A Blasting Method for Sloping Ore Body Cutting Uphill and Pulling Troughs

A technology of pulling troughs and ore bodies, which is applied in blasting and other directions, can solve problems such as prominent safety hazards, limited climbing ability, and low efficiency of personnel and equipment, and achieve the effects of accelerating mining speed, improving ore quality, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

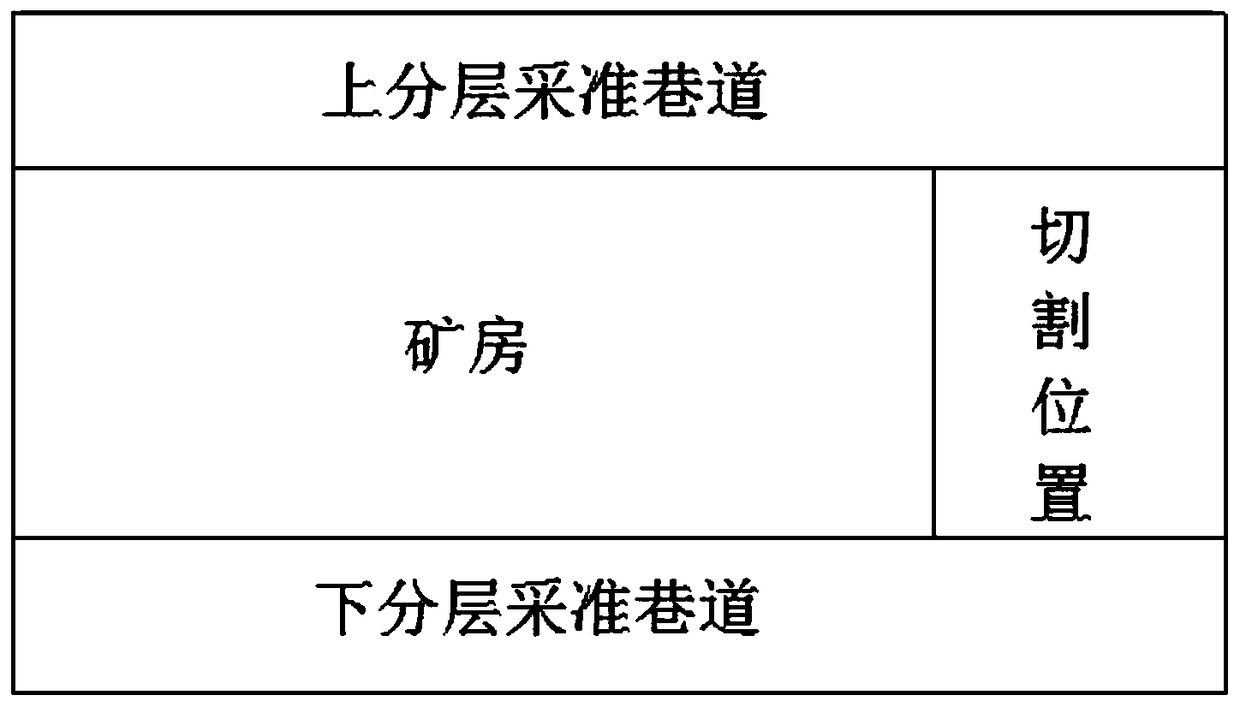

