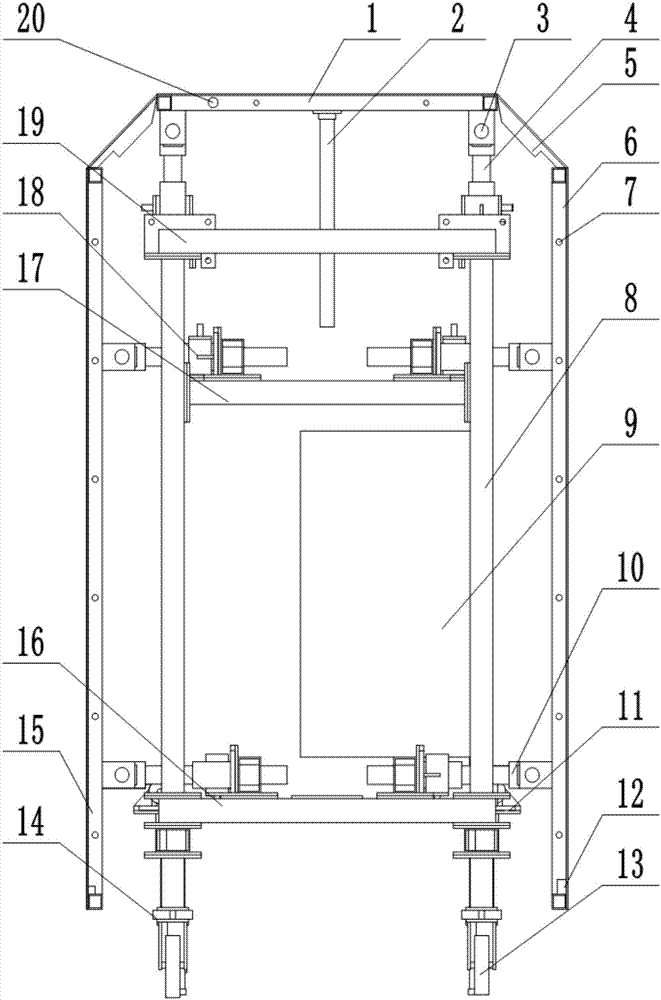

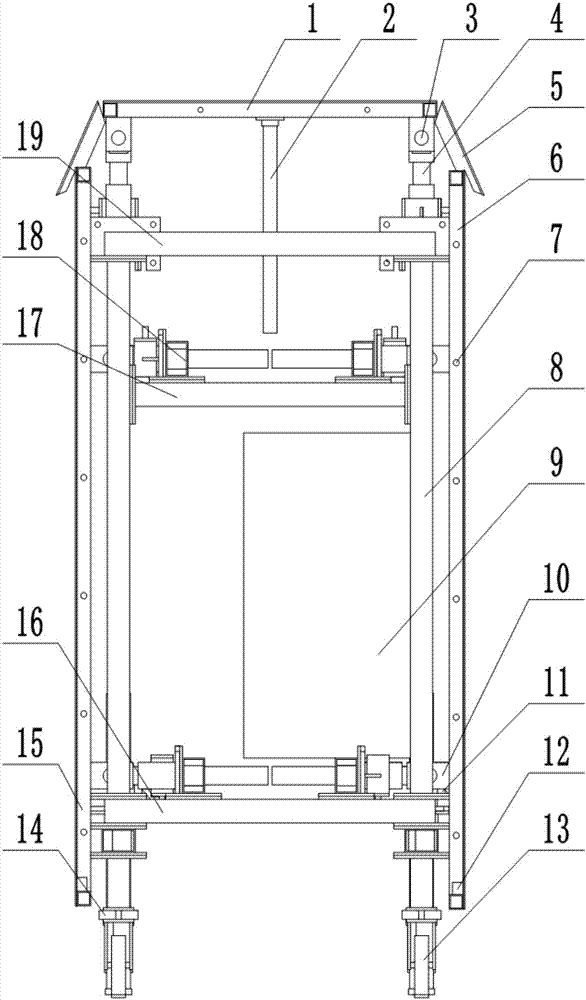

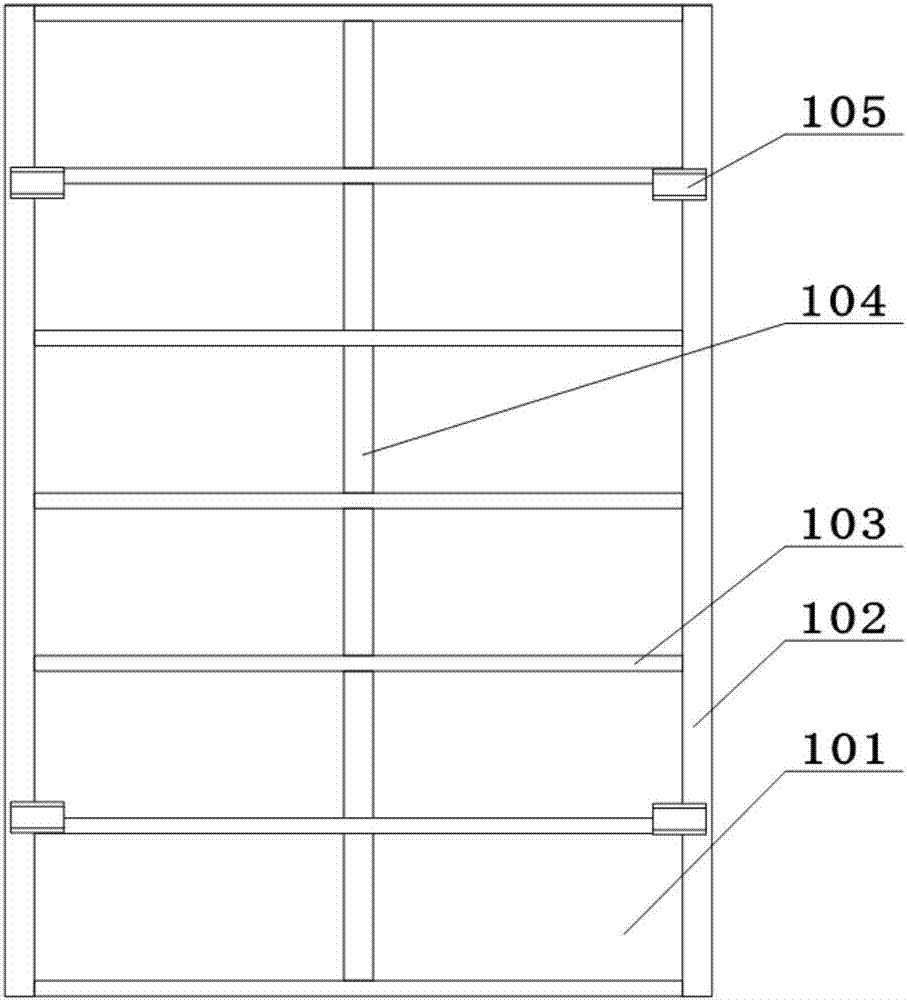

[0031] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-5 As shown, an adjustable width pipe gallery formwork trolley is characterized in that: the trolley includes a formwork assembly, a telescopic mechanism, a variable width frame, a walking mechanism, a monitoring mechanism and a control cabinet 9, and the formwork assembly includes Top formwork 1, left formwork 15, right formwork 6 and bevel formwork 5; The telescopic mechanism includes left screw motor 18, right screw motor 10, top hand screw 2, top screw motor 4 and the bottom screw motor 11; the variable width frame includes a column 8, a bottom telescopic crossbeam 16, a middle telescopic crossbeam 17 and a top telescopic crossbeam 19; Mechanism 12 includes a pressure sensor and a distance sensor.

[0032] The variable width frame includes three groups of six columns 8 arranged front and back, a bottom telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com