Preparation method of surface plasmon resonance chip based on hyperbranched zwitterionic polymethylacrylcysteine modification

A polymethacryl-based and methacryl-based technology is applied in the field of ion resonance spectrometer anti-pollution chip preparation, which can solve the problems of surface contamination of the sensor chip, false positives, and reduce the accuracy of quantitative detection, and achieve label-free rapid Detection, high solid load, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

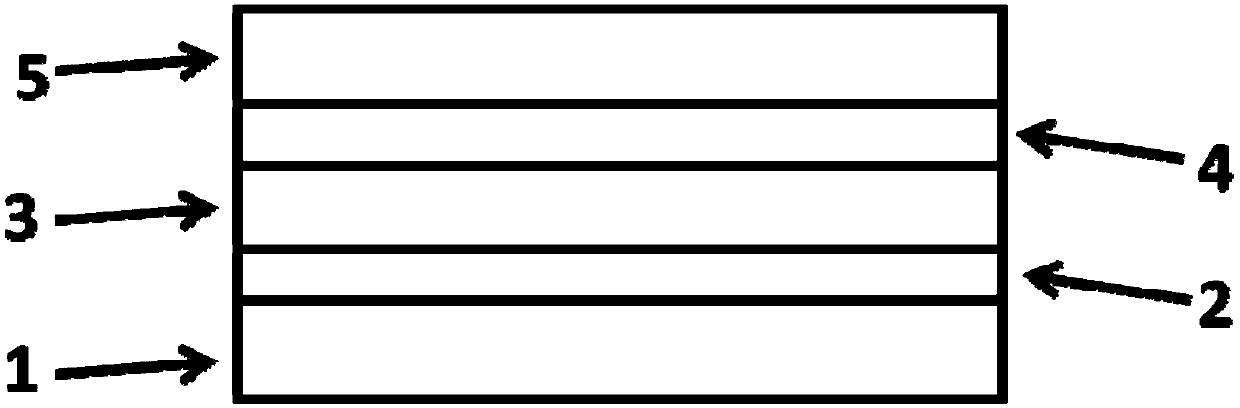

[0032] A method for preparing a surface plasmon resonance chip based on hyperbranched zwitterionic polymethacrylcysteine modification, comprising the following steps:

[0033] a) Electron beam evaporation coating technology is used to coat a layer of 2nm thick chromium layer and a layer of 48nm thick gold film on the BK7 glass substrate to obtain a bare gold chip.

[0034] b) Immerse the bare gold chip in a mixed solution of 98wt% concentrated sulfuric acid and 30wt% hydrogen peroxide (volume ratio 7:3), soak for 2 hours at room temperature, then take it out, wash it with deionized water for 3 times, and dry it with nitrogen for later use.

[0035] c) Synthesis of methacrylcysteine monomer: Dissolve 24.98mmol cysteine with 20mL deionized water, add 27.47mmol 2-acrylic acid-2-hydroxy-1,3-propanediester and 29.4 μmol xylylphosphorus, stirred and reacted at 20°C for 2h. The reacted solution was extracted once with ethyl acetate and twice with dichloromethane, and the obtai...

Embodiment 2

[0043] A method for preparing a surface plasmon resonance chip based on hyperbranched zwitterionic polymethacrylcysteine modification, comprising the following steps:

[0044] a) A 3nm thick chromium layer and a 47nm thick gold film were coated on the BK7 glass substrate by electron beam evaporation coating technology, and a bare gold chip was obtained.

[0045] b) Dip the bare gold chip into a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide (volume ratio 7:3) for 2 hours at room temperature. Then take it out and wash it three times with deionized water, and dry it with nitrogen gas for later use.

[0046] c) Dissolve 24.98mmol of cysteine in 20ml of deionized water, add 27.47mmol of 2-acrylic acid-2-hydroxy-1,3-propanediide and 29.4μmol of xylylphosphine, and stir at 30°C for 1h . The reacted solution was extracted once with ethyl acetate and twice with dichloromethane, and the obtained aqueous monomer solution was lyophilized to obtain a whit...

Embodiment 3

[0054] The hyperbranched zwitterionic polymethylacrylcysteine SPR chip obtained in Example 1 was attached to the prism of the SPR system with asphalt. Phosphate buffer with a pH of 7.4 was used as the mobile phase at a flow rate of 10 μL / min. After the baseline is stable, inject 100 μL of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC, the concentration is 0.4M) and N-hydroxysulfosuccinimide into the quantitative loop A mixed solution of amine (NHS, concentration 0.1M) is used to push the EDC / NHS solution to the surface of the chip through the mobile phase. After 15 minutes, 100 μL of goat immunoglobulin (anti-IgG, 1 mg / mL) was injected, and the anti-IgG solution was pushed to the surface of the chip through the mobile phase. After blocking with ethanolamine, the SPR sensor chip with immobilized anti-IgG was obtained after 30 minutes.

[0055] The hyperbranched zwitterionic polymethacrylcysteine SPR chip obtained above was attached to the prism of the SPR system with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com