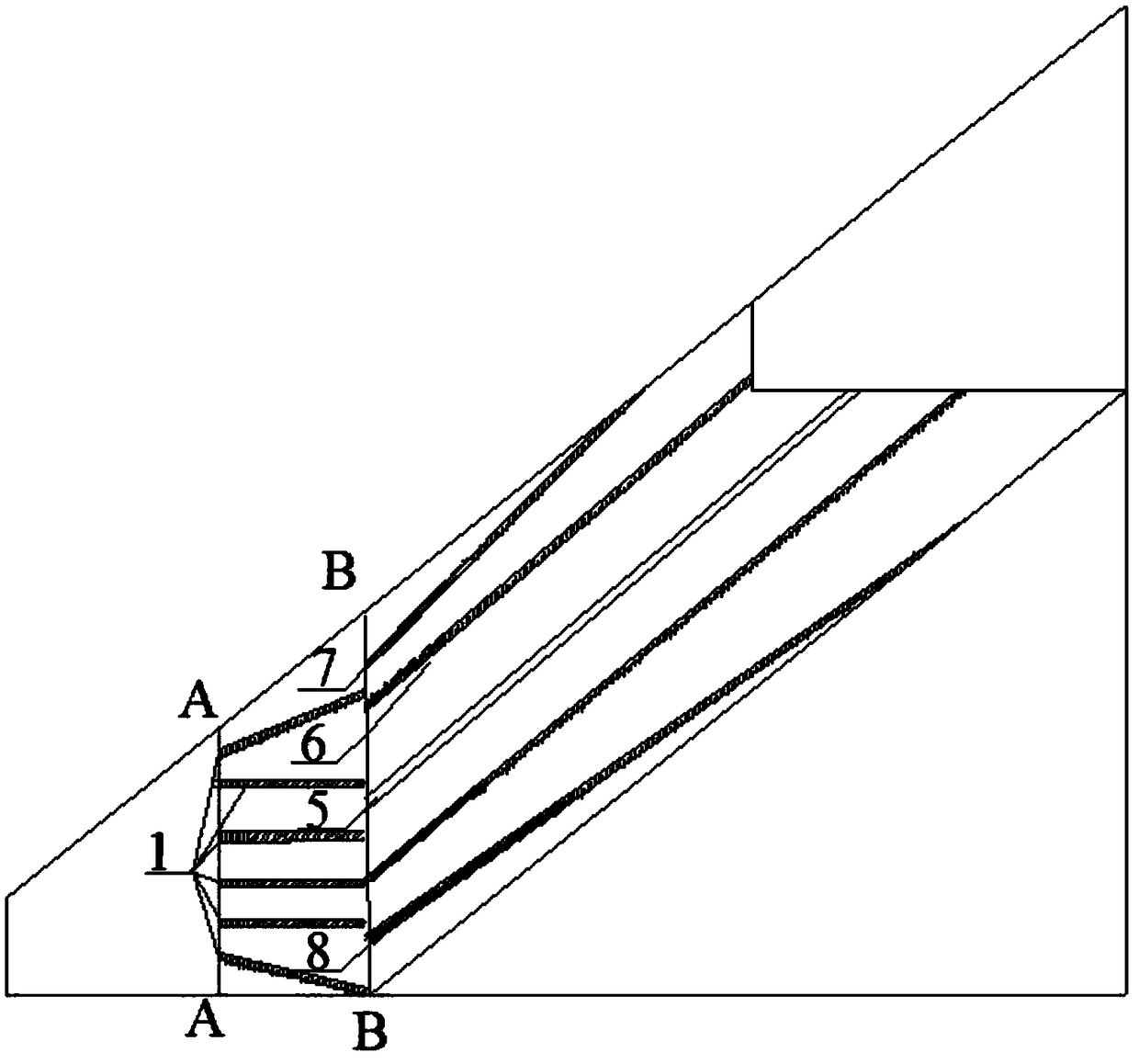

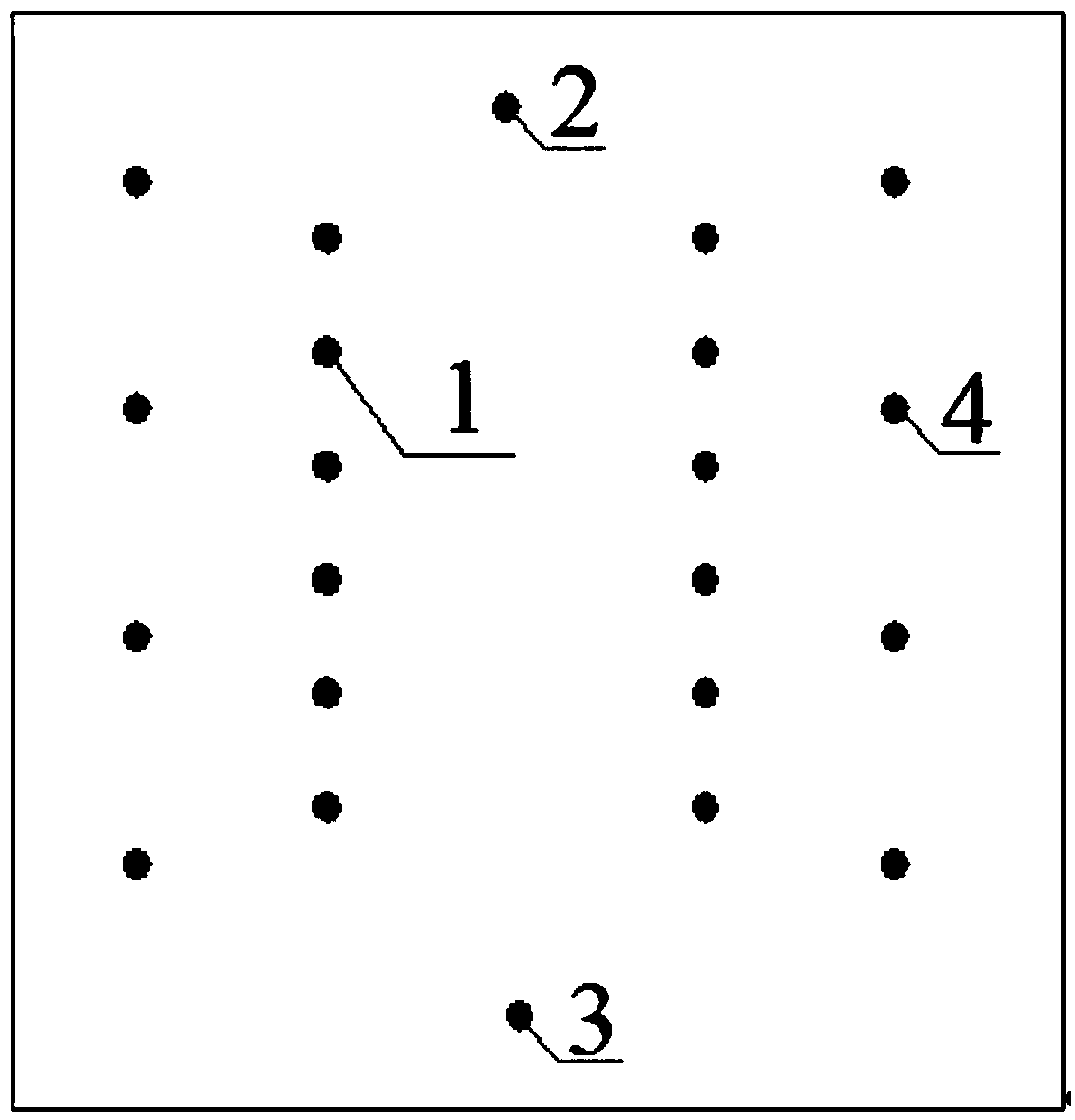

[0023] Refer to the attached figure 1 , 2 , 3, 4 and 5, the inclined ore body cutting uphill blasting method of the present invention divides the cutting uphill blasting into two times, first using the shallow hole rock drilling jumbo to utilize the oblique eye cutting hole 1 and the oblique eye cutting roof hole 2. Bottom plate hole with slant hole 3. Auxiliary hole 4 with slant hole for blasting and excavation on the high side, increasing the compensation space and free surface for secondary blasting, and reducing the length of cutting uphill; then use the medium and deep hole rock drilling rig The car is used for rock drilling, and the large hole 5 in the center of the straight hole cutting is used to further increase the bursting space of the straight hole blasting and reduce the minimum resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